Mixing, baffling and guiding device

A guiding device and mixing technology, applied in mixers, transportation and packaging, dissolving and other directions, can solve the problems of poor mixing effect of materials, disrupting the flow ability of logistics, etc., and achieve the effect of uniform mixing of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

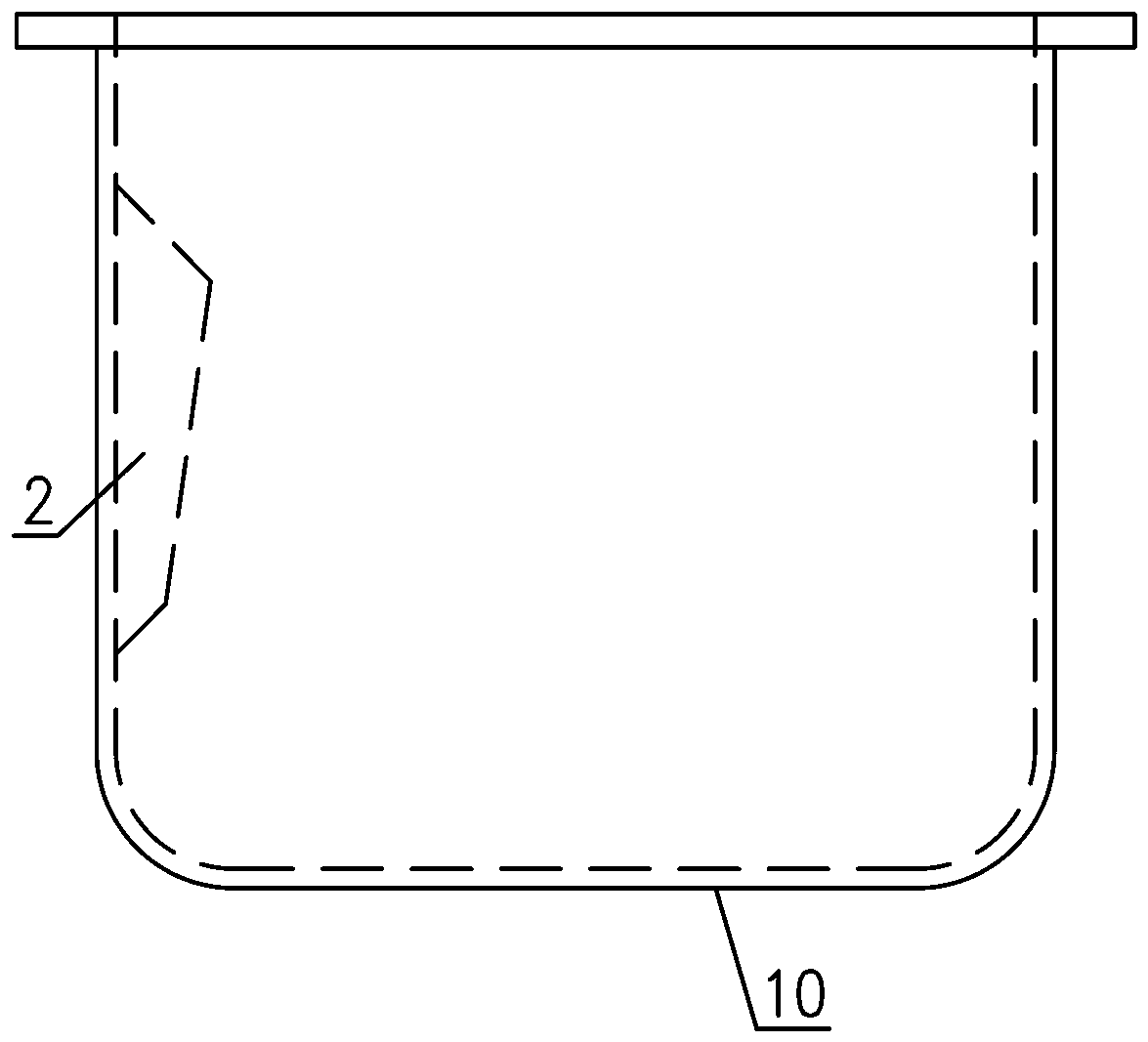

[0022] The mixing baffle guide device is used in the mixing tank, and is fixedly attached to the inner wall of the upper section of the mixing tank when in use. For the convenience of description, here, the inner wall close to the mixing tank is called inward, and the inner wall away from the mixing tank is called outward. Such as figure 1 and Figure 4 As shown, the mixed material baffle guide device described in this embodiment is composed of a fan-shaped upper sealing plate 1, a bent plate 2 and a fan-shaped lower sealing plate 3 to form a whole. The bent plate 2 is a V-shaped plate structure formed by bending the left and right sides around the middle bending line 4 to the inside, and the upper edge of the bent plate 2 forms a V-shaped side with high sides and low middle. , the lower edge of the bent plate 2 forms an inverted V-shaped side with low sides and high middle. The two straight edges of the upper sealing plate 1 are sealed and spliced with the upper edge of ...

Embodiment 2

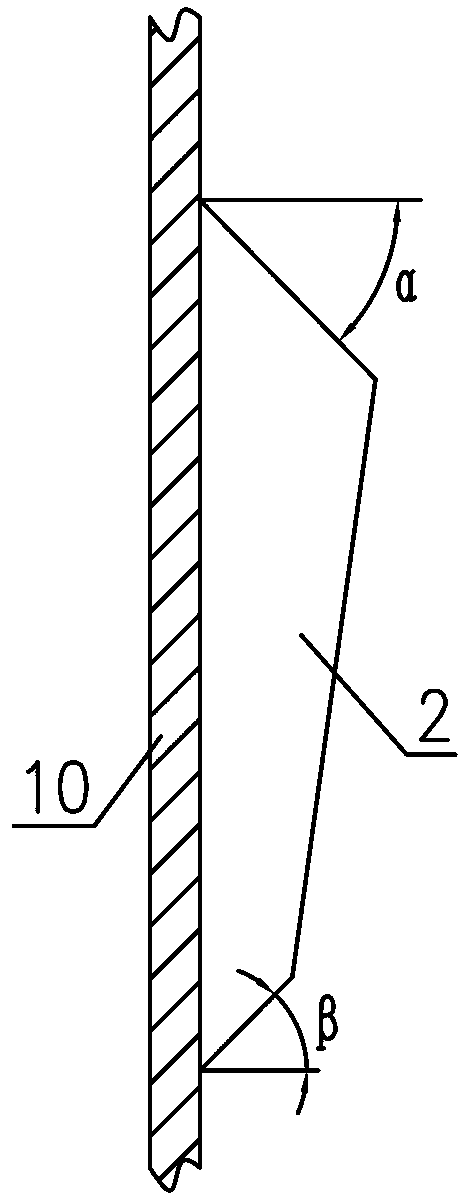

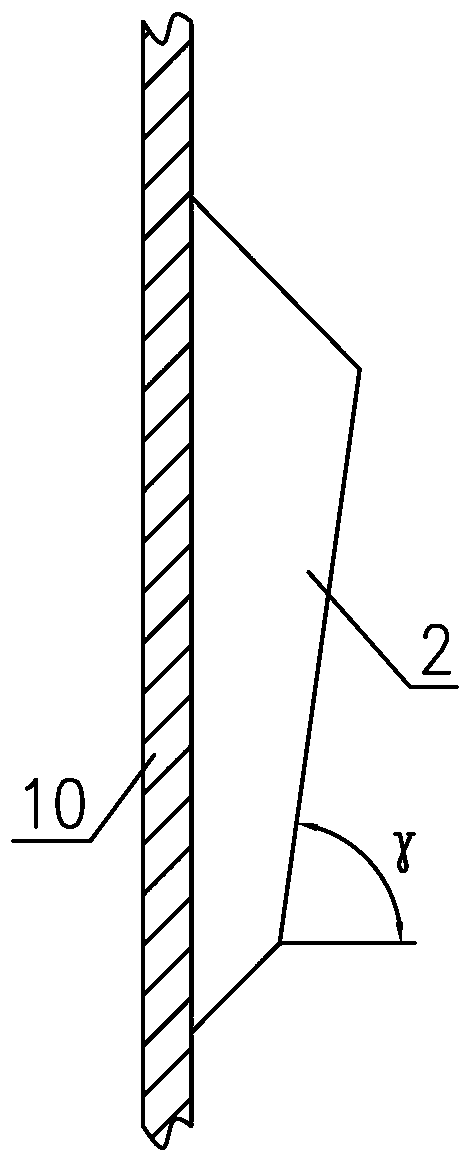

[0024] Such as figure 2 , image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the upper edge of the bent plate 2 forms an asymmetric V-shaped edge with two sides high and the middle part low, and the lower edge of the bent plate 2 forms an asymmetrical V-shaped side with two sides low and the middle part high. Asymmetric inverted V-shaped sides. The angle α between the upper sealing plate 1 and the horizontal plane is 60°-70°, and the angle β between the lower sealing plate 3 and the horizontal plane is 60°-70°.

[0025] The area of the upper sealing plate 1 described in this embodiment is larger than the area of the lower sealing plate 3 , specifically: the area of the upper sealing plate 1 is 1.5 to 2 times that of the lower sealing plate 3 .

[0026] The length of the arc-shaped edge 5 of the upper sealing plate 1 described in this embodiment is greater than the length of the arc-shaped edge 6 of the lower sealing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com