Double-shaft double-speed stirring tank for foamed concrete

A foamed concrete and mixing tank technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of general effect, poor foaming effect, poor working environment, etc., and achieve uniform material mixing and high quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

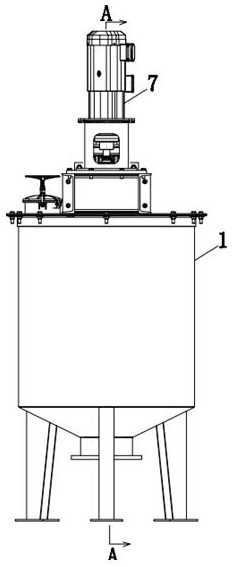

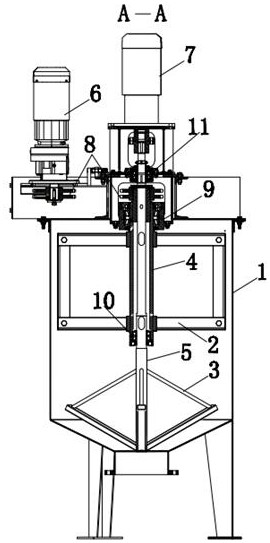

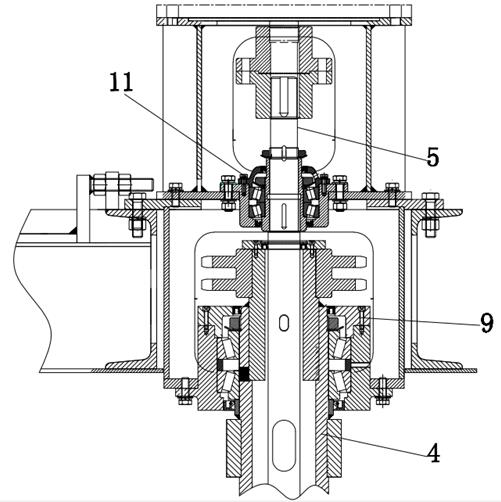

[0024] Such as Figure 1-5 As shown, a foamed concrete biaxial and double-speed mixing tank provided by the embodiment of the present invention includes a tank body 1, a stirring mechanism, a discharge port, a water inlet and a feeding port, and the stirring mechanism includes an upper agitator 2, a lower Agitator 3, outer shaft 4 and mandrel 5, the upper agitator 2 is fixed on the outer shaft 4, and rotates synchronously with the outer shaft 4, the outer shaft 4 is a hollow shaft, and the mandrel 5 is made of a hollow The center of the shaft passes through and extends to the bottom of the tank body 1. The lower agitator 3 is fixed on the mandrel 5 and rotates synchronously with the mandrel 5. The outer shaft 4 and the mandrel 5 are respectively connected to the first The driving part 6 and the second driving part 7 are connected by transmission, specifically: the first driving part 6 and the second driving part 7 are both geared motors, and the second driving part 7 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com