Preparing method of nanotube-nickel-nickel cobalt silicate catalyst

A technology of nanotubes and silicate, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of expensive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

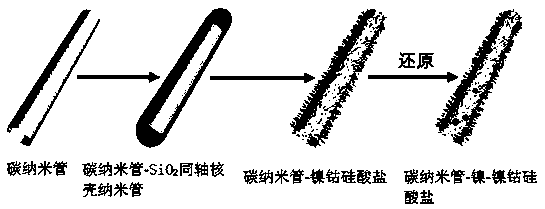

[0026] (1) Disperse carbon nanotubes in ethanol (30mL), water (10mL) and C n TAB (n=10) (30mg) in the mixed solution. After stirring for 30 min, aqueous ammonia (30 mL) was added to adjust the pH to 10. After stirring for 30 min, 10 mL of ethyl orthosilicate was added. After reacting at room temperature for 18 h, it was centrifuged and washed three times with a mixed solution of methanol and water. in a dry box at 100 o C dried for 24h. Get carbon nanotube-SiO 2 Coaxial core-shell nanotubes, SiO 2 The shell thickness is 15nm (eg figure 2 , as shown in 3).

[0027] (2) Take 1g carbon nanotube-SiO 2 , 0.3g nickel nitrate, 0.4g cobalt acetylacetonate, add ammonia water, adjust the pH to 8. Put the mixed solution into the autoclave and heat to 50 o C, after reacting for 24h, cool to room temperature. Centrifuge, wash with methanol, ethanol, and water, and put it into a 100-degree drying oven. Obtain carbon nanotube-nickel cobalt silicate coaxial core-shell nanotubes (...

Embodiment 2

[0031] (1) Disperse carbon nanotubes in ethanol (30mL), water (10mL) and C n TAB (n=10) (30mg) in the mixed solution. After stirring for 30 min, aqueous ammonia (30 mL) was added to adjust the pH to 12. After stirring for 30 min, 10 mL of ethyl orthosilicate was added. After reacting at room temperature for 18 h, it was centrifuged and washed three times with a mixed solution of methanol and water. in a dry box at 100 o C dried for 24h. Get carbon nanotube-SiO 2 Coaxial core-shell nanotubes, SiO 2 The shell thickness is 15nm (eg figure 2 , as shown in 3).

[0032] (2) Take 1g carbon nanotube-SiO 2 , 0.3g nickel nitrate, 0.4g cobalt acetylacetonate, add ammonia water, adjust the pH to 11. Put the mixed solution into the autoclave and heat it to 135 o C, after reacting for 24h, cool to room temperature. Centrifuge, wash with methanol, ethanol, and water, and put it into a 100-degree drying oven. Obtain carbon nanotube-nickel cobalt silicate coaxial core-shell nanotu...

Embodiment 3

[0036] (1) Disperse carbon nanotubes in ethanol (30mL), water (10mL) and C n TAB (n=10) (30mg) in the mixed solution. After stirring for 30 min, aqueous ammonia (30 mL) was added to adjust the pH to 14. After stirring for 30 min, 10 mL of ethyl orthosilicate was added. After reacting at room temperature for 18 h, it was centrifuged and washed three times with a mixed solution of methanol and water. in a dry box at 100 o C dried for 24h. Get carbon nanotube-SiO 2 Coaxial core-shell nanotubes, SiO 2 The shell thickness is 15nm (eg figure 2 , as shown in 3).

[0037] (2) Take 1g carbon nanotube-SiO 2 , 0.3g nickel nitrate, 0.4g cobalt acetylacetonate, add ammonia water, adjust the pH to 13. Put the mixed solution into the autoclave and heat to 220 o C, after reacting for 24h, cool to room temperature. Centrifuge, wash with methanol, ethanol, and water, and put it into a 100-degree drying oven. Obtain carbon nanotube-nickel cobalt silicate coaxial core-shell nanotubes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com