On-site automatic verification system for water quality monitor

A monitor and automatic technology, applied in the field of on-site automatic verification system for water quality monitors, can solve the problems of low efficiency of manual liquid preparation, uncontrollable, high environmental monitoring and governance quality risks, etc., to improve the quality of testing work and reduce quality requirements , the effect of reducing quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

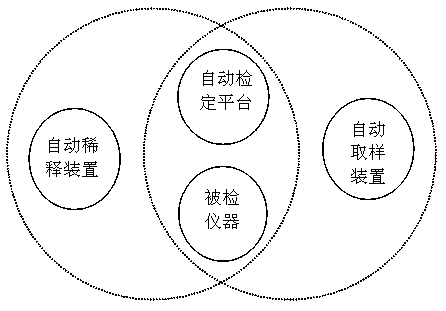

[0059] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings, as shown in the figure, the on-site automatic verification system for water quality monitors of the present invention includes three parts: an on-site automatic verification platform for water quality monitors, an automatic sampling device, and an automatic dilution device; The on-site automatic verification platform of the monitor is installed on a computer with RS485, RS232, Modbus, Modbus TCP and other types of interfaces;

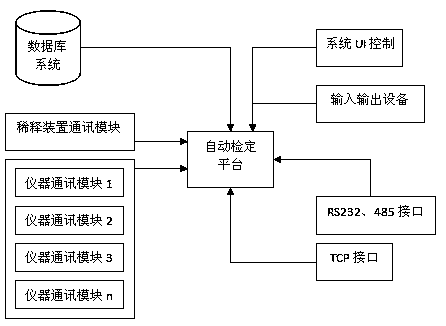

[0060] The system also includes a built-in GPRS communication module connected to the mobile communication network, and the mobile communication network is wirelessly connected to the Internet; the automatic verification platform is respectively connected with a database system, a dilution device communication module, an instrument communication module, a system UI control module, an input Output device, RS485 and RS232 interface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com