Low-chlorine environment-friendly snow melt agent without salt dust and method for preparing low-chlorine environment-friendly snow melt agent

A snow-melting agent and environmental protection technology, applied in the field of snow-melting agent preparation, can solve the problems of easy formation of salt dust, high corrosion and destructiveness of snow-melting agent, secondary pollution of the environment, etc., to achieve the suppression of salt dust formation, good ice-melting effect, and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

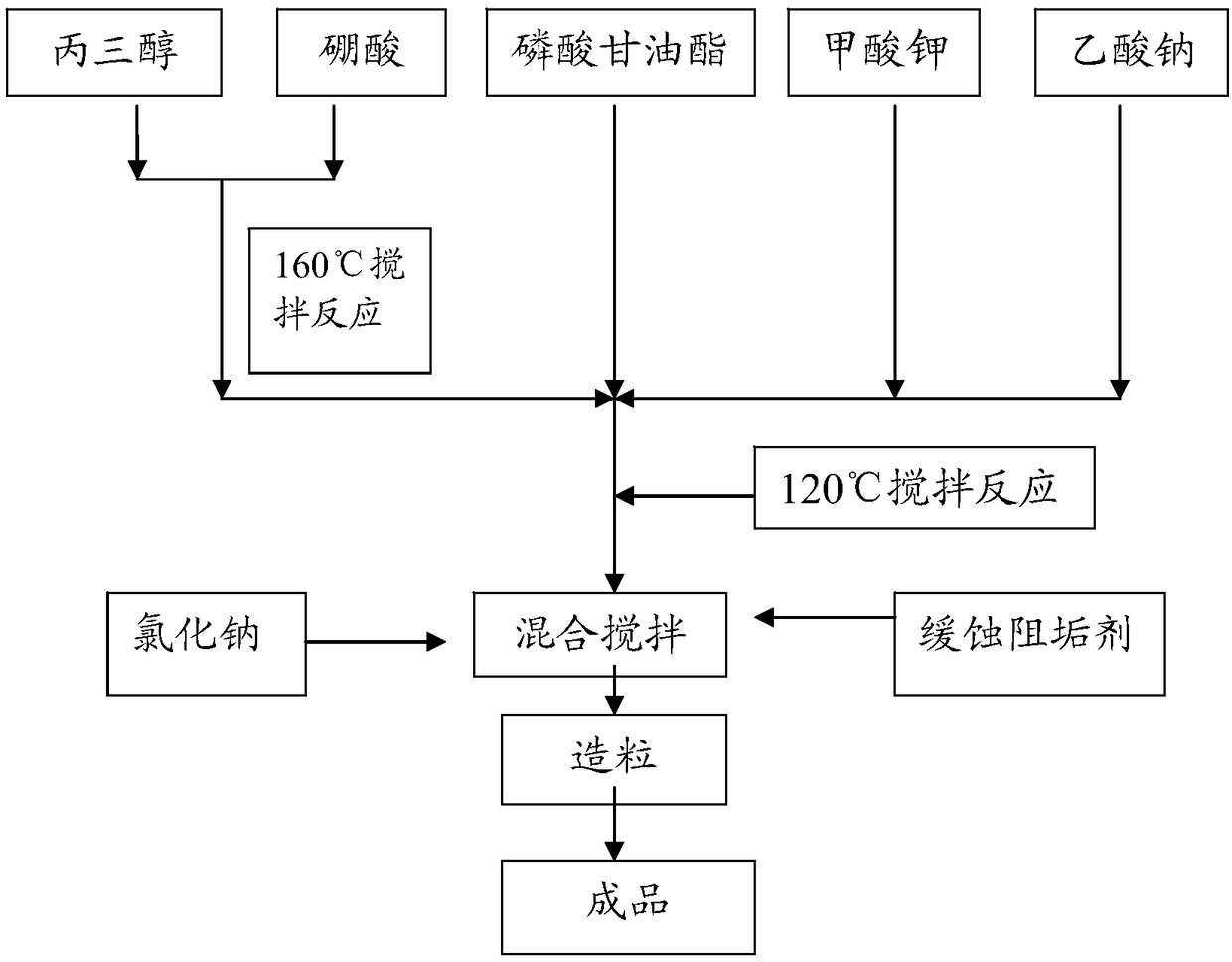

[0026] The technological process of preparation method of the present invention is as figure 1 As shown, specifically, the preparation method includes the following steps: 1). Preparation of anticoagulant: Take 1.56 grams of glycerol and 3 grams of boric acid, mix and heat to 160° C., maintain 160° C. for 1 hour, and keep stirring during the period. The stirring speed is 20 rpm. Take out the reactant, add 1.98 g of phosphoglyceride, 2 g of potassium formate, and 4 g of sodium acetate, mix and heat to 120° C., and keep it for 2 hours; keep stirring during the period, and the stirring speed is 25 rpm;

[0027] 2). Step 1) After the reaction is over, add 85 grams of sodium chloride, 0.5 grams of sodium hexametaphosphate as a slow-release antiscalant, stir evenly, extrude and granulate, and the extrusion pressure is 10 kg, and the finished product is produced. It is yellow-brown granular with a particle size of 0.3-0.6 cm.

Embodiment 2

[0029] This example is carried out on the basis of Example 1, the difference is that the amount of each reagent used is different, see Table 1 for the specific amount.

Embodiment 3

[0031] This example is carried out on the basis of Example 1, the difference is that the amount of each reagent used is different, see Table 1 for the specific amount.

[0032] Table 1. Amounts of reagents used in each example

[0033]

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com