Refining method of N-methyl pyrrolidone product

A technology of methylpyrrolidone and refining method, which is applied in the direction of organic chemistry, can solve the problems of low processing efficiency, complicated operation, low fiber adsorption efficiency, etc., and achieve the effect of reducing light impurity content and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of refining method of N-methylpyrrolidone product, comprises the following steps:

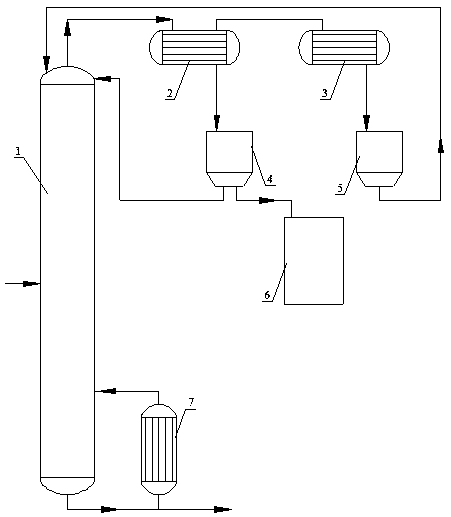

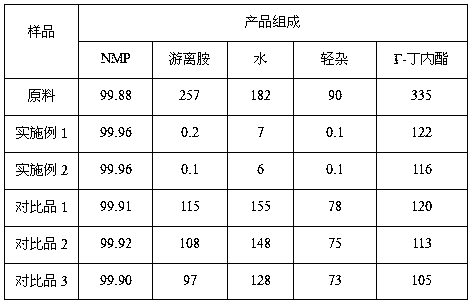

[0026] Such as figure 1 As shown, the N-methylpyrrolidone (raw material) that needs to be purified is sent to the rectification tower 1 for distillation, and the overhead distillate of the rectification tower 1 is sent to the primary heat exchanger 2 for primary condensation. The gas phase product of the first stage condensation is sent to the secondary heat exchanger 3 for secondary condensation, the liquid phase product after the first stage condensation is sent to the first stage reflux tank 4, the gaseous product of the second stage condensation is discharged, and the liquid phase product after the second stage condensation The product is refluxed to the rectification tower 1 through the secondary reflux tank 5, and part of the product in the primary reflux tank 4 is refluxed to the rectification tower 1, and part of it is recovered as N-methylpyrrolidone refined product (into...

Embodiment 2

[0029] A kind of refining method of N-methylpyrrolidone product, comprises the following steps:

[0030]The N-methylpyrrolidone (raw material) that needs to be purified and purified is sent to the rectification tower for distillation, the overhead distillate of the rectification tower is subjected to primary condensation, and the gas phase product after primary condensation is subjected to secondary condensation and primary condensation The final liquid phase product is sent to the primary reflux tank, and the gas phase product after the secondary condensing is discharged, the liquid phase product after the secondary condensing is refluxed to the rectification tower through the secondary reflux tank, and the product in the primary reflux tank is partially refluxed To the rectification tower, and at the same time, part of it is recovered as a refined product of N-methylpyrrolidone; the bottom of the rectification tower is connected with a reboiler.

[0031] Among them, the pres...

Embodiment 3

[0033] A kind of refining method of N-methylpyrrolidone product, comprises the following steps:

[0034] The N-methylpyrrolidone (raw material) that needs to be purified and purified is sent to the rectification tower for distillation, the overhead distillate of the rectification tower is subjected to primary condensation, and the gas phase product after primary condensation is subjected to secondary condensation and primary condensation The final liquid phase product is sent to the primary reflux tank, and the gas phase product after the secondary condensing is discharged, the liquid phase product after the secondary condensing is refluxed to the rectification tower through the secondary reflux tank, and the product in the primary reflux tank is partially refluxed To the rectification tower, and at the same time, part of it is recovered as a refined product of N-methylpyrrolidone; the bottom of the rectification tower is connected with a reboiler.

[0035] Among them, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com