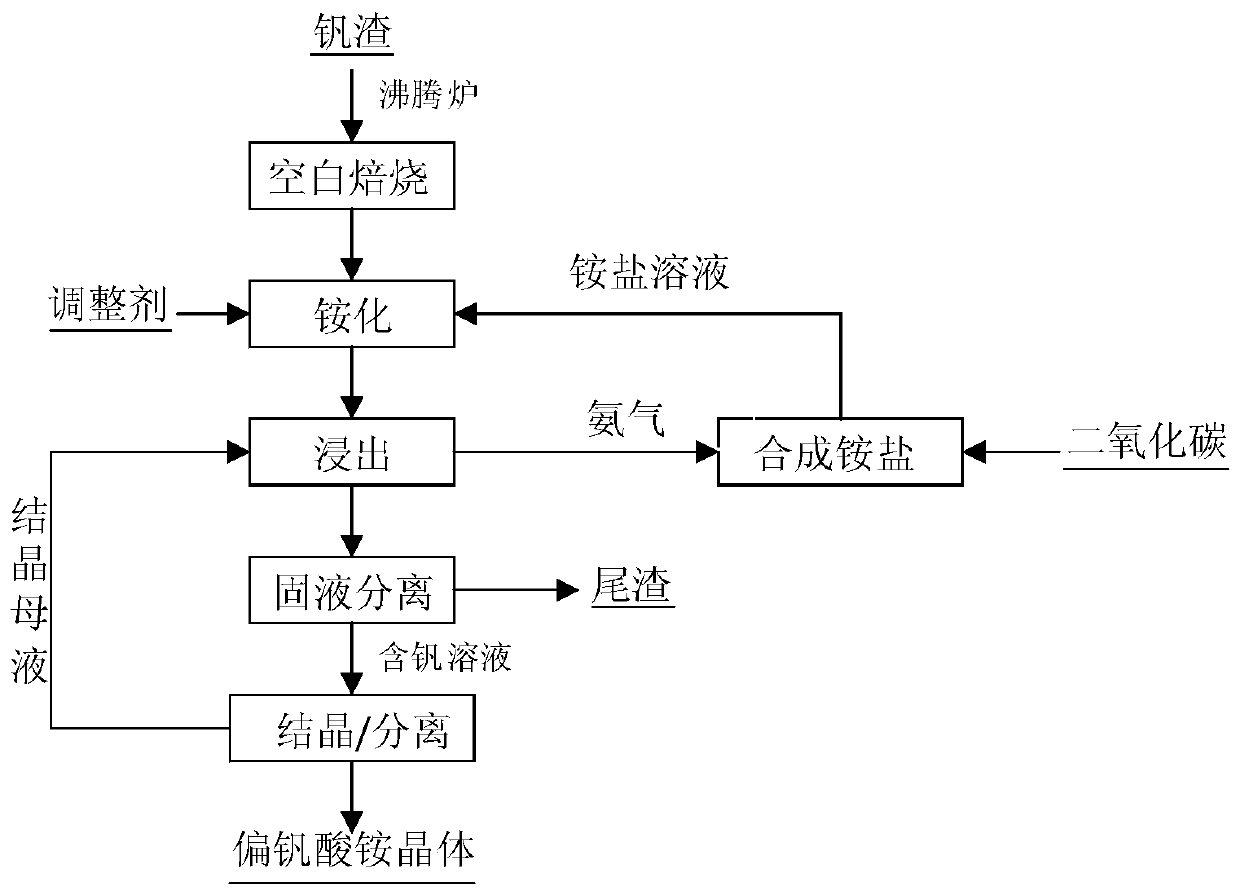

A method for extracting vanadium by ammonification of vanadium slag blank roasting

A blank roasting and vanadium slag technology is applied in the field of vanadium chemical industry and metallurgy to achieve the effects of reducing production costs, improving solid-liquid separation performance, and increasing vanadium conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Add 1 kg of vanadium slag with a particle size of 100-200 mesh into the fluidized fluidized furnace, and control the blast volume of the fluidized fluidized furnace to 4Nm 3 / h (under standard conditions), the air flow rate is 1.0m / s, and the temperature is raised to 900°C for blank roasting for 0.4h, and the roasted clinker is naturally cooled in the air;

[0053] (2) add ammonium bicarbonate solution in the roasting clinker that step (1) obtains and carry out ammonization, add the sodium carbonate regulator of vanadium slag quality 3% simultaneously, the concentration of control ammonium bicarbonate solution is 50wt%, and temperature is 50 ℃, the liquid-solid ratio of solution and roasted clinker is 0.4:1, and the ammonization time is 3h;

[0054] (3) After the ammonization reaction is completed, add hot liquid to the mixed material for leaching, and leaching at 90°C for 3 hours. The ammonia gas and carbon dioxide generated during leaching will synthesize ammonium...

Embodiment 2

[0058] (1) Add 0.1kg of vanadium slag with a particle size of 150-200 mesh into the fluidized fluidized furnace, and control the blast volume of the fluidized fluidized furnace to 1Nm 3 / h (under standard conditions), the air flow rate is 1.8m / s, and the temperature is raised to 800°C for blank roasting for 0.45h, and the roasted clinker is naturally cooled in the air;

[0059] (2) add ammonium bicarbonate solution in the roasting clinker that step (1) obtains and carry out ammonization, add the sodium carbonate regulator of vanadium slag quality 2% simultaneously, the concentration of control ammonium bicarbonate solution is 30wt%, and temperature is 40 ℃, the liquid-solid ratio of solution and roasted clinker is 0.4:1, and the ammonization time is 1h;

[0060] (3) After the ammonization reaction is completed, add hot liquid to the mixed material for leaching, and leaching at 80°C for 2.5 hours. The ammonia gas and carbon dioxide generated during leaching will synthesize ammo...

Embodiment 3

[0064] (1) Add 0.5kg of vanadium slag with a particle size of 100-150 mesh into the fluidized fluidized furnace, and control the blast volume of the fluidized fluidized furnace to 2Nm 3 / h (under standard conditions), the air flow rate is 0.8m / s, and the temperature is raised to 950°C for blank roasting for 0.2h, and the roasted clinker is naturally cooled in the air;

[0065] (2) add ammonium bicarbonate solution in the roasting clinker that step (1) obtains and carry out ammonization, add the sodium carbonate regulator of vanadium slag quality 5% simultaneously, the concentration of control ammonium bicarbonate solution is 45wt%, and temperature is 60 ℃, the liquid-solid ratio of solution and roasted clinker is 0.2:1, and the ammonization time is 1h;

[0066] (3) After the ammonization reaction is completed, add hot liquid to the mixed material for leaching, and leaching at 90°C for 1 hour. The ammonia gas and carbon dioxide generated during leaching will synthesize ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com