A kind of tooling for turning and processing the back cover shell

A turning and shell technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low processing efficiency, complex processing process, and difficult to ensure position accuracy, so as to improve accuracy and ensure mutual position. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

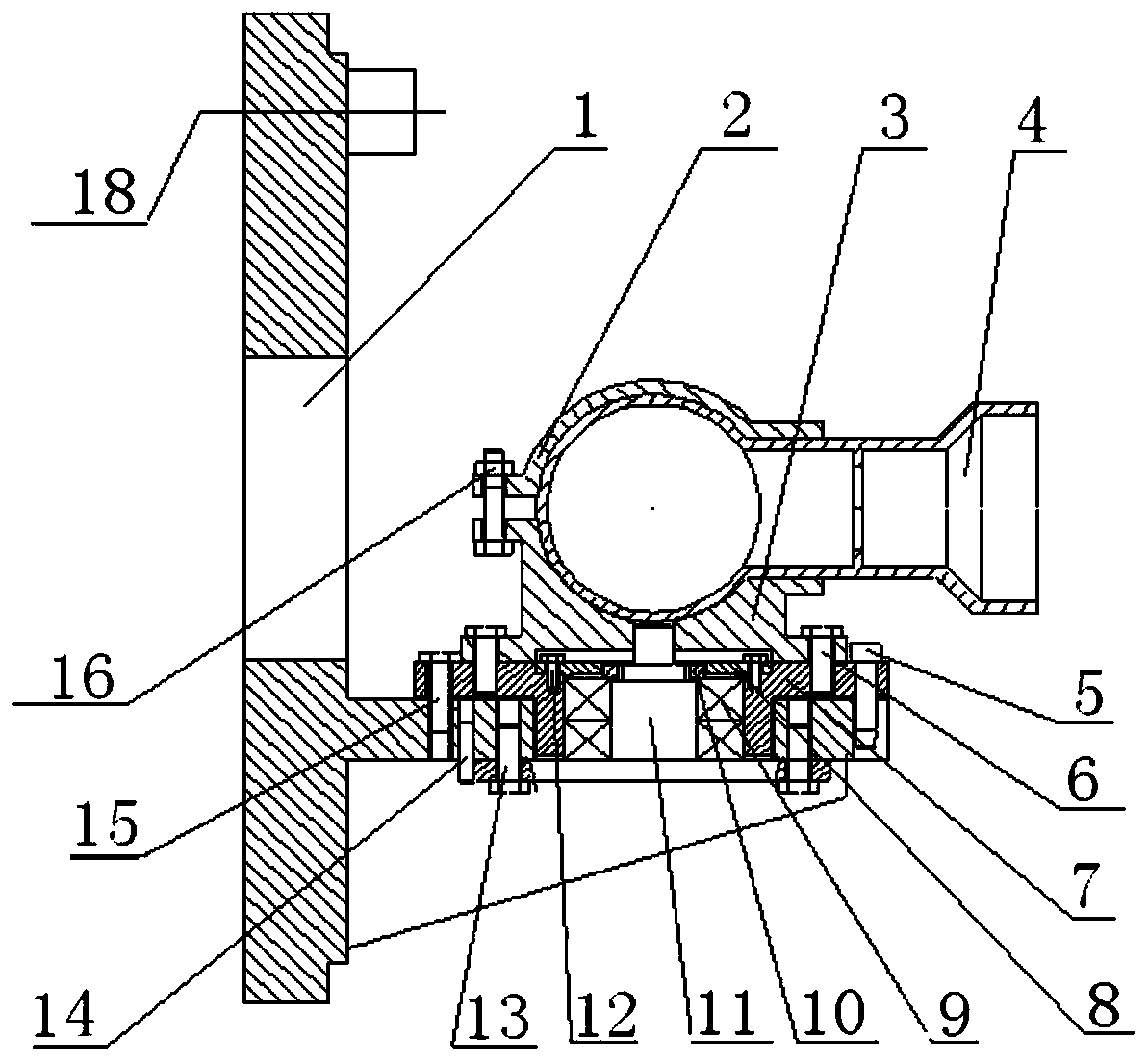

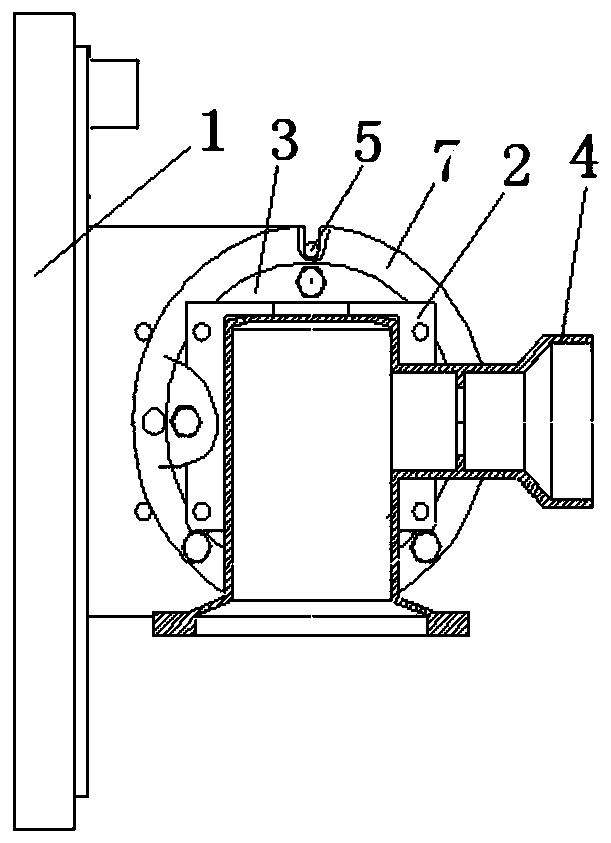

[0029] This embodiment is a tool for turning the back cover shell. The rear cover shell is composed of two cylinders perpendicular to each other on the same plane, wherein the larger cylinder is the first cylinder, and the other cylinder is the second cylinder.

[0030] This embodiment includes turning device body 1, workpiece clamping gland 2, workpiece clamping seat 3, rotating index plate 7, bearing gland 8, single row tapered roller bearing 9, bearing compression nut 10, shaft 11, bearing Gland connecting bolt 12, bearing seat connecting bolt 13, positioning pin 14, rotating index plate fixing bolt 15, workpiece clamping bolt 16 and counterweight 18.

[0031] Wherein, the rotating index plate 7 is installed on the upper surface of the mounting plate of the turning device body 1, and is fixed on the upper surface of the mounting plate of the turning device body 1 with bolts during turning, and the inner surface of the rotating index plate 7 The hole is installed on the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com