Fixture for drilling differential lock pressure switch holes and ventilation hole inclined holes of intermediate and rear axle housing assemblies of automobile

A technology for pressure switches and rear axle housings, applied in clamping, manufacturing tools, and drilling molds for workpieces, etc., can solve the problems of high processing costs and low efficiency, and achieve low manufacturing costs, extended positioning length, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

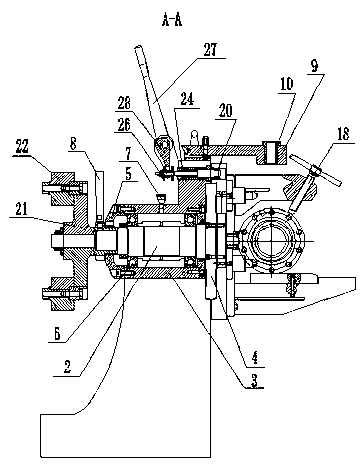

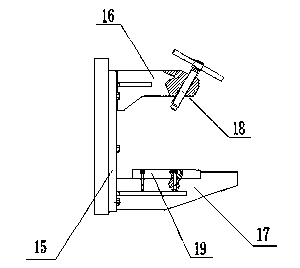

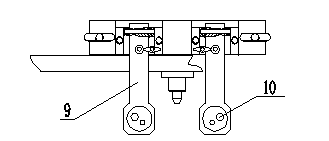

[0023] See figure 1 , figure 2 , the drilling jig for the differential lock pressure switch hole and air hole oblique hole of the rear axle housing assembly in the automobile, including an organic base 1, an outer shell arranged on the top of the machine base 1, a main shaft 2 arranged in the outer shell, and a main shaft 2 arranged on the main shaft 2. The handle 8 used to rotate the main shaft 2 and the rotating plate assembly and the rotating counterweight mechanism connected with the main shaft 2 for fixing the middle and rear axle housing assembly; see Figure 4 , the top of the middle part of the machine base 1 is provided with two eccentric drill sleeve type drill formwork assemblies, the two eccentric drill sleeve type drill formwork assemblies include the eccentric drill sleeve type drill template 9 and the clamping slot arranged in the eccentric drill sleeve type drill template 9 The inner jig cover 10; the outer shell includes a transparent cover 3, a front cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com