Detection method for reactor of fluid-bed

A fluidized bed reactor and detection method technology, applied in chemical instruments and methods, liquid/fluid solid measurement, instruments, etc., can solve the problems of difficult installation of capacitance monitoring, large temperature monitoring error, time insensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In a gas-solid fluidized bed made of plexiglass with a height of 1000mm and an inner diameter of 150mm, the distribution plate is a porous plate with a hole diameter of 2.0mm and an opening rate of 2.6%. Air is used as the fluidizing gas and the superficial gas velocity is 0.6m / s, the height of the static bed is 500mm, and the passive acoustic emission transducer is attached to the top of the distribution plate at 20mm, 50mm, 100mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, 450mm, 500mm, 550mm, 600mm, 650mm, At 700mm, 750mm, 800mm, 850mm, 900mm, 950mm, 970mm, 1000mm, 1050mm, 1100mm, the sampling frequency is 500kHz, and the sampling time is 10s each time.

[0039] Keeping the fluidization state of the particles in the fluidized bed and other experimental conditions unchanged, several passive acoustic emission transducers at different positions on the wall of the fluidized bed are used to detect the acoustic wave signal of the linear low-density polyethylene particles co...

Embodiment 2

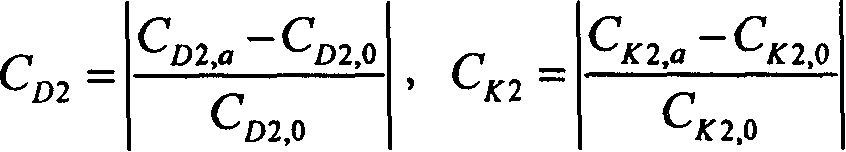

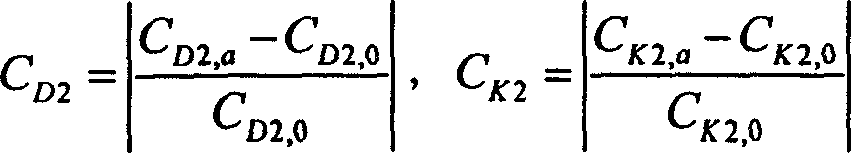

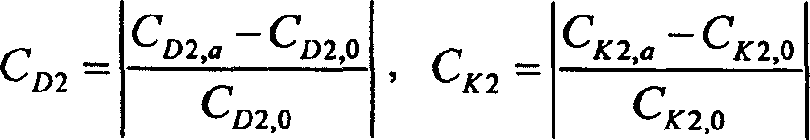

[0043] A passive acoustic emission transducer is installed on the wall above the gas distribution plate of the fluidized bed reactor, and the signal received by it is collected after A / D conversion. The sampling frequency is 500kHz, and each sampling time is 10s. Calculate the collected acoustic signal to find the correlation dimension C in the chaotic characteristic parameters of the acoustic signal D2,a and K entropy C K2,a And the correlation dimension C of the acoustic signal in the normal state D2,0 and K entropy C K2,0 , and calculate the failure coefficient of particle agglomeration according to the following formula:

[0044] C D 2 = | C D 2 , a - C D 2,0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com