Optical phase put-off precision measurement method and system thereof

A precision measurement, optical phase technology, applied in the field of optical measurement, can solve the problems of low measurement accuracy, high installation and adjustment requirements, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

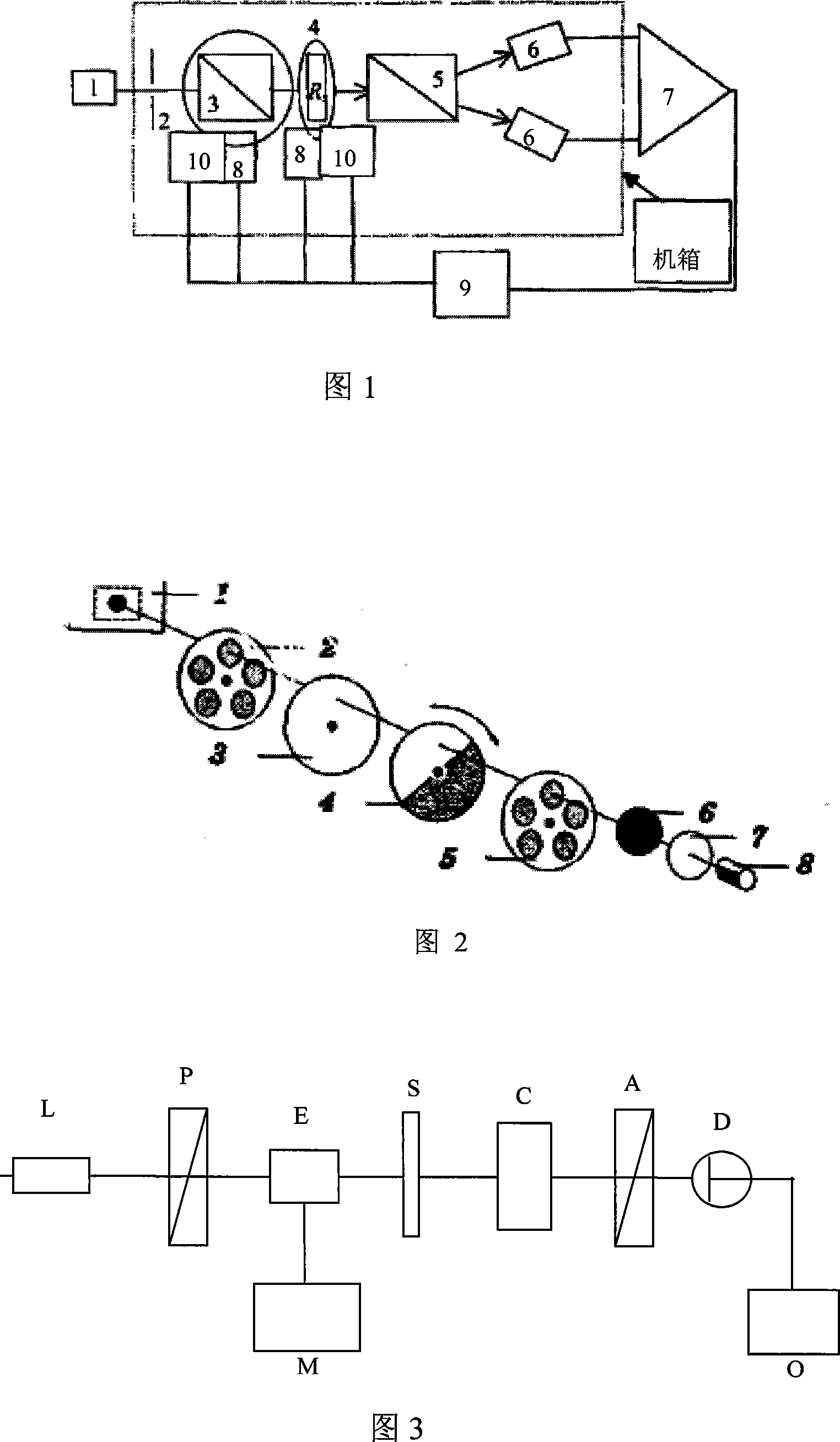

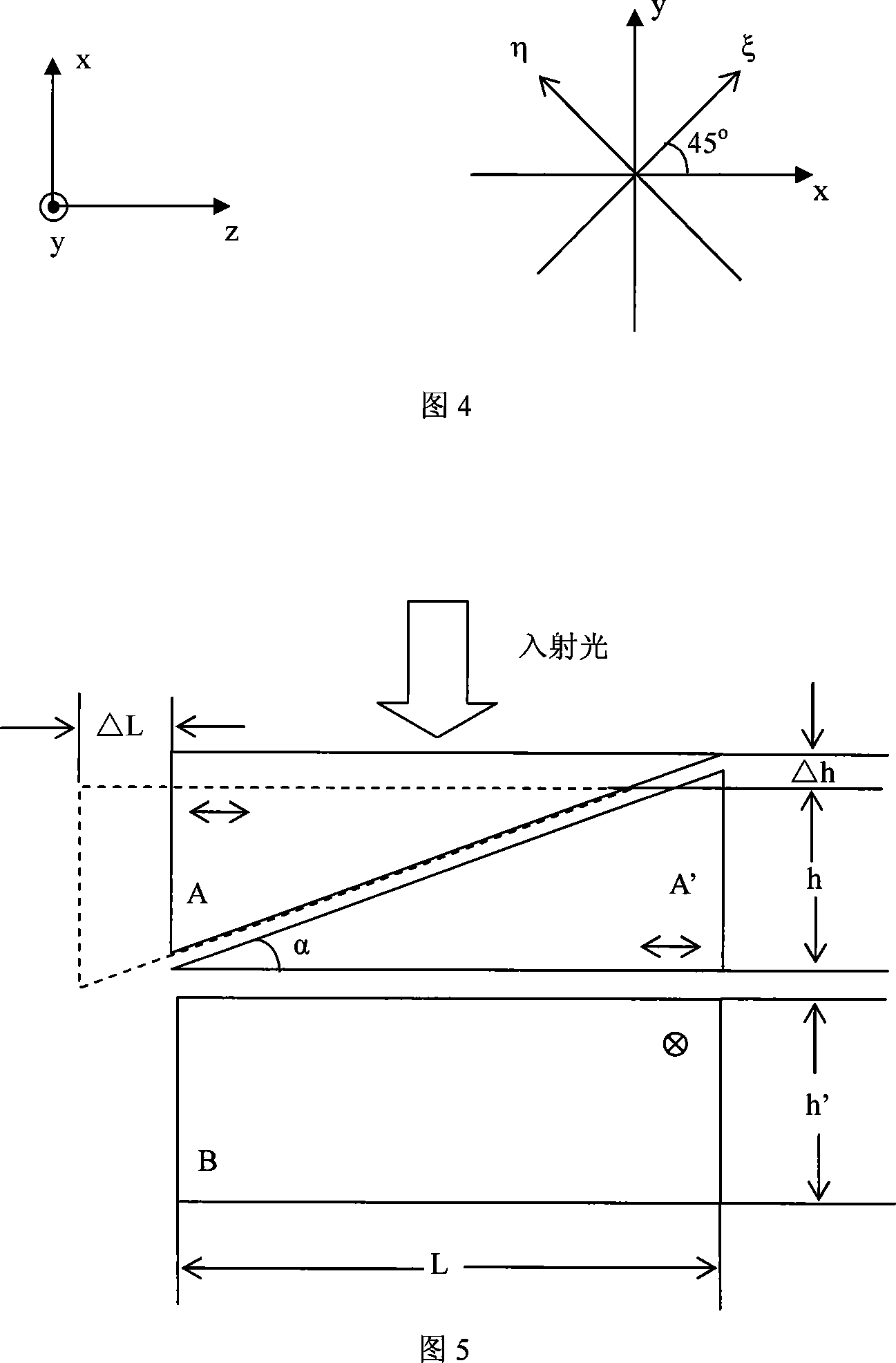

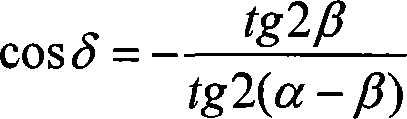

[0056] Specific embodiments of the present invention will now be described in conjunction with the accompanying drawings. The device used in Figure 3 is: the laser L can be a He-Ne laser with a wavelength of 632.8nm and a power of 2mw. Polarizer P and analyzer A can use extinction ratio of 10 5 , Glan-Taylor polarizing prism with aperture>10mm. The optical modulator E can use the KD*P crystal longitudinal modulation method as the modulator. The modulation signal is a sinusoidal voltage, the voltage adjustment range is: 600-2000V, and the modulation frequency is: 2kHz. The Soleil compensator C can be made of quartz material, the working wavelength range is 200-2000nm, the horizontal movement range of the optical wedge is 0-30mm, the movement accuracy is 1μm, and the optical aperture is above 10mm. The light detector D can use a photodiode for photoelectric conversion and detection. A matching signal processing circuit is designed according to the modulation frequency, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com