Slant lathe bed planing and grinding general clamp

A technology of inclined bed and fixture, applied in clamping, planer, milling machine and other directions, can solve the problems of high cultural and technical level requirements of operators and troublesome calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in combination with specific embodiments.

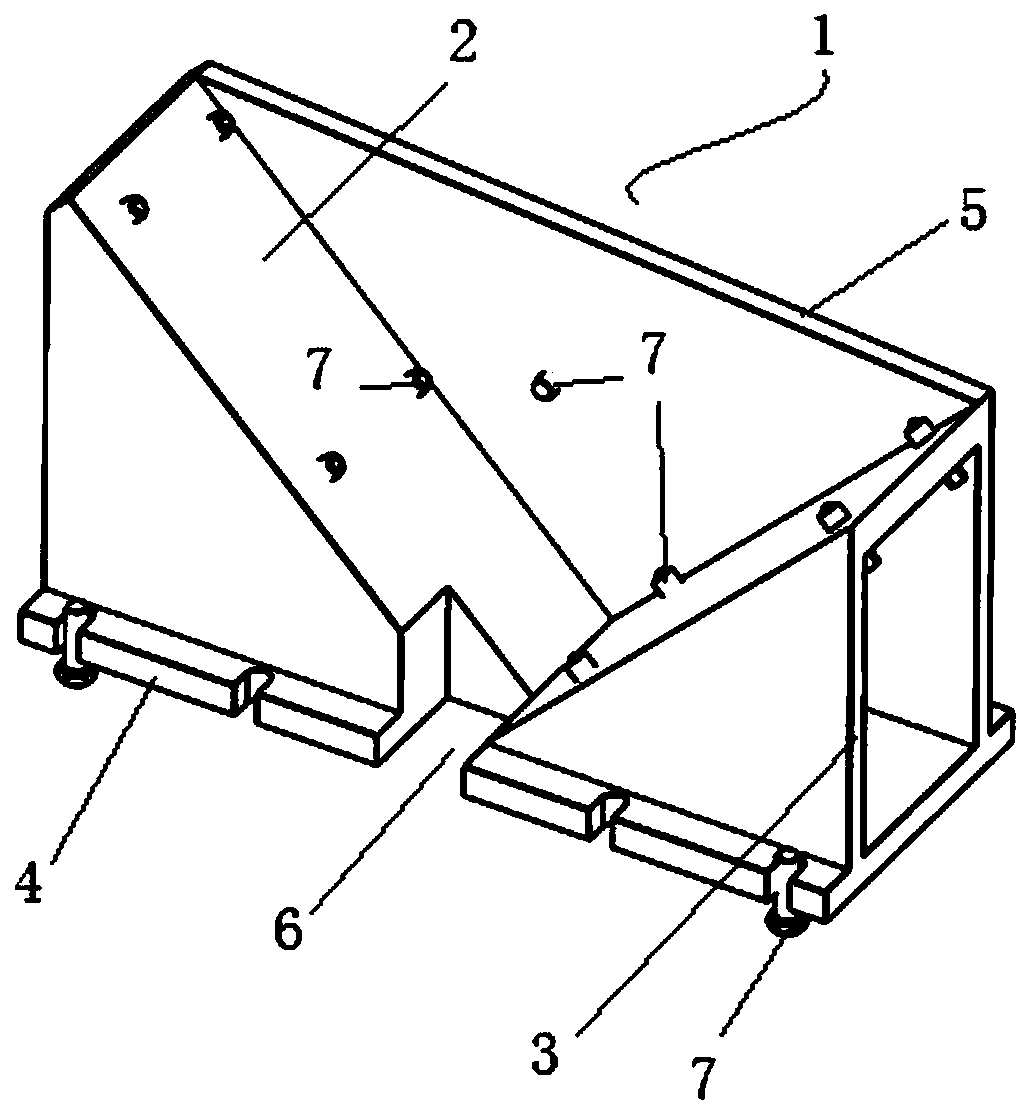

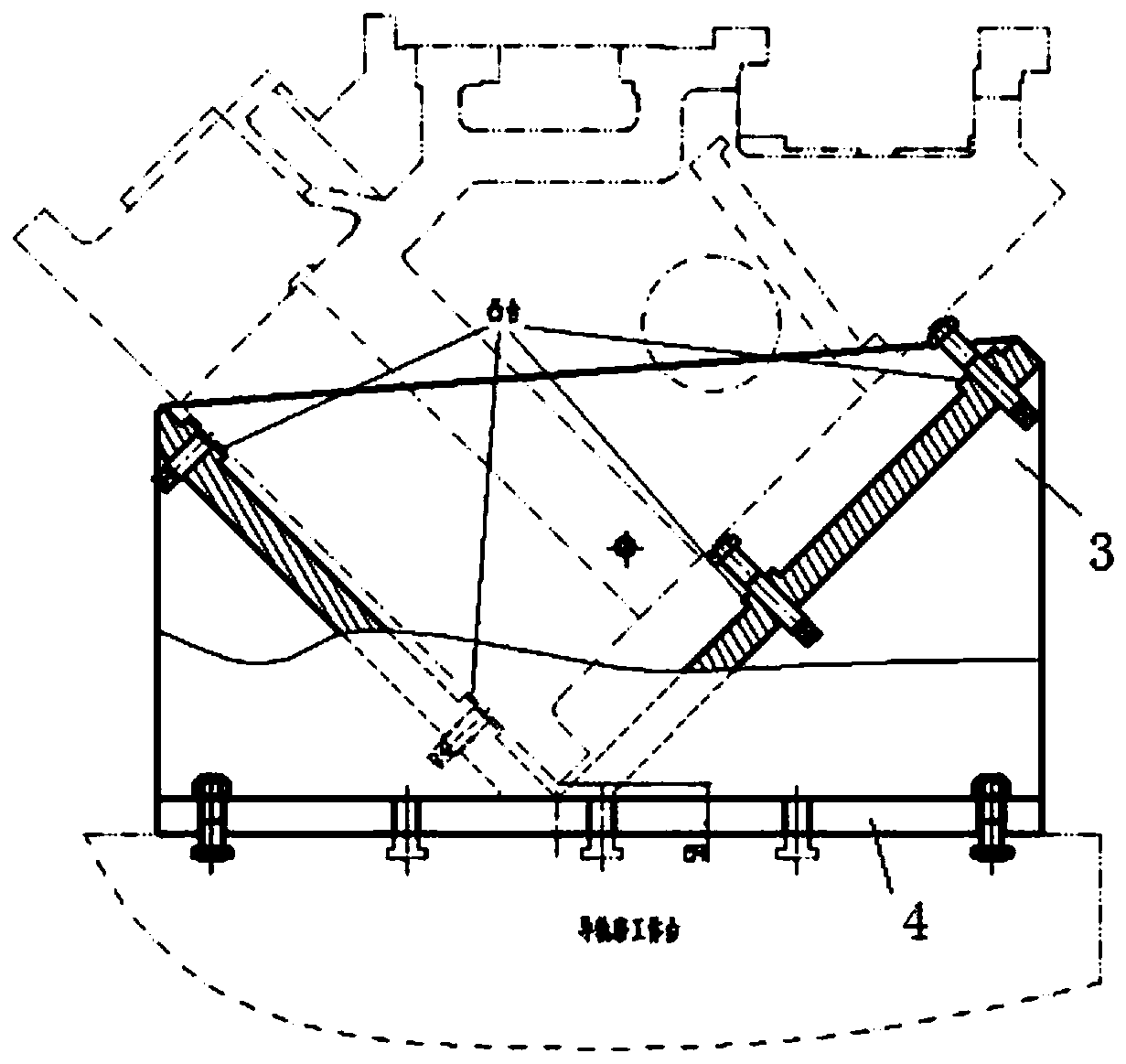

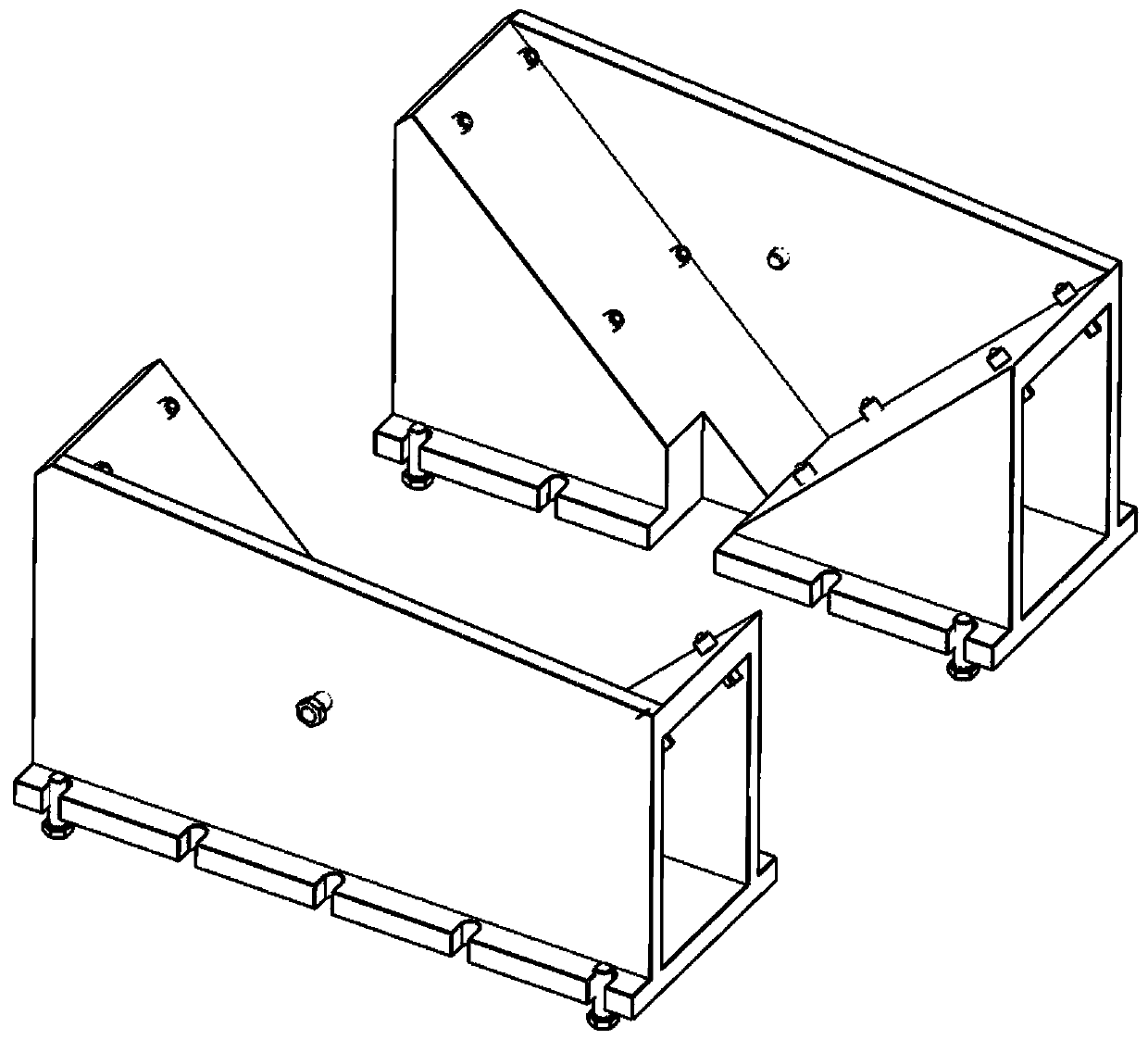

[0010] The universal clamp for planing and grinding of the inclined bed of the present invention is as follows: figure 1 and figure 2 As shown, it includes a universal jig body 1 for planing and grinding with inclined bed. There are two inclined support surfaces 2 at an angle of 45° with the bottom plate 4 on the universal jig body 1 for planing and grinding with inclined bed. The bottom surface of the shell 3 is a part of the bottom plate 4. One of the sides of the housing 3 is a part of the side plate 5, a U-shaped groove 6 is opened on the bottom plate 4, the U-shaped groove 6 runs through the bottom of the housing 3, and the housing 3, the bottom plate 4, and the side plate 5 are all A screw 7 is provided for connecting the workbench and clamping the workpiece. The screw 7 on the base plays the role of pressing and fixing the clamp body on the workbench of the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com