Grinding and collecting device and method for grinding and collecting materials by using same

A collection device and collection unit technology, which is applied in the field of grinding collection materials and grinding collection devices, can solve the problems of material flying out of the container, reduce work efficiency, reduce time, etc., achieve uniform powder particle size, improve work efficiency, and flexibly dismantle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

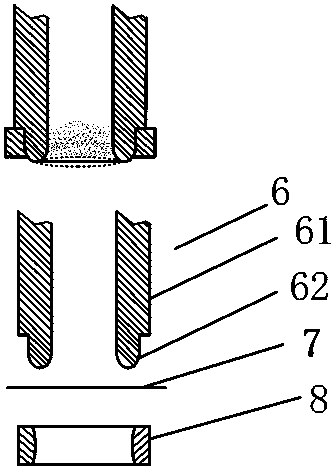

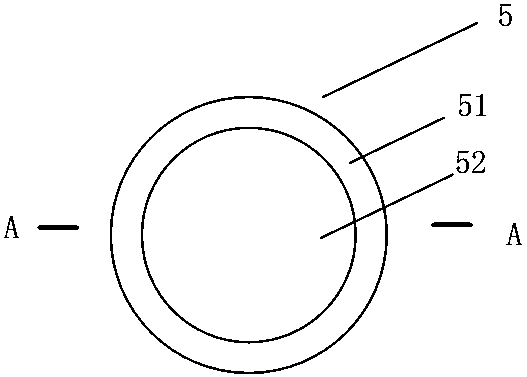

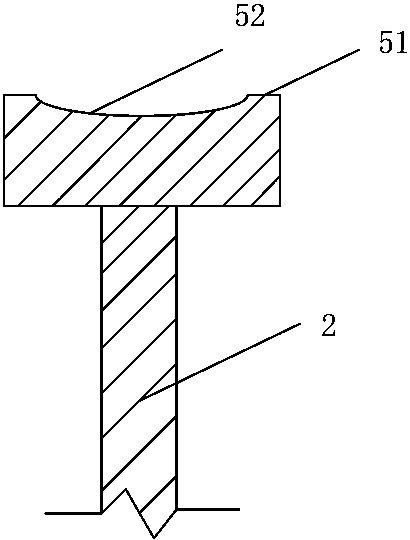

[0028] A grinding and collecting device, comprising a grinding part, a collecting part and a base part 9, combined with the instructions attached figure 1 and 2 , the grinding part includes a circular handle part 1, a rod part 2, a cover part 3, a barrel part 4 and a squeeze part 5, a base part 9 is detachably mounted on the bottom of the grinding part, and a collecting part includes a filter conduit 6, a screen 7, a buckle The tight ring 8 and the storage part 10; the base part 9 is detachably installed at the bottom of the grinding part, and the collection part is built into the base part 9, due to the proportion, figure 1 The filter conduit 6, screen cloth 7 and fastening ring 8 of the collecting part are not shown in the drawing, figure 2 for figure 1 The detailed enlarged view of the corresponding positions of the above three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com