Metal-free H2S selective catalytic oxidation catalyst and preparation method thereof

A catalytic oxidation and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of low cost, rich pore structure, and multi-channel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

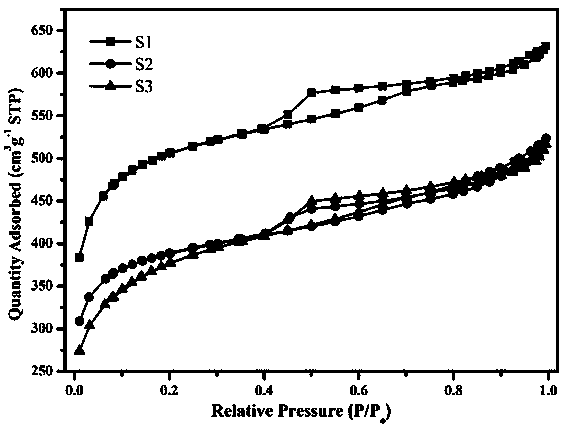

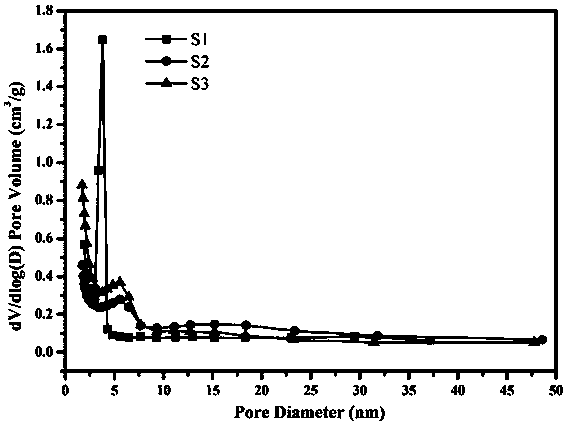

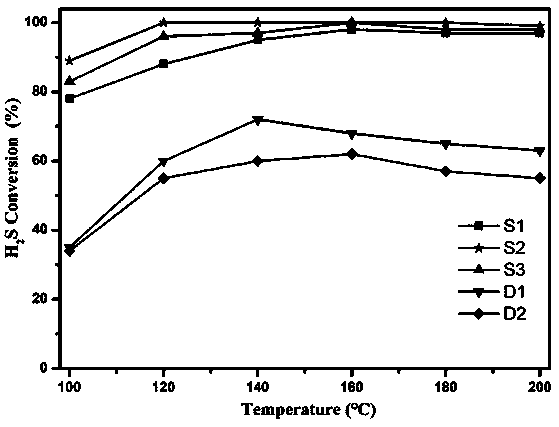

[0033] Take an appropriate amount of glucose in a mortar, grind for 15-30 minutes, sieve with a standard sieve to obtain glucose below 120 mesh, and record it as raw material A; take an appropriate amount of melamine in a mortar, grind for 15-30 minutes, and use Standard sieve sieves and obtains 120 mesh melamine, which is recorded as raw material B. Take by weighing raw material A with an analytical balance to be 1g, take by weighing raw material B to be 35g, raw material A and B are fully mixed in the mortar by the mass ratio of 1:35, then the mixed mixture is packed in the ball mill jar of 100ml, Put the agate grinding balls into the ball milling tank according to the mass ratio of large balls accounting for 20%, medium balls accounting for 50% and small balls accounting for 30%. At the speed of 230 rpm, grind clockwise for 30 minutes, then press counterclockwise Orientation ball mill for 30 minutes. After the ball milling is over, put the mixture in the ball mill jar into...

Embodiment 2

[0034] Embodiment 2 (best embodiment):

[0035] Take an appropriate amount of chitosan in a mortar, grind for 15-30 minutes, and sieve with a standard sieve to obtain chitosan below 120 mesh, which is recorded as raw material A; take an appropriate amount of dicyandiamide in a mortar, grind After 15 to 30 minutes, sieve with a standard sieve to obtain 130 mesh dicyandiamide, which is recorded as raw material B. Take by weighing raw material A with an analytical balance to be 1g, take by weighing raw material B to be 35g, raw material A and B are fully mixed in the mortar by the mass ratio of 1:35, then the mixed mixture is packed in the ball mill jar of 100ml, Put the agate grinding balls into the ball milling tank according to the mass ratio of large balls accounting for 20%, medium balls accounting for 50% and small balls accounting for 30%. At the speed of 230 rpm, grind clockwise for 40 minutes, then press counterclockwise Orientation ball mill for 40 minutes. After the ...

Embodiment 3

[0037] Take an appropriate amount of sucrose in a mortar, grind for 15 to 30 minutes, sieve with a standard sieve to obtain sucrose below 120 mesh, and record it as raw material A; take an appropriate amount of urea in a mortar, grind for 15 to 30 minutes, and use Standard sieve sieves to obtain 140 mesh urea, which is recorded as raw material B. Take by weighing raw material A with an analytical balance to be 1g, take by weighing raw material B to be 35g, raw material A and B are fully mixed in the mortar by the mass ratio of 1:35, then the mixed mixture is packed in the ball mill jar of 100ml, Put the agate grinding balls into the ball mill jar according to the mass ratio of large balls accounting for 20%, medium balls accounting for 50% and small balls accounting for 30%. At the speed of 230 rpm, grind clockwise for 50 minutes, then press counterclockwise Orientation ball mill for 50 minutes. After the ball milling is over, put the mixture in the ball mill jar into a ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com