Method for preparing dendritic Pt-Ni-Cu alloy nano-particles

A technology of alloy nanoparticles and alloy nanoparticles, which is applied in nanotechnology, nanotechnology, metal processing equipment and other directions, can solve the problems of easy poisoning, short life and high price of Pt nanostructured catalysts, and achieve excellent electrochemical activity and activity. The effect of high bit density and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

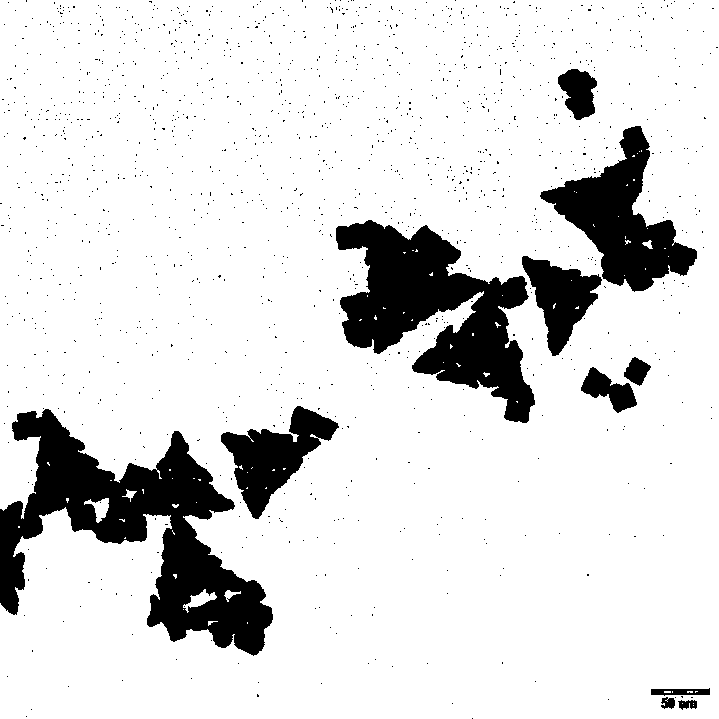

[0023] Measure 2.0mL of chloroplatinic acid aqueous solution with a concentration of 20mmol / L, 1.0mL of copper chloride aqueous solution with a concentration of 20mmol / L and 1.0mL of nickel chloride aqueous solution with a concentration of 20mmol / L in a beaker, then add glycine, polyethylene Pyrrolidone K30 and NaBr, then add methanol, stir with a magnetic stirrer for 12 hours to make it fully coordinated, then transfer it to a reaction kettle, place it in an oven and heat it for reaction, after the reaction is completed, it will undergo centrifugal washing with water and ethanol, and freeze drying step, to obtain dendritic Pt-Ni-Cu alloy nanoparticles (such as figure 2 shown), wherein the dosage range of glycine is 303mg, the dosage range of polyvinylpyrrolidone K30 is 200mg, the dosage range of NaBr is 600mg, and the dosage range of methanol is 0.7mL.

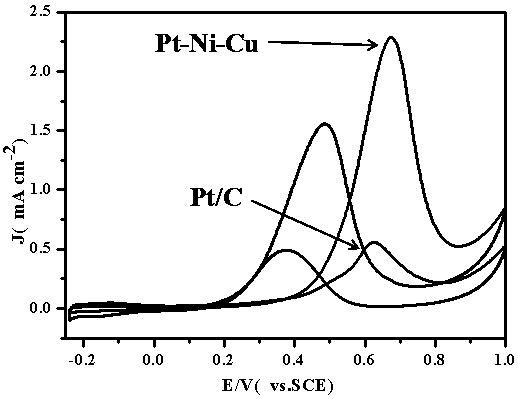

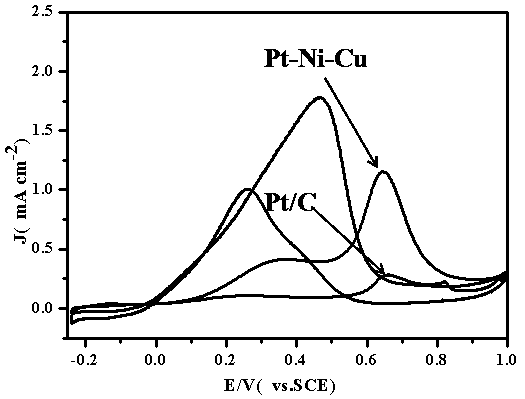

[0024] Methanol (formic acid) electro-oxidation test: The anode electro-oxidation performance test is carried out on a CHI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com