Large strain based macromoleclar polymer concrete fatigue life evaluation method

A high-molecular polymer and fatigue life technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the fatigue life of asphalt materials, which cannot meet the requirements of high-molecular polymer concrete, and does not involve the fatigue life of high-molecular polymer concrete. evaluation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for evaluating the fatigue life of polymer concrete based on large strains, comprising the following steps:

[0053] Step 1: Design the mix ratio of the polymer mixture;

[0054] Step 2: Determine aggregate crushed stone, polymer binder glue-stone ratio;

[0055] Step 3: Take aggregate gravel and polymer binder and mix according to the mixing ratio, form a test piece, and conduct a split test to determine its curing age;

[0056] Step 4: According to the determined gradation and rubber-stone ratio, use the wheel to form the rutting test plate;

[0057] Step 5: After the curing time is reached, cut it into a beam-type test piece;

[0058] Step 6: Perform a four-point loading trabecular fatigue test on the formed specimen.

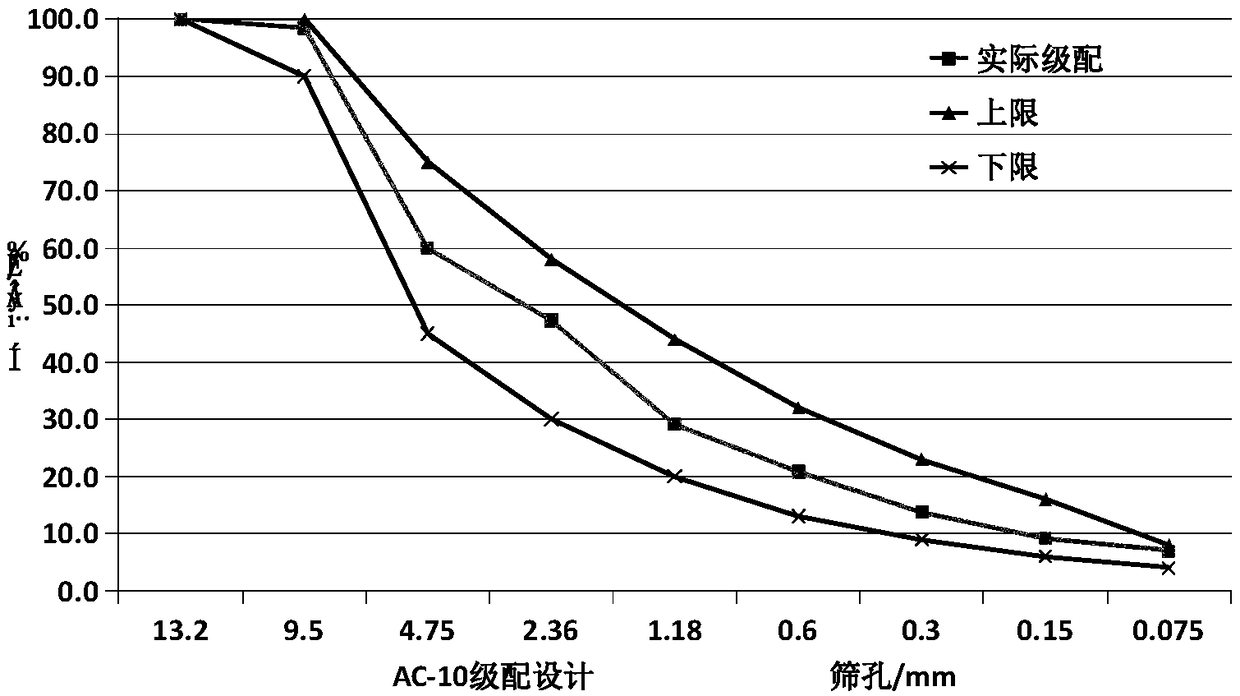

[0059] The thickness of the bridge deck pavement used in this experiment is 2-5cm. According to the "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004) about the relationship between the thickness of the asph...

Embodiment 2

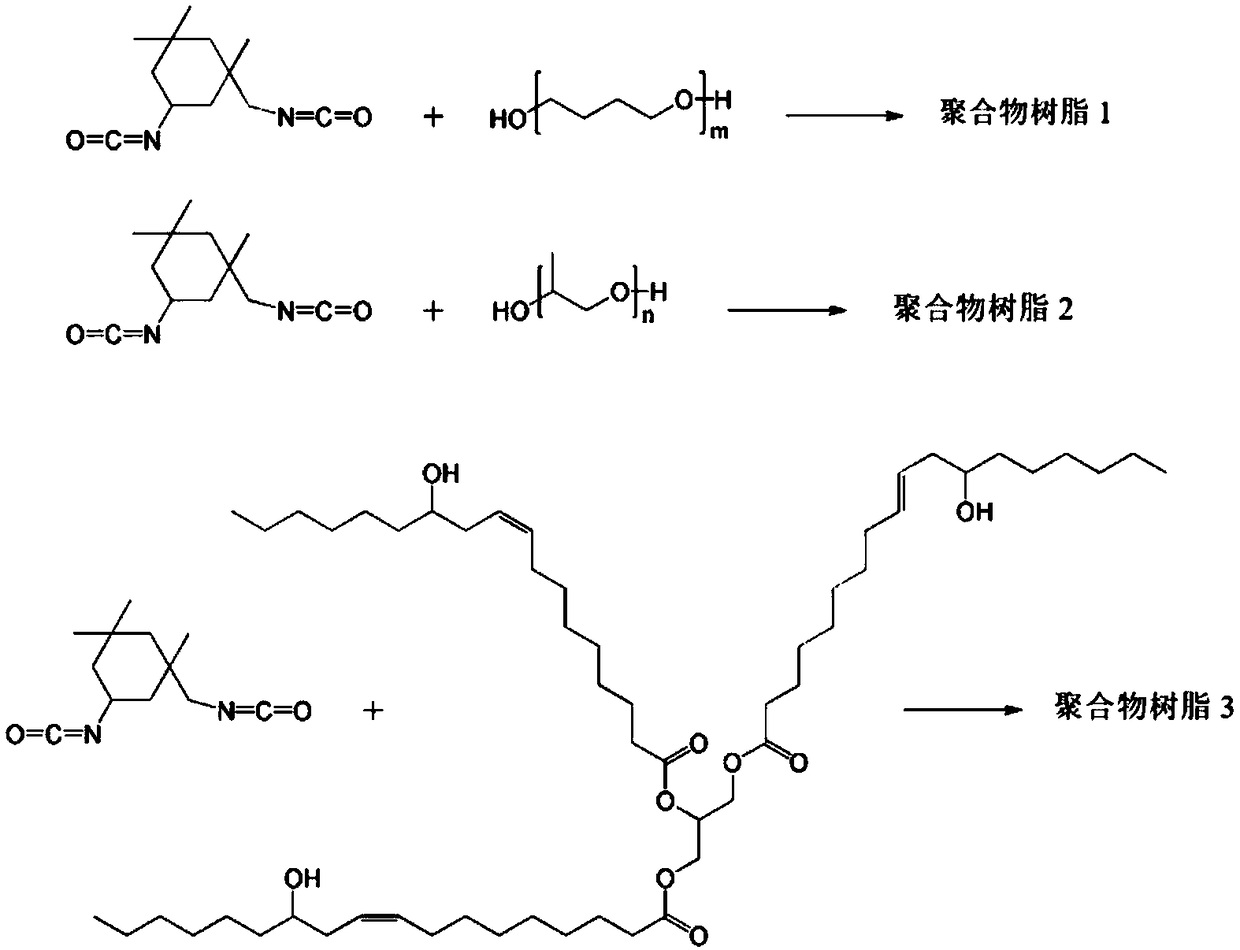

[0077] Different from Example 1, the polymer in the present invention is mainly synthesized from polyol and isocyanate. The -NCO group in the polymer resin cementing material forms a better network hinge structure after curing, which can form better hardness and strength. Its main components are polyol and isocyanate. The ratio of polyol to isocyanate during synthesis is 1:3. The mixing reaction time during synthesis is 10-15 minutes. The humidity in the air needs to be controlled during synthesis. The humidity is not more than 40%, and the relative humidity is not more than 70%. The specific synthetic route of high molecular polymer is as follows: image 3 shown.

Embodiment 3

[0079] The difference from Example 2 is that the ratio of the amount added during synthesis is polyol:isocyanate is 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com