Splicing method and structure for new and old roads in reconstruction and extension of pavement

A technology in the construction of new and old roads, applied to roads, roads, buildings, etc., can solve the problems that affect the overall project quality of the reconstruction and expansion of roads, poor shear and bending resistance, uneven settlement of the road surface, etc. Anti-shear and bending resistance, strong bearing capacity and durability, improved bearing capacity and durability, simple and feasible method and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation plan

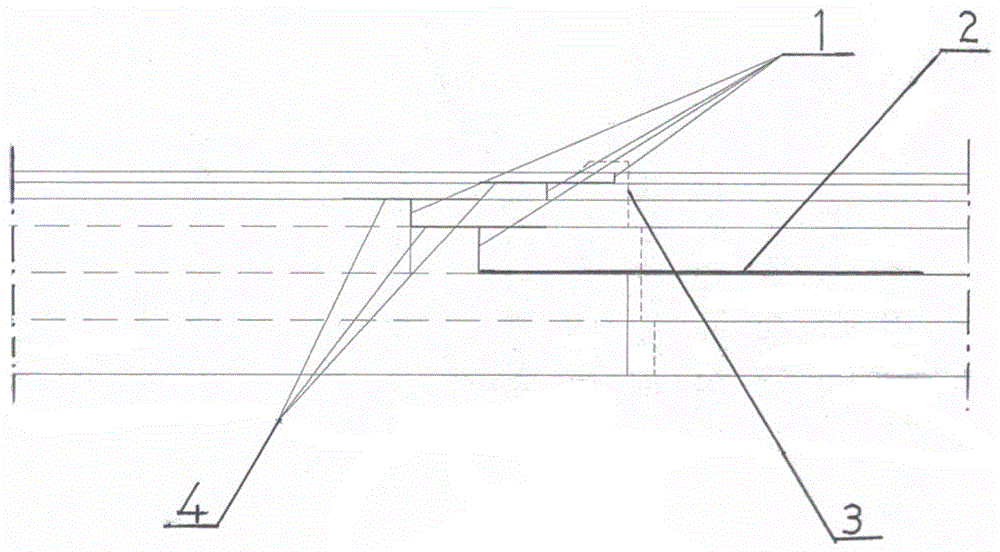

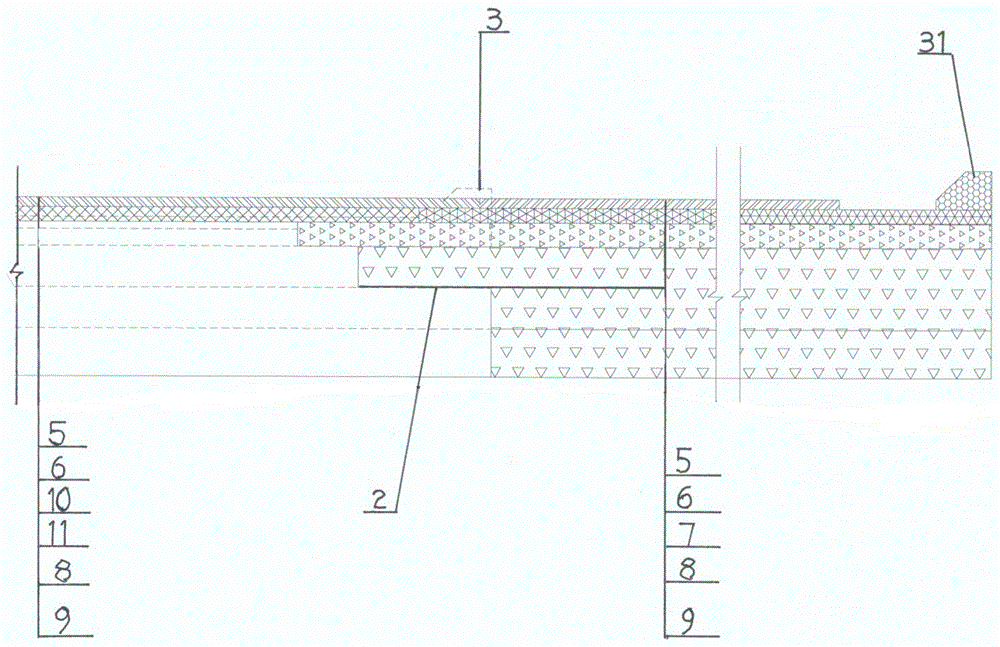

[0034] Such as figure 1 and figure 2 As shown, a splicing method of new and old roads in the reconstruction and expansion of road construction. Including the following steps:

[0035] (1) Excavation of hard shoulder steps on old pavement. According to the strength of the old pavement base course and subbase course obtained from the test, respectively adopt:

[0036] (a) When the strength of the base and subbase of the old pavement reaches the national standard, avoid the wheel load position and adopt the basic step excavation plan. The base can be called the water-stabilized gravel base 8, and the sub-base can be called the water-stabilized gravel sub-base 9.

[0037] The basic step excavation plan is: milling 1.9 m to 2.1 m from the hard shoulder marking line (including the marking line) of the old road to the outside of the road, and milling off the asphalt pavement layer. The anti-collision barrier on the old road is moved to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com