Treatment method capable of improving flexibility and strength of linen fabric

A processing method and flexibility technology, applied in the field of processing to improve the flexibility and strength of burlap fabrics, can solve the problems of the quality of burlap fabrics, mechanical properties and other quality decline, unfavorable comprehensive quality and other problems, and achieve great market competitiveness and production efficiency. , the effect of increasing weight and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

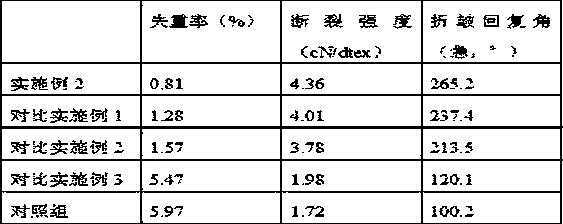

Examples

Embodiment 1

[0026] A processing method for improving the flexibility and strength of linen cloth, specifically treating the hemp plant fiber used for weaving the linen cloth, comprising the following steps:

[0027] (1) Cleaning treatment:

[0028] Put the hemp fiber into clean water for 1 hour, soak and clean it for 1 hour, take it out and put it in a cool place to dry naturally for later use;

[0029] (2) High temperature and high pressure treatment:

[0030] Put the hemp plant fiber treated in step (1) into a closed tank, introduce high-temperature water vapor into the closed tank, and increase the pressure in the closed tank to 0.4MPa, heat and maintain pressure for 9 minutes, and then Unload the airtight tank to normal temperature and pressure within 35s, and finally take out the hemp plant fiber for later use;

[0031] (3) One-time soaking treatment:

[0032] Put the hemp plant fiber treated in step (2) into the primary soaking treatment solution, heat to keep the temperature of ...

Embodiment 2

[0043] A processing method for improving the flexibility and strength of linen cloth, specifically treating the hemp plant fiber used for weaving the linen cloth, comprising the following steps:

[0044] (1) Cleaning treatment:

[0045] Put the hemp fiber into clean water for 1.3 hours, soak and clean it for 1.3 hours, take it out and put it in a cool place to dry naturally for later use;

[0046] (2) High temperature and high pressure treatment:

[0047] Put the hemp plant fiber treated in step (1) into a closed tank, introduce high-temperature water vapor into the closed tank, and increase the pressure in the closed tank to 0.42MPa, heat and maintain pressure for 10 minutes, and then Unload the airtight tank to normal temperature and pressure within 35s, and finally take out the hemp plant fiber for later use;

[0048] (3) One-time soaking treatment:

[0049] Put the hemp plant fiber treated in step (2) into the primary soaking treatment solution, heat to keep the tempera...

Embodiment 3

[0060] A processing method for improving the flexibility and strength of linen cloth, specifically treating the hemp plant fiber used for weaving the linen cloth, comprising the following steps:

[0061] (1) Cleaning treatment:

[0062] Put the hemp plant fiber into clean water for 1.5 hours, soak and clean it for 1.5 hours, take it out and put it in a cool place to dry naturally for later use;

[0063] (2) High temperature and high pressure treatment:

[0064] Put the hemp plant fiber treated in step (1) into a closed tank, introduce high-temperature water vapor into the closed tank, and increase the pressure in the closed tank to 0.45MPa, heat and maintain pressure for 11 minutes, and then Unload the airtight tank to normal temperature and pressure within 35s, and finally take out the hemp plant fiber for later use;

[0065] (3) One-time soaking treatment:

[0066] Put the hemp plant fiber treated in step (2) into the primary soaking treatment solution, heat to keep the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com