Hydrophobic anti-oxidation electric power silicone rubber protection tube

An anti-oxidation and silicone rubber technology, which is applied in the field of hydrophobic and anti-oxidative power silicone rubber protection tubes, can solve the problems of limited application and poor shielding, and achieve a good three-dimensional network molecular structure, good environmental stress resistance, and embrittlement. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to a hydrophobic and anti-oxidation electric silicone rubber protective tube and a preparation method thereof. The protective tube is composed of the following raw materials in parts by weight:

[0040] 85 parts of phenylene ether silicone rubber;

[0041] 8 parts of 4-4'-dimorpholine disulfide;

[0042] 17 parts of niobium yttrium tailings powder;

[0043] 5 parts of high iron microbeads;

[0044] 6 parts of hydroxyacrylic resin;

[0045] 3 parts of 100,000 viscosity HPMC;

[0046] Prisan PL-80 1.5 copies;

[0047] 2 parts of cross-linking auxiliary agent;

[0048] 2 parts of composite anti-aging agent;

[0049] Composite coupling agent 1 part.

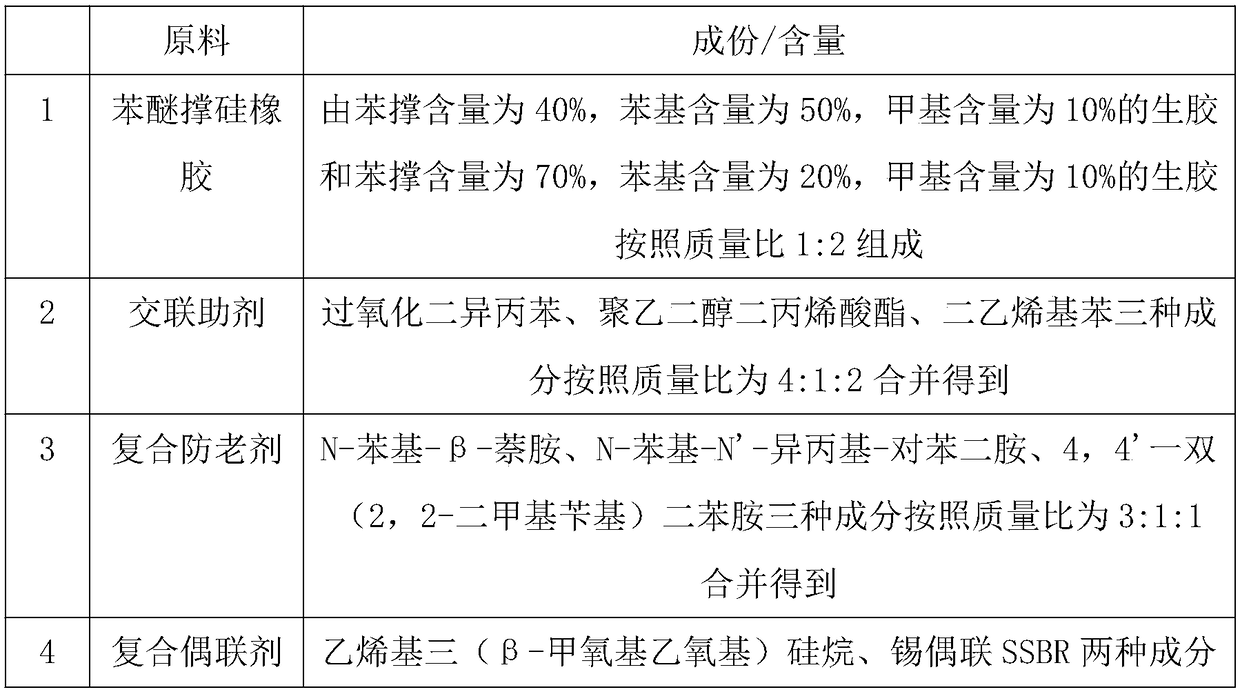

[0050] The selection and preparation of phenylene ether silicone rubber, composite anti-aging agent, composite coupling agent and crosslinking auxiliary agent in this example are shown in Table 1 below:

[0051] Table 1

[0052]

[0053]

[0054] The preparation method of the protection t...

Embodiment 2

[0059] This embodiment relates to a hydrophobic and anti-oxidation electric silicone rubber protective tube and a preparation method thereof. The protective tube is composed of the following raw materials in parts by weight:

[0060] 92 parts of phenylene ether silicone rubber;

[0061] 10 parts of 4-4'-dimorpholine disulfide;

[0062] 19 parts of niobium yttrium tailings powder;

[0063] 5.5 parts of high iron microbeads;

[0064] 6.5 parts of hydroxyacrylic resin;

[0065] 3.5 parts of 100,000 viscosity HPMC;

[0066] Prisan PL-80 1.8 copies;

[0067] 2.4 parts of cross-linking auxiliary agent;

[0068] 2.3 parts of compound antioxidant;

[0069] Composite coupling agent 1.4 parts.

[0070] The selection and preparation of phenylene ether silicone rubber, composite anti-aging agent, composite coupling agent and crosslinking auxiliary agent in this example are shown in Table 2 below:

[0071] Table 2

[0072]

[0073]

[0074] The preparation method of the prot...

Embodiment 3

[0079] This embodiment relates to a hydrophobic and anti-oxidation electric silicone rubber protective tube and a preparation method thereof. The protective tube is composed of the following raw materials in parts by weight:

[0080] 94 parts of phenylene ether silicone rubber;

[0081] 11 parts of 4-4'-dimorpholine disulfide;

[0082] 21 parts of niobium yttrium tailings powder;

[0083] 6 parts of high iron microbeads;

[0084] 7 parts of hydroxyacrylic resin;

[0085] 100,000 viscosity HPMC 4 parts;

[0086] Prisan PL-802 copies;

[0087] 2.6 parts of cross-linking auxiliary agent;

[0088] 2.5 parts of compound antioxidant;

[0089] Composite coupling agent 1.5 parts.

[0090] The selection and preparation of phenylene ether silicone rubber, composite anti-aging agent, composite coupling agent and crosslinking auxiliary agent in this example are shown in Table 3 below:

[0091] table 3

[0092]

[0093] The preparation method of the protection tube in this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com