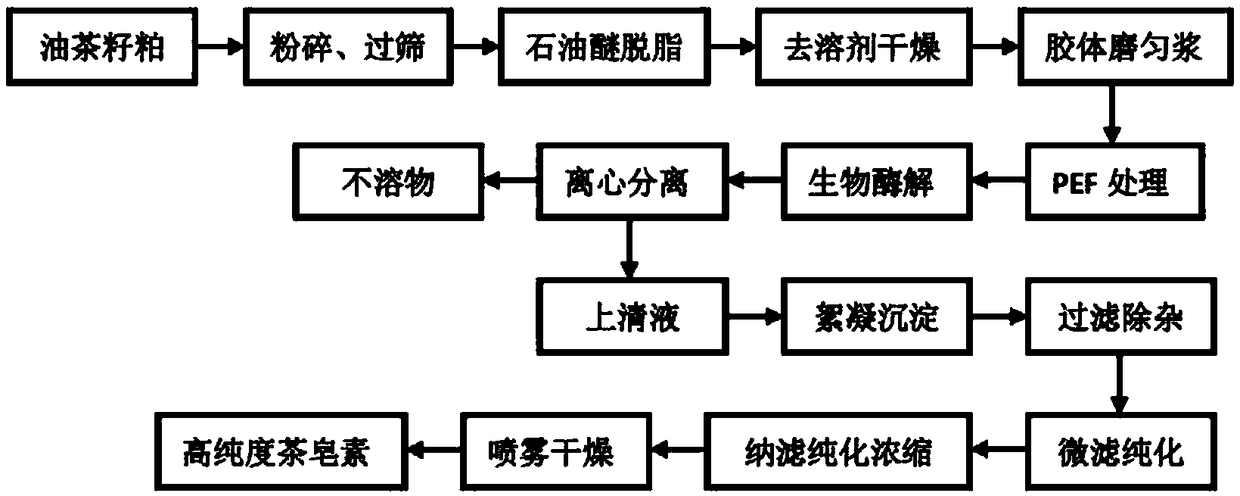

Method for preparing tea saponin under coupled action of high-voltage pulsed electric field and biological enzymatic hydrolysis

A high-voltage pulsed electric field and tea saponin technology, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problem of unextracted tea saponin, achieve no chemical reagent pollution, and realize high-value utilization , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Crush 500g of tea seed meal into powder, pass through a 60-mesh sieve to obtain tea seed meal powder; in a 90°C water bath, use petroleum ether with a boiling range of 60-90°C to remove the tea seed meal powder by Soxhlet extraction Grease, extract for 120 minutes, 5 minutes per siphon; after the Soxhlet extraction, dry naturally until there is no petroleum ether smell; take the degreased dry tea seed meal powder and add distilled water at a solid-to-liquid ratio of 1:20 (g:mL) , using a colloid mill (JMS-50 type, Langfang Guantong Machinery Co., Ltd., the same below) for homogenization for 5 minutes to obtain a uniform tea seed meal homogenate;

[0032] 2) The tea seed meal homogenate obtained in step 1) was pumped into the high-voltage pulsed electric field treatment chamber (SY-2-500 high-voltage pulsed electric field treatment device, South China University of Technology Light Industry and Food Science and Technology Co., Ltd. Researched and developed by the coll...

Embodiment 2

[0037] 1) Crush 500g of tea seed meal into powder, pass through a 60-mesh sieve to obtain tea seed meal powder; in a 90°C water bath, use petroleum ether with a boiling range of 60-90°C to remove the tea seed meal powder by Soxhlet extraction Grease, extract for 120 minutes, 5 minutes per siphon; after the Soxhlet extraction, dry naturally until there is no petroleum ether smell; take the degreased dry tea seed meal powder and add distilled water at a solid-to-liquid ratio of 1:10, and use colloidal grinding Slurry for 5 minutes to obtain a uniform tea seed meal homogenate;

[0038] 2) The tea seed meal homogenate obtained in step 1) is pumped into a high-voltage pulse electric field treatment chamber through a peristaltic pump at a flow rate of 5 mL / min, and subjected to high-voltage pulse electric field treatment with an electric field intensity of 20 kV / cm and a pulse number of 10;

[0039] 3) Take the tea seed dregs solution after the high-voltage pulse battery treatment, an...

Embodiment 3

[0043] 1) Crush 500g of tea seed meal into powder, pass through a 60-mesh sieve to obtain tea seed meal powder; in a 90°C water bath, use petroleum ether with a boiling range of 60-90°C to remove the tea seed meal powder by Soxhlet extraction Grease, extract for 120 minutes, 5 minutes per siphon; after the Soxhlet extraction, dry naturally until there is no petroleum ether smell; take the degreased dry tea seed meal powder and add distilled water at a solid-to-liquid ratio of 1:10, and use colloidal grinding Slurry for 5 minutes to obtain a uniform tea seed meal homogenate;

[0044] 2) The tea seed meal homogenate obtained in step 1) is pumped into a high-voltage pulse electric field treatment chamber through a peristaltic pump at a flow rate of 5 mL / min, and subjected to high-voltage pulse electric field treatment with an electric field intensity of 20 kV / cm and a pulse number of 10;

[0045] 3) Take the tea seed dregs solution after the high-voltage pulse battery treatment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com