Fabrication method and application of hydrophobic/light trapping fly-eye lens array with micro-nano double-level structure

A technology of microlens array and fly-eye lens, which is applied in applications, household appliances, optical components, etc., can solve the problems of narrow material selection range, harsh conditions, and cumbersome processes, etc., and achieve easy-to-operate procedures, simple and easy manufacturing methods, and promising application prospects broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in combination with specific embodiments.

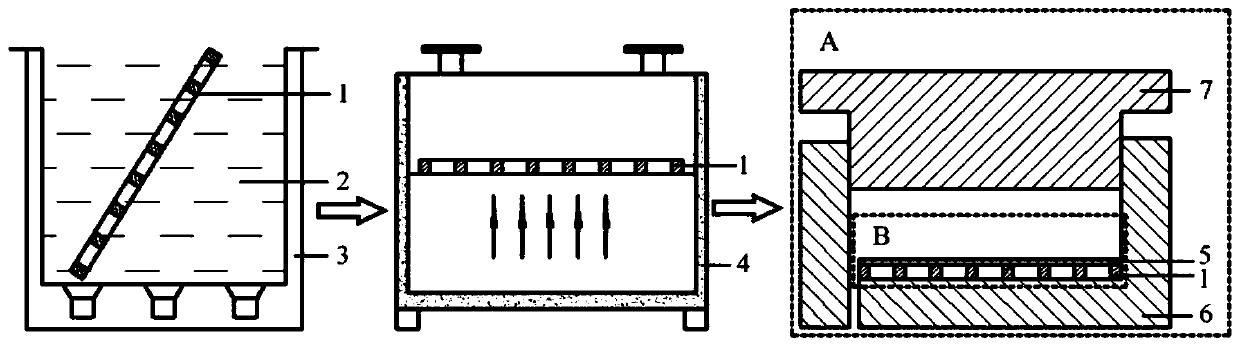

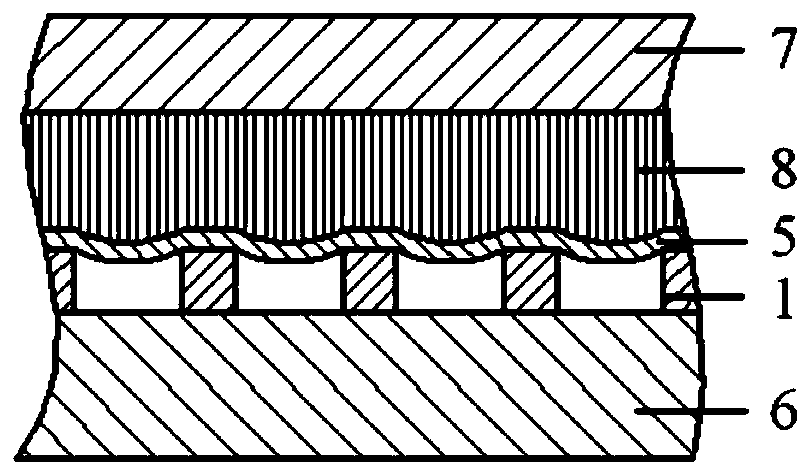

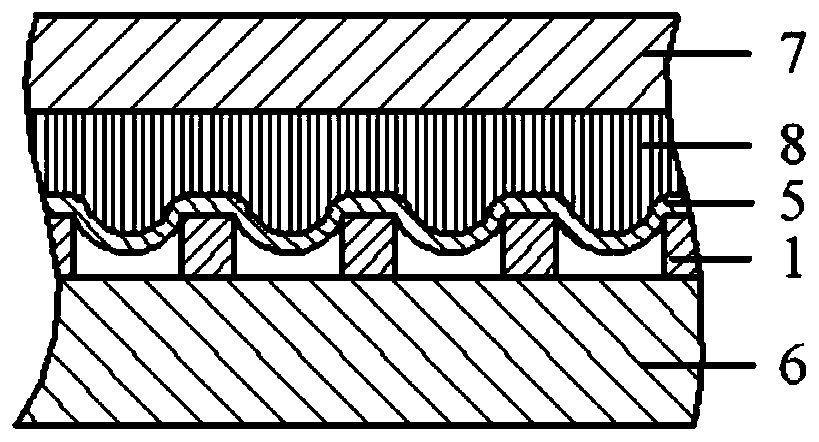

[0039] figure 1 A schematic diagram showing the process of manufacturing the flexible microlens array template and fixing it on the cavity surface of the injection mold according to the present invention. A porous plate 1 with a hole diameter of 250 μm and a hole spacing of 320 μm was immersed in absolute ethanol 2 for ultrasonic cleaning for 20 min, and then dried in an oven 4 . The flexible film 5 is tightly pasted on one side of the washed and dried porous plate 1 to make a flexible microlens array template B. Fix the flexible microlens array template B on the cavity surface of the fixed mold 6 in the injection mold A.

[0040] Figure 2a~2c It shows a schematic diagram of the process of manufacturing PS products with microlens arrays on the surface by injection molding in the present invention. Heating the injection mold A, using an injection molding machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com