Carbon nitride quantum dot/titanium dioxide sol and preparation method thereof

A technology of titanium dioxide and quantum dots, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high preparation cost, low quantum yield, poor dispersion, etc., and achieve high quantum yield , strong catalytic activity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

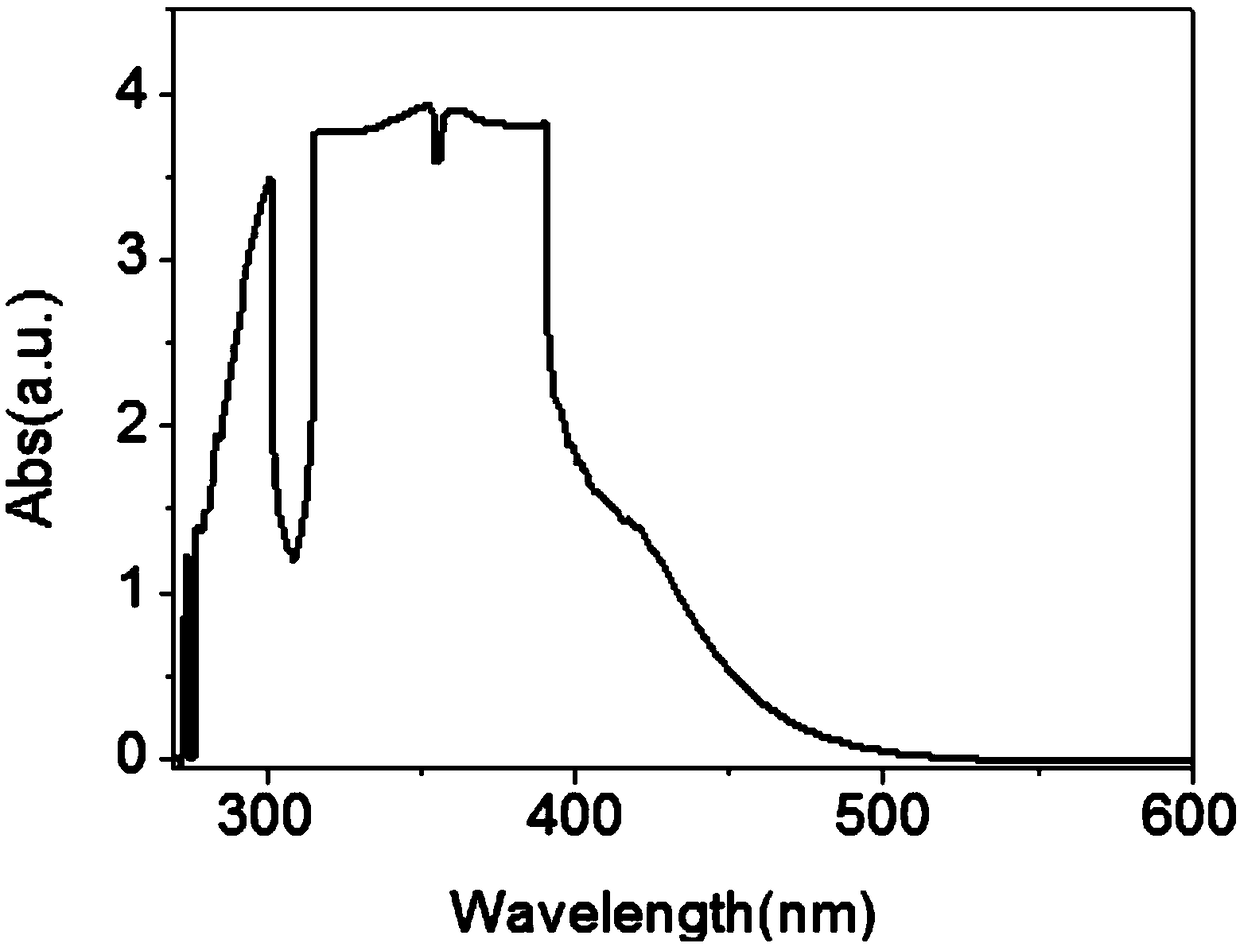

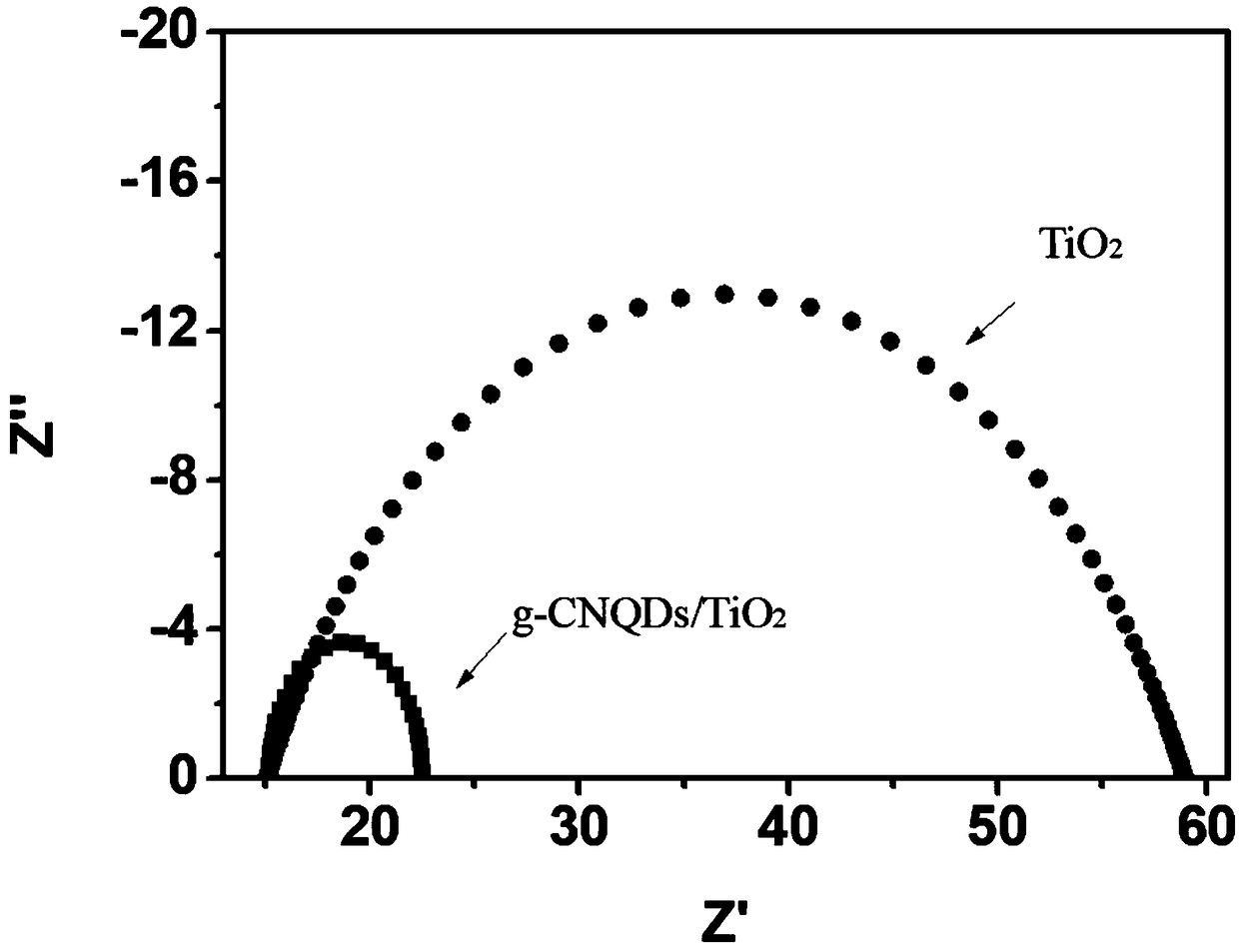

[0026] Embodiment 1: A kind of preparation method of carbon nitride quantum dot / titanium dioxide

[0027] 1. Preparation of Carbon Nitride Quantum Dots (g-CNQDS)

[0028] 5g of melamine was used as a precursor, calcined to 600°C in a muffle furnace, kept for 3 hours, cooled naturally, taken out, and ground to obtain powdered g-C 3 N 4 . Powdered g-C 3 N 4 Mix evenly with the ammoniacal liquor that volume fraction is 26%, described g-C 3 N 4 The mass-volume ratio of the powder to ammonia water is 1:250, and then placed in a polytetrafluoroethylene reactor at 180°C for hydrothermal reaction for 11 hours. After taking it out, the ammonia water is evaporated by rotary evaporation, and the light white g-C3N4 quantum dot liquid is obtained by ultrasonication. The ultrasonic frequency is 25KHz, and the ultrasonic time is 2 hours.

[0029] 2. Preparation of carbon nitride quantum dots / titanium dioxide sol

[0030]At a low temperature of 0°C, add 1ml of titanium tetrachloride t...

Embodiment 2

[0038] Embodiment 2 A kind of preparation method of carbon nitride quantum dot / titanium dioxide

[0039] 1. Carbon nitride quantum dots (g-CNQD S ) preparation

[0040] 5g of melamine was used as a precursor, calcined to 500°C in a muffle furnace, kept for 1 hour, cooled naturally, taken out, and ground to obtain powdered g-C 3 N 4 . Powdered g-C 3 N 4 Mix evenly with ammonia water with a volume fraction of 25%, the g-C 3 N 4 The mass volume ratio of the powder to ammonia water is 1:200, and then placed in a polytetrafluoroethylene reactor at 170°C for hydrothermal reaction for 10 hours. After taking it out, the ammonia water is evaporated by rotary evaporation, and the light white g-C3N4 quantum dot liquid is obtained by ultrasonication. The ultrasonic frequency is 20KHz, and the ultrasonic time is 1 hour.

[0041] 2. Preparation of carbon nitride quantum dots / titanium dioxide sol

[0042] At a low temperature of 0°C, add 1ml of titanium tetrachloride to a mixed solv...

Embodiment 3

[0044] Embodiment 3: A kind of preparation method of carbon nitride quantum dot / titanium dioxide

[0045] 1. Carbon nitride quantum dots (g-CNQD S ) preparation

[0046] 5g of melamine was used as a precursor, calcined to 700°C in a muffle furnace, kept for 1 hour, cooled naturally, taken out, and ground to obtain powdered g-C 3 N 4 . Powdered g-C 3 N 4 Mix evenly with the ammoniacal liquor that volume fraction is 28%, described g-C 3 N 4 The mass-volume ratio of the powder to ammonia water is 1:300, and then placed in a polytetrafluoroethylene reactor at 190°C for hydrothermal reaction for 12 hours. After taking it out, the ammonia water is evaporated by rotary evaporation, and the light white g-C3N4 quantum dot liquid is obtained by ultrasonication. The ultrasonic frequency is 30KHz, and the ultrasonic time is 3 hours.

[0047] 2. Preparation of carbon nitride quantum dots / titanium dioxide sol

[0048] At a low temperature of 0°C, add 5ml of titanium tetrachloride t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com