Low-temperature SCR manganese oxide catalyst as well as preparation method and application thereof

A manganese oxide and catalyst technology, which is applied in the field of low-temperature SCR manganese oxide catalyst and its preparation, can solve the problem of low low-temperature activity and achieve the effects of simple process, good low-temperature SCR denitrification activity, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a low-temperature SCR manganese oxide catalyst. Prepared by the following method.

[0033] Add sodium permanganate to 80mL of distilled aqueous solution, add hydrochloric acid to adjust the hydrogen ion concentration of the solution to 0.2mol / L (the molar ratio of sodium permanganate to hydrogen ion concentration is equal to 1), and stand at 80°C for reaction 6h, the resulting product was filtered, washed and then dried to obtain manganese dioxide. Then the manganese dioxide was calcined at 400° C. for 3 hours to obtain the manganese oxide catalyst.

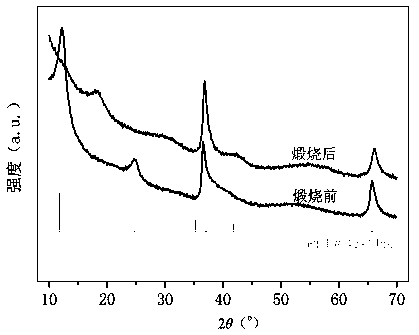

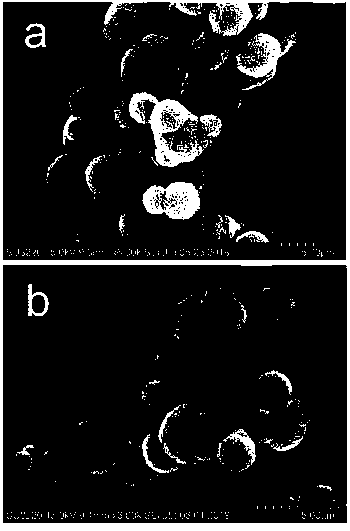

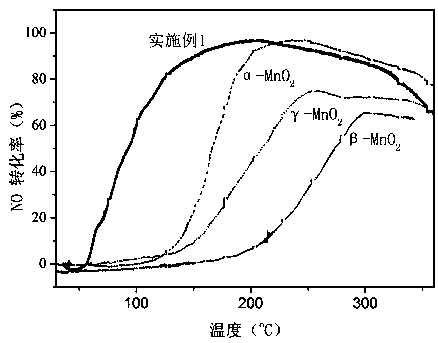

[0034] The above-mentioned manganese oxide is characterized, and its XRD diffraction pattern is as follows figure 1 shown. We know that manganese oxide before calcination and δ-MnO indicated by JCPDF standard card PDF#43-1456 2 Correspondingly, but after calcination at 400 °C, the XRD crystal form collapsed unexpectedly, forming an amorphous structure. figure 2 Scanning electron micrographs o...

Embodiment 2

[0038] This embodiment provides a low-temperature SCR manganese oxide catalyst. Prepared by the following method.

[0039] Add sodium permanganate to 80mL of distilled aqueous solution, add hydrochloric acid to adjust the hydrogen ion concentration of the solution to 0.2mol / L (the molar ratio of sodium permanganate to hydrogen ion concentration is 1.2), and stand at 80°C for reaction After 48 hours, the obtained product was filtered, washed and then dried to obtain manganese dioxide. Then the manganese dioxide was calcined at 300° C. for 3 h to obtain the manganese oxide catalyst. After testing, its XRD and SEM are similar to Example 1.

Embodiment 3

[0041] This embodiment provides a low-temperature SCR manganese oxide catalyst. Prepared by the following method.

[0042]Add sodium permanganate to 80mL of distilled aqueous solution, add sulfuric acid to adjust the hydrogen ion concentration of the solution to 0.2mol / L (the molar ratio of sodium permanganate to hydrogen ion concentration is 1.2), and stand at 40°C for reaction After 48 hours, the obtained product was filtered, washed and then dried to obtain manganese dioxide. Then the manganese dioxide was calcined at 300° C. for 5 h to obtain the manganese oxide catalyst. After testing, its XRD and SEM are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com