Tributyrin microcapsule with maltodextrin and cyclodextrin as wall material

A technology of tributyrin microcapsules and tributyrin, applied in the production/processing of edible oil/fat components, edible oil/fat, etc., can solve the problems of poor particle solubility and application limitations, and achieve preparation Simple process, convenient operation, good solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 The impact of the type of maltodextrin on the stability of tributyrin microcapsules

[0023] The preparation process of tributyrin powder oil is carried out as follows:

[0024] (1) Add maltodextrin and cyclodextrin into distilled water, heat in a water bath at 50-80°C and mix evenly;

[0025] (2) Add tributyrin and emulsifier to the mixed solution obtained in (1), fully stir;

[0026] (3) The mixture obtained in (2) is sheared intermittently for 2 to 5 minutes at 8,000 to 20,000 rpm (increasing the speed step by step) with a high-speed shearer, and then homogenized for 2 to 3 minutes with a high-pressure homogenizer at a pressure of 30 to 40 MPa. times, and finally carry out spray drying to obtain tributyrin microcapsule powder product. The operating parameters of the spray drying are as follows: the inlet air temperature is 180-185°C, the outlet air temperature is 85-95°C, and the feed flow rate is 20-22mL / min.

[0027] Wherein, the weight composition of ...

Embodiment 2

[0029] Embodiment 2 The influence of the amount of maltodextrin added on the stability of tributyrin microcapsules

[0030] The preparation process of tributyrin powder oil is carried out according to embodiment 1, wherein, malt paste selection is carried out with DE=10, and each material weight composition is carried out according to the following 5 groups:

[0031] Experimental group 1: maltodextrin 12%, cyclodextrin 3%, tributyrin 8%; Tween 5%, water 72%;

[0032] Experimental group 2: maltodextrin 16%, cyclodextrin 3%, tributyrin 8%; Tween 5%, water 68%;

[0033] Experimental group 3: maltodextrin 20%, cyclodextrin 3%, tributyrin 8%; Tween 5%, water 64%;

[0034] Experimental group 4: maltodextrin 24%, cyclodextrin 3%, tributyrin 8%; Tween 5%, water 60%;

[0035] Experimental group 5: maltodextrin 28%, cyclodextrin 3%, tributyrin 8%, Tween 5%, water 54%.

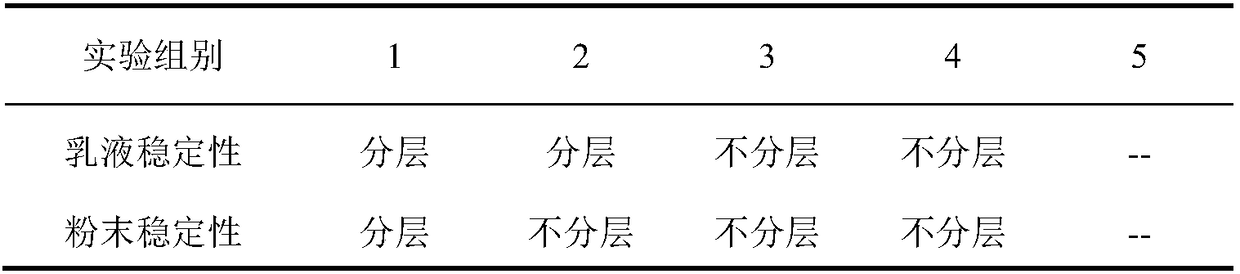

[0036] Table 1 shows the phenomenon of the emulsions obtained in the above 5 groups and the solutions obtained afte...

Embodiment 3

[0040] The influence of embodiment 3 cyclodextrin addition amount on tributyrin microcapsule stability

[0041] The preparation process of tributyrin powder oil is carried out by embodiment 1, wherein, each material weight composition is carried out by following 5 groups:

[0042] Experimental group 1: maltodextrin 20%, cyclodextrin 0%, tributyrin 8%; Tween 5%, water 67%;

[0043] Experimental group 2: maltodextrin 20%, cyclodextrin 2%, tributyrin 8%; Tween 5%, water 65%;

[0044] Experimental group 3: maltodextrin 20%, cyclodextrin 3%, tributyrin 8%; Tween 5%, water 64%;

[0045] Experimental group 4: maltodextrin 20%, cyclodextrin 4%, tributyrin 8%; Tween 5%, water 63%;

[0046] Experimental group 5: maltodextrin 20%, cyclodextrin 5%, tributyrin 8%, Tween 5%, water 62%.

[0047] Table 2 shows the phenomenon of the emulsions obtained in the above 5 groups and the solutions obtained after dissolving the powdered oils after being placed for 15 days. Among them, the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com