Spraying auxiliary agent and preparation method thereof as well as spraying liquid containing spraying auxiliary agent

A technology for spraying adjuvant and spraying liquid, applied in the field of pesticides, can solve the problems of complex composition of spraying adjuvant, narrow application range, low stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

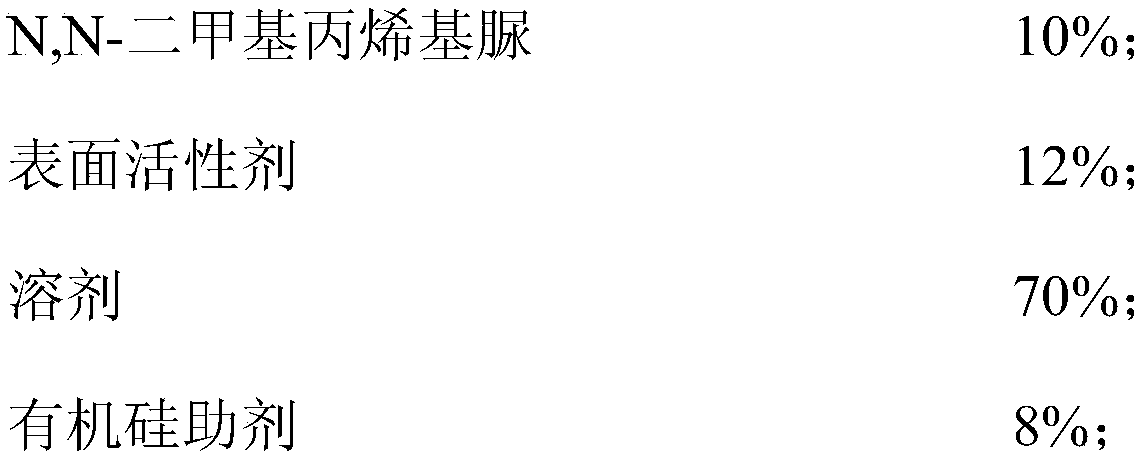

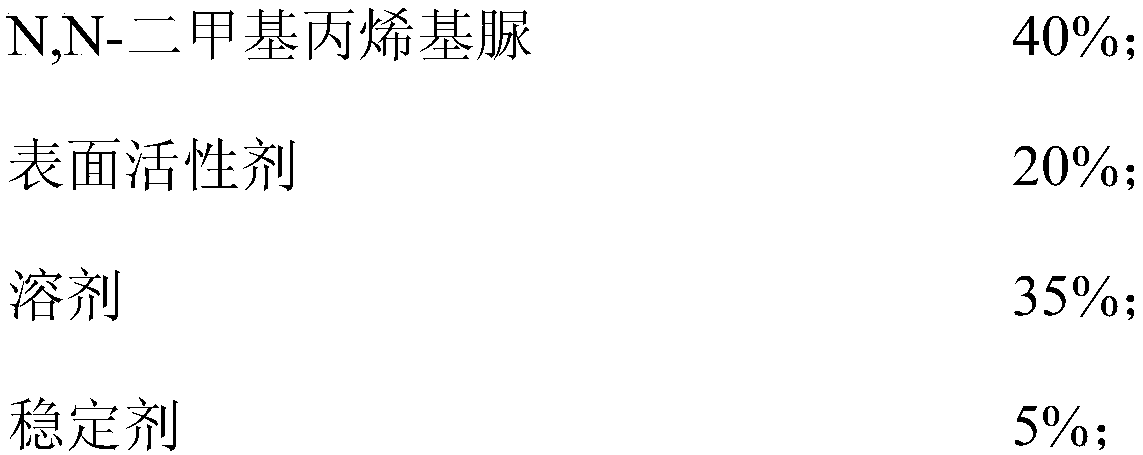

[0068] A spraying aid, by mass percentage, consists of the following components:

[0069] N,N-Dimethylpropenylurea 40%;

[0070] Surfactant 16%;

[0071] Solvent 44%;

[0072] Wherein, the surfactant is a combination of calcium dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ether and alkylamide betaine, and the ratio of the three can be arbitrary; the solvent is soybean oil.

[0073] The preparation method is as follows: uniformly mixing N,N-dimethylpropenyl urea, surfactant and solvent in the formulated amount to obtain the spray aid.

preparation example 2-5

[0075] The only difference from Preparation Example 1 is that the amount of N,N-dimethylallyl urea added is 10% (Preparation Example 2), 60% (Preparation Example 3), 84% (Preparation Example 4), 8% ( Preparation example 5), meanwhile, the addition amount of surfactant is unchanged, and the addition amount of solvent is changed to 100%.

preparation example 6-7

[0077] The only difference with Preparation Example 1 is that in this embodiment, the surfactant is a combination of fatty alcohol polyoxyethylene ether phosphate and sulfosuccinate in any proportion (Preparation Example 6), cocamidopropyl betaine (Preparation Example 7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com