Outdoor optical cable with excellent anti-electromagnetic performance

An outdoor optical cable, anti-electromagnetic technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of optical cable waterproof performance and electrical insulation, anti-electromagnetic shielding performance, reduce optical cable waterproof performance and anti-electromagnetic performance, increase optical cable transmission loss, etc., to achieve Good anti-electromagnetic performance, excellent shielding performance and mechanical properties, good interface bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

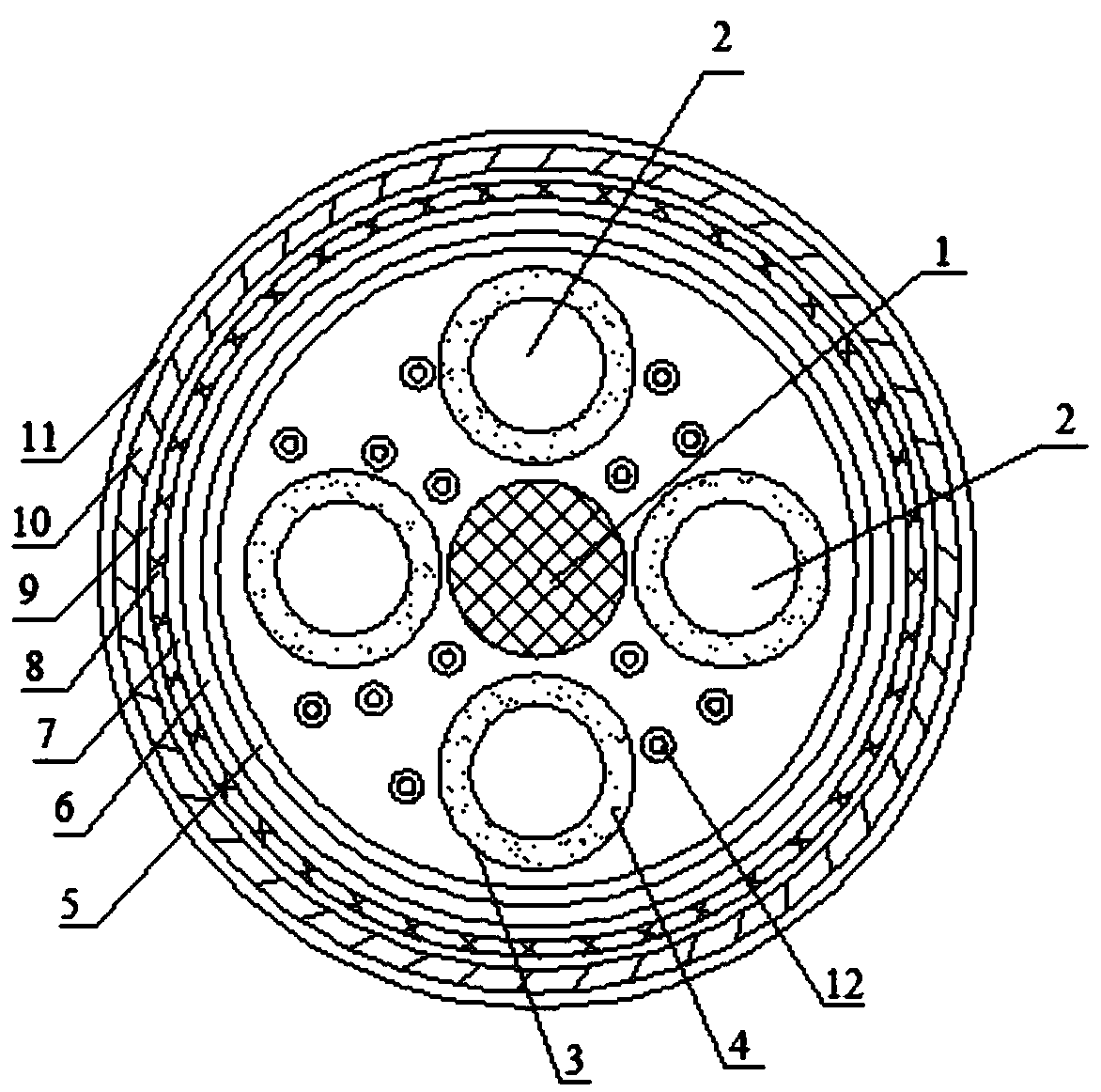

[0024] see figure 1 As shown, an outdoor optical cable with excellent electromagnetic resistance performance includes a central reinforcing steel wire 1, several cable cores 2 around the outer side of the central reinforcing steel wire 1, and a loose tube 3 is set on the periphery of the cable core 2, and a loose tube 3 is placed inside the loose tube 3 Filled with fiber paste 4. The outer side of the loose tube 3 is provided with a water-blocking layer 5, and the water-blocking layer is made of non-conductive polyester tape with a thickness of 0.25±0.03mm. The outer side of the water blocking layer 5 is provided with an inner insulating layer 6 , a shielding layer 7 , a braided layer 8 , and a first protective layer 9 in sequence. A galvanized steel wire 10 is wound around the first protective layer 9 , and a second protective layer 11 is wrapped around the galvanized steel wire 10 . The outer periphery of the loose tube 3 is provided with a spiral water blocking strip 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com