Process for preparing foam magnesium

A preparation process and technology of foamed magnesium, which is applied in the field of metal material processing, can solve problems such as unevenness and difficult pore structure, and achieve the effects of good damping, high strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

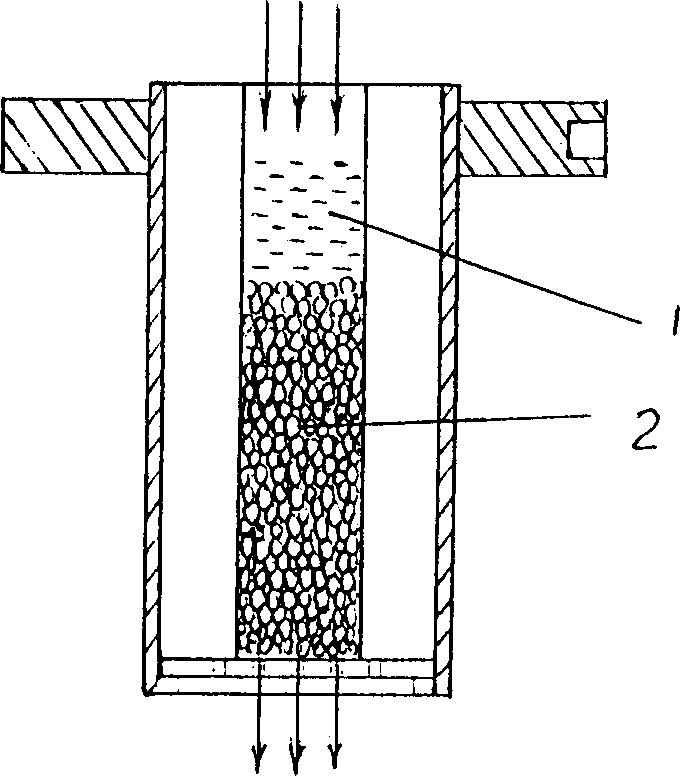

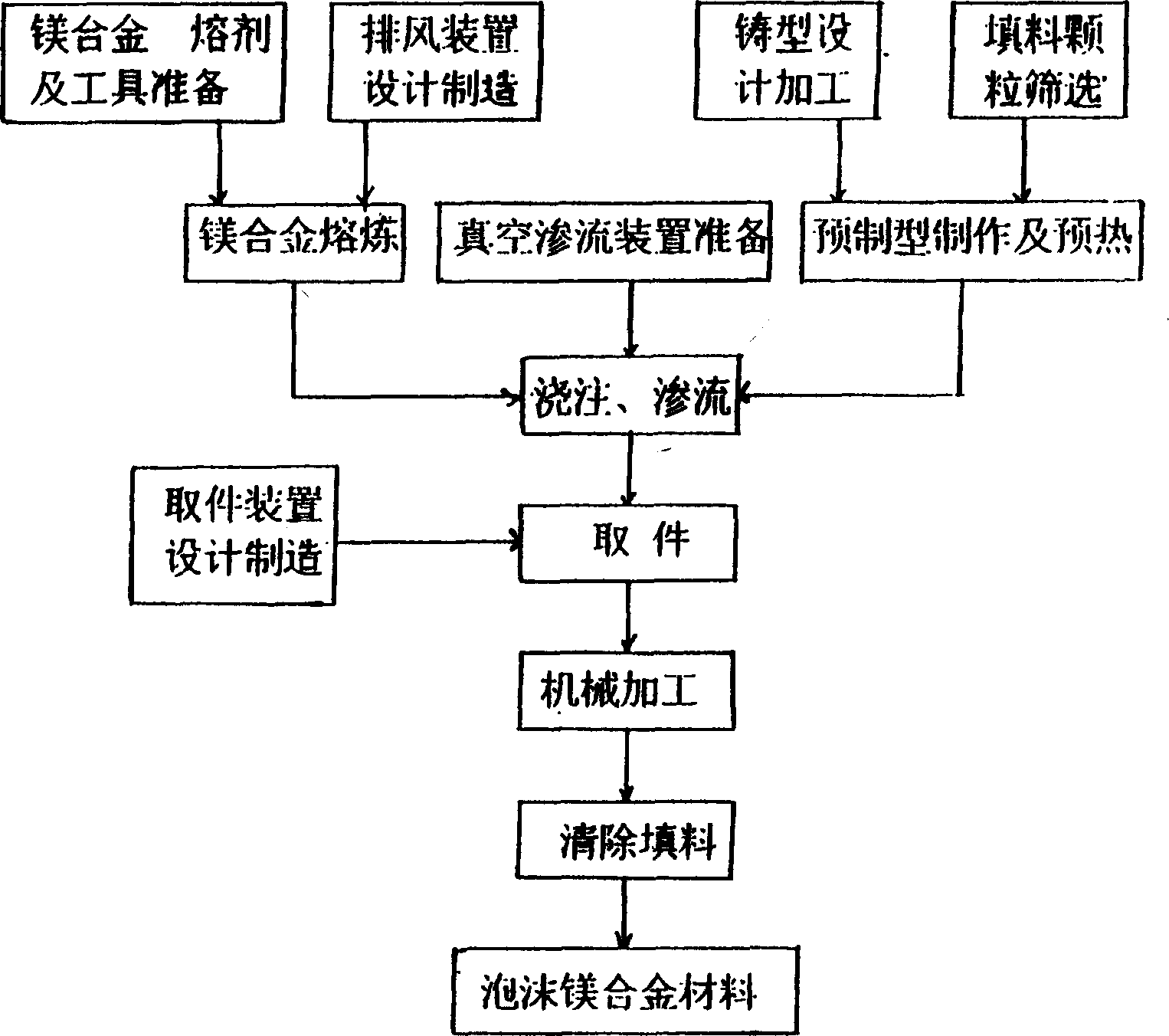

[0019] The present invention is a kind of foamed magnesium preparation process, and the vacuum infiltration process flow of the present invention is as follows figure 2 , the principle of vacuum seepage is as attached figure 1 As shown, it includes smelting magnesium alloy to form magnesium liquid 1, making a vacuum infiltration device, selecting filler particles 2, preheating the preform, pouring infiltration, processing and molding, and removing filler particles. The selected filler particle size is between 16-32 mesh. The preheating temperature of the casting mold and the prefabricated mold is 530°C, and the pouring temperature is 700°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com