Test equipment for simulating reinforced concrete structure corrosion in seawater wave splashing environment

A reinforced concrete and simulated seawater technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of limited research, high transportation costs, slow corrosion speed, etc., and reduce the interference of human factors, test Reliable results, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

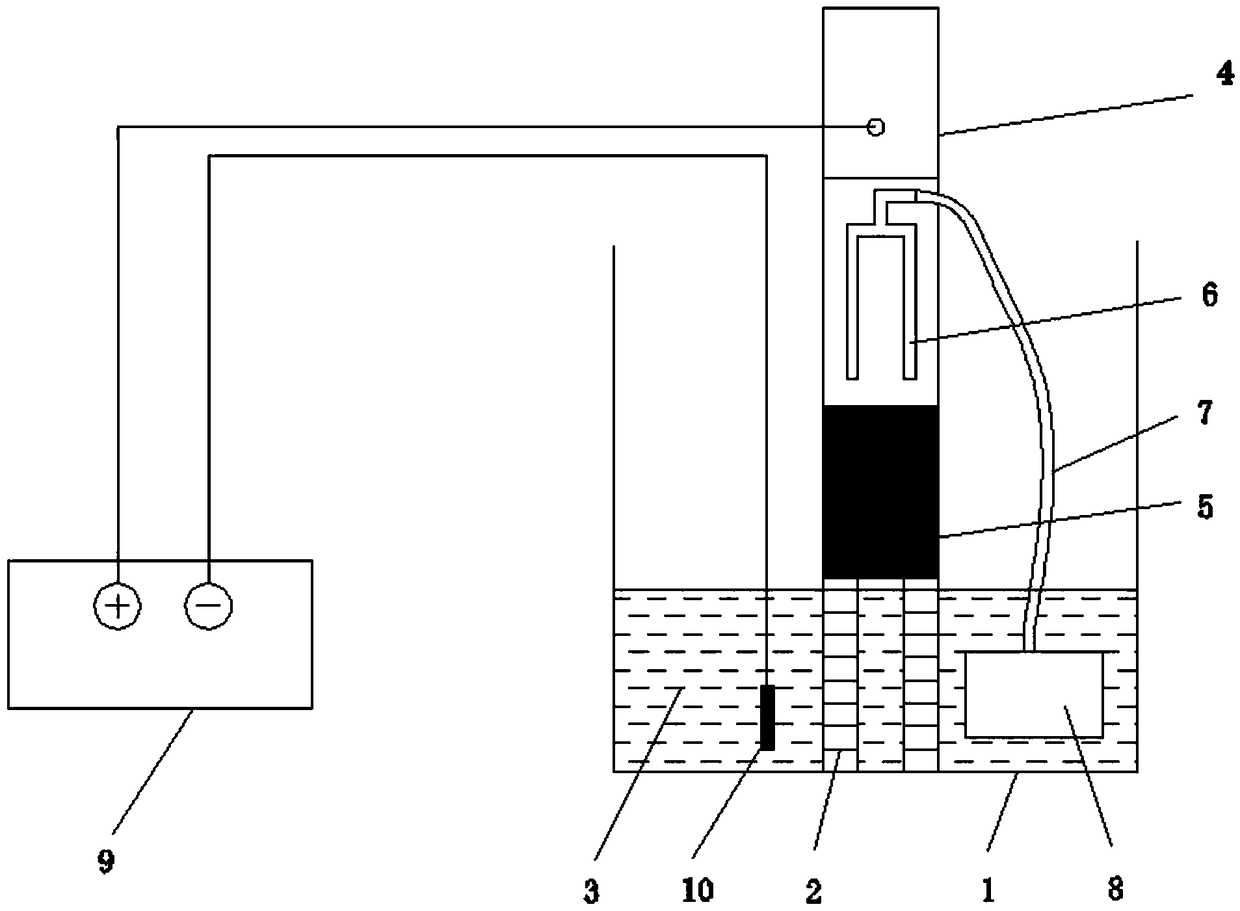

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 and figure 2 As shown, a test equipment for simulating the corrosion of reinforced concrete structures under seawater splashing environment, including a pool 1, a pad 2 is arranged in the middle of the pool 1, and a sodium chloride solution 3 is filled in the pool 1, and chlorine The height of the sodium chloride solution 3 is lower than the height of the block 2, the top of the block 2 is provided with a reinforced concrete member 4, and three-tenths of the bottom of the reinforced concrete member 4 is provided with an epoxy resin coating 5, The setting of the epoxy resin coating 5 prevents the sodium chloride solution 3 from penetrating into the concrete in this area, causing test deviation, and the side walls of the reinforced concrete member 4 at the top of the epoxy resin coating 5 are provided with PVC thermopla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com