Staged fracturing transformation process for increasing single well yield of ultra-low permeability reservoir horizontal well

A single-well production, staged fracturing technology, applied in wellbore/well valve devices, wellbore/well components, drilling equipment, etc., can solve the problem of underdeveloped natural fractures, strong heterogeneity, and ultra-low permeability problems such as low reservoir brittleness index, to achieve the effect of reducing operating costs, improving the pertinence of stimulation, and reducing the scale of stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides a staged fracturing reconstruction process for improving the production of a single well of a horizontal well in an ultra-low permeability reservoir, including determining the fracturing operation according to the characteristics that the natural fractures of the ultra-low permeability reservoir do not develop and the artificial fracture is a single fracture. The displacement is 3-4m 3 / min, and then use the coiled tubing fracturing string for fracturing.

[0031] In view of the low brittleness index of ultra-low permeability reservoirs, the relative lack of natural fractures, and the characteristics of artificial fractures mainly forming single fractures rather than "network" fractures, the fracturing displacement was reduced, and the displacement was reduced from 6 to 8m for volume fracturing. 3 / min reduced to 4m for conventional fracturing 3 / min.

[0032] Coiled tubing 4 under pressure operation method: on the one hand, because the fracturin...

Embodiment 2

[0034] On the basis of Embodiment 1, this embodiment provides a staged fracturing reconstruction process for increasing single-well production of horizontal wells in ultra-low permeability reservoirs, which also includes determining the interval between fractures to be 40-50m.

[0035] According to the downhole microseismic test results under low displacement conditions, the interval between sections is changed from the original 6m 3 / min volume fracturing 80-100m, reduced to 4m 3 40-50m / min under conventional fracturing, the contact area between hydraulic fractures and reservoirs is greatly increased by densely distributed fractures and increasing the number of fracturing stages.

[0036] Wherein, the permeability of the ultra-low permeability reservoir is less than 10 -3 μm 2 .

[0037] If the cracks are not developed, there are 1-2 groups of cracks with an interval of more than 1m.

[0038] In view of the characteristics of low brittleness index (less than 40) and relat...

Embodiment 3

[0040] On the basis of Embodiment 1, this embodiment provides a staged fracturing reconstruction process for increasing the single-well production of a horizontal well in an ultra-low permeability reservoir. The coiled tubing fracturing includes the following steps:

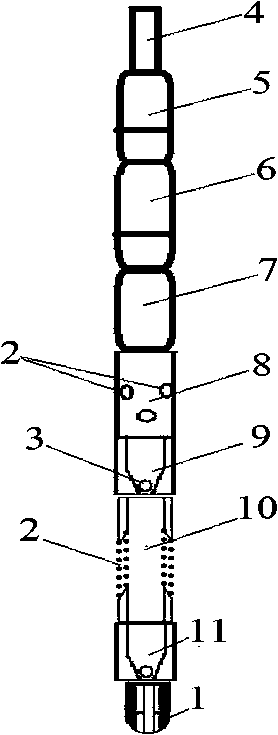

[0041] Step 1) Put the sealing ball 3 into the coiled tubing fracturing string, seat the sealing ball 3 into the ball seat 9, place the coiled tubing fracturing string in the well to be operated, and perform hydraulic sandblasting single shower through the spray gun 8 Hole operation and crack initiation test;

[0042] Step 2) Inject liquid through the annular space to establish a reverse circulation channel, carry the sealing ball 3 out of the ground, and open the channel 10 of the sand mixer;

[0043] Step 3) Through the spray gun 8 and the sand mixer 10 of the coiled tubing fracturing string, inject a high-sand ratio sand-carrying fluid into the well with a displacement of 3-4m 3 / min;

[0044] Step 4) Displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com