Blue ray and ultraviolet absorption adhesive tape and glue and preparation method thereof

A blue light absorber, UV absorber technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve appearance defects, small cracks are difficult to find, high defect rate, lighting brightness Weakness and other problems, to achieve the effect of increasing anti-blue light-ultraviolet protection, avoiding visual inspection errors, and simple and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

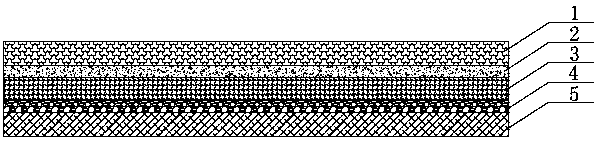

Image

Examples

Embodiment 1

[0039] Blue light-ultraviolet absorbing layer glue composition: the blue light absorbing agent is phenyl-modified ferrocene, its main absorption band is 350-420 nm, and the quantity is 15 parts. The ultraviolet absorber is a benzotriazole substance whose main absorption band is 300-390 nm, and the quantity is 10 parts. 100 parts of polyacrylate resin has a glass transition temperature of -55°C. C9 hydrogenated petroleum resin 70 parts, softening point temperature 110 ℃. Curing agent L-75, 20 parts. Solvent 150 parts of ethyl acetate, 80 parts of toluene, 20 parts of acetone.

[0040] Accurately weigh the raw materials of each component according to the material composition and ratio of the above formula, and dissolve the blue light absorber and ultraviolet absorber in 20 parts of acetone at a stirring speed of 350 rpm, and then add the remaining solvent and rosin glycerin After stirring for 15 minutes to fully dissolve, add polyacrylate resin, continue stirring for 15 minut...

Embodiment 2

[0045] Blue light-ultraviolet absorbing layer glue composition: The blue light absorbing agent is naphthyl-modified ferrocene, its main absorption band is 350-450 nm, and the quantity is 1 part. The ultraviolet absorber is a benzotriazole substance whose main absorption band is 280-380 nm, and the quantity is 1 part. 10 parts of polyacrylate resin, its glass transition temperature is -10°C. Rosin glyceride 5 parts, softening point temperature 75 ℃. Curing agent L-75, 1 part. The solvents are 50 parts of butyl acetate, 30 parts of toluene, and 20 parts of butanone.

[0046] Accurately weigh the raw materials of each component according to the material composition and ratio of the above formula, and dissolve the blue light absorber and ultraviolet absorber in 20 parts of methyl ethyl ketone under the condition of stirring speed of 100 rpm, and then add the remaining solvent and rosin Glyceride, stir for 15 minutes to fully dissolve, then add polyacrylate resin, continue stirr...

Embodiment 3

[0051] Blue light-ultraviolet absorbing layer glue composition: the blue light absorbing agent is ferrocene modified by dimethylphenyl, its main absorption band is 360-440 nm, and the quantity is 8 parts. The ultraviolet absorber is a benzotriazole substance whose main absorption band is 200-380 nm, and the quantity is 6 parts. 50 parts of polyacrylate resin, its glass transition temperature is -30°C. 35 parts of hydrogenated rosin glyceride, the softening point temperature is 95°C. Curing agent N3300, 10 parts. Solvent butanone 150 parts.

[0052] Accurately weigh the raw materials of each component according to the material composition and ratio of the above formula, and dissolve the blue light absorber and ultraviolet absorber in 20 parts of butanone at a stirring speed of 200 rpm, and then add the remaining solvent and rosin Glyceride, stir for 15 minutes to fully dissolve, then add polyacrylate resin, continue stirring for 15 minutes to completely dissolve, then add N3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com