Complete technology for treatment and disposal of sludge

A sludge treatment, complete set of technology, applied in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc., to achieve the effects of low cost, efficient utilization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

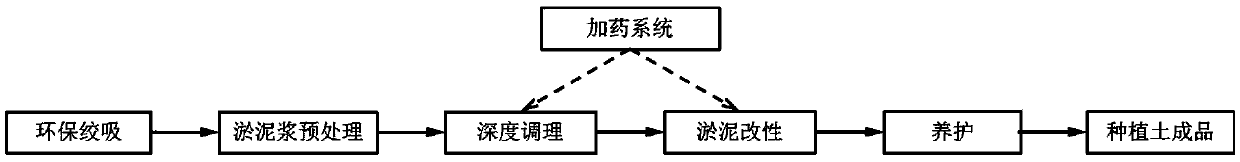

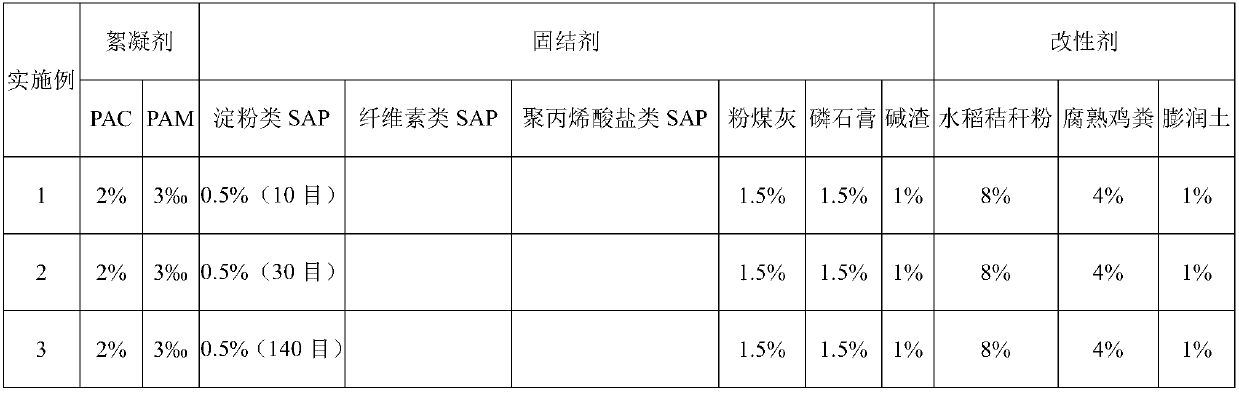

[0041] Embodiment 1-9 adopts following technological method to carry out processing disposal to sludge:

[0042] (1) Environmental protection dredging: the dredging operation is carried out through the environmental protection cutter suction type, and the sludge slurry is transported to the shore disposal center through pipelines for centralized treatment;

[0043] (2) Sludge slurry pretreatment: use gravity sedimentation and grid machine to remove large-sized gravel, mud, plastic bags, floating objects and other debris in the sludge, and the sludge slurry after removal of impurities flows into the adjustment tank for natural settlement ;

[0044] (3) Depth conditioning of sludge slurry: add flocculant to the pretreated sludge through the dosing system, and fully react through mechanical stirring to complete the flocculation and dehydration of the sludge slurry; after flocculation, the slurry is pumped into the pipeline mixer, and continuously through the dosing system Consol...

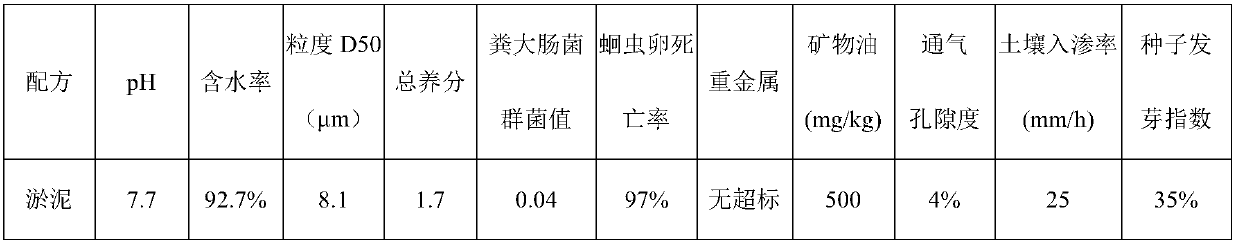

Embodiment 8

[0057] The appearance of the prepared silt planting soil in Example 8 shows a loose state, no peculiar smell and no obvious impurities; as can be seen from Table 4, its physical and chemical indicators such as water content and pH all reach the standard "Sludge Disposal of Urban Sewage Treatment Plants-Landscaping Use According to the requirements of Mud Quality (GB / T 23486-2009), its particle size has also been improved, which indirectly shows the cementation effect of the consolidation agent on fine particles; compared with the original silt, its air porosity and soil infiltration rate are both Significantly improved, reaching 26.4% and 151mm / h respectively, indicating that the prepared planting soil has a loose granulated structure, and its seed germination index has reached 92%, indicating that the silt planting soil has good activity and is suitable for plant growth.

[0058] In addition, the maximum water holding capacity of the silt planting soil in Example 8 reaches 172...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com