Water-borne hyperbranched structure modified polyurethane polymer and preparation method thereof, and self-repair diffuse reflection coating composition

A technology of polyurethane polymer and terminal hydroxyl hyperbranching, which is applied in polyurea/polyurethane coatings, reflection/signal coatings, coatings, etc. It can solve the problems of poor transparency, inability to form a space network structure, and insufficient hardness of coatings. Adjustable, reduced coating process difficulty, and no pollution to the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

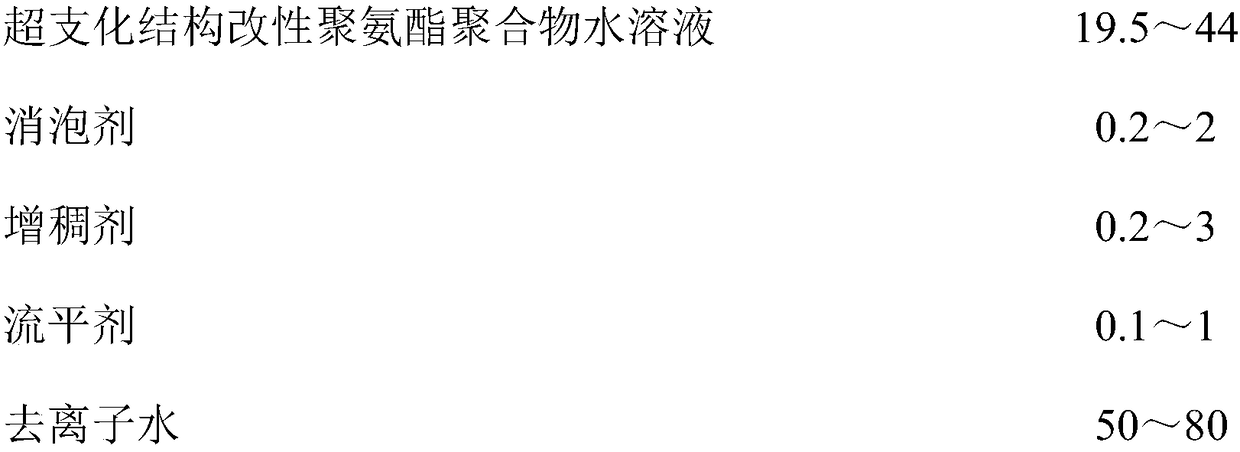

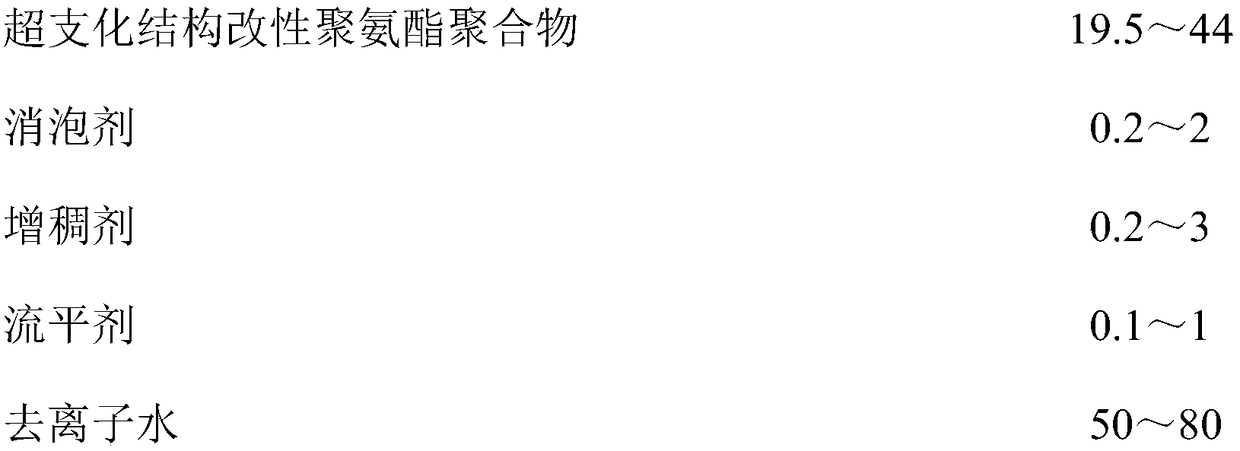

Embodiment 1

[0039] Take by weighing 200g (0.1mol) molecular weight is the aliphatic polyether diol of 2000g / mol, 200g (0.1mol) molecular weight is the aliphatic polyester diol of 2000g / mol, 100 ℃ of decompression dehydration, cooling to 60°C, blowing nitrogen, adding 0.1g catalyst dibutyltin dilaurate, 88.7g (0.4mol) isophorone diisocyanate, reacted for 3 hours. Add 2.7g (0.02mol) dimethylol propionic acid and react for 3 hours. Add 4.9 g of hydroxyl-terminated hyperbranched polyester (containing 0.015 mol of hydroxyl) with a molecular weight of 5000 g / mol and a functionality of 15, and react for 2 hours. Continue to add 1.4g (0.01mol) dimethylol propionic acid to react for 3 hours. Cool down to normal temperature, add 2g (0.02mol) neutralizing agent triethylamine, and stir for 10 minutes. Add 0.8g (0.002mol) diisooctyl sulfonate sodium succinate to prepare a hyperbranched structure modified polyurethane polymer.

[0040] Continue to add 500.5 g of deionized water, stir for 0.5 hour, a...

Embodiment 2

[0043] Take by weighing 200g (0.1mol) molecular weight is the aliphatic polyether diol of 2000g / mol, 100g (0.05mol) molecular weight is the aliphatic polyester diol of 2000g / mol, 100 ℃ of decompression dehydration, cooling to 60°C, blow nitrogen, add 0.1g catalyst dibutyltin dilaurate, 166.3g (0.75mol) isophorone diisocyanate, react for 5 hours. Add 30.2g (0.225mol) dimethylol propionic acid and react for 3 hours. Add 99.3 g of hydroxyl-terminated hyperbranched polyester (containing 0.3 mol of hydroxyl) with a molecular weight of 15 and a molecular weight of 5000 g / mol, and react for 2 hours. Continue to add 30.2g (0.225mol) dimethylol propionic acid to react for 3 hours. Cool down to normal temperature, add 45.5g (0.45mol) neutralizing agent triethylamine, and stir for 10 minutes. Add 52.8g (0.135mol) sodium diisooctyl sulfonate to prepare a hyperbranched structure modified polyurethane polymer.

[0044] Continue to add 724.3 g of deionized water, stir for 0.5 hour, and fi...

Embodiment 3

[0048] Take by weighing 200g (0.1mol) molecular weight is the aliphatic polyether diol of 2000g / mol, 20g (0.01mol) molecular weight is the aliphatic polyester diol of 2000g / mol, 100 ℃ of decompression dehydration, cooling to 70°C, blowing nitrogen, adding 0.1g catalyst dibutyltin dilaurate, 73.2g (0.33mol) hexamethylene diisocyanate, and reacting for 3 hours. Add 8.9g (0.066mol) of dimethylol propionic acid and react for 3 hours. Add 30.2 g of hydroxyl-terminated hyperbranched polyester (containing 0.009 mol of hydroxyl) with a molecular weight of 50,000 g / mol and a functionality of 15, and react for 2 hours. Continue to add 5.4g (0.04mol) dimethylol propionic acid to react for 3 hours. Cool down to normal temperature, add 10 g (0.099 mol) of neutralizing agent triethylamine, and stir for 10 minutes. Add 7.8g (0.02mol) diisooctyl sulfonate sodium succinate to prepare hyperbranched structure modified polyurethane polymer.

[0049] Continue to add 1422g deionized water, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com