Hydrophobically modified hyperbranched polymer and preparation method thereof

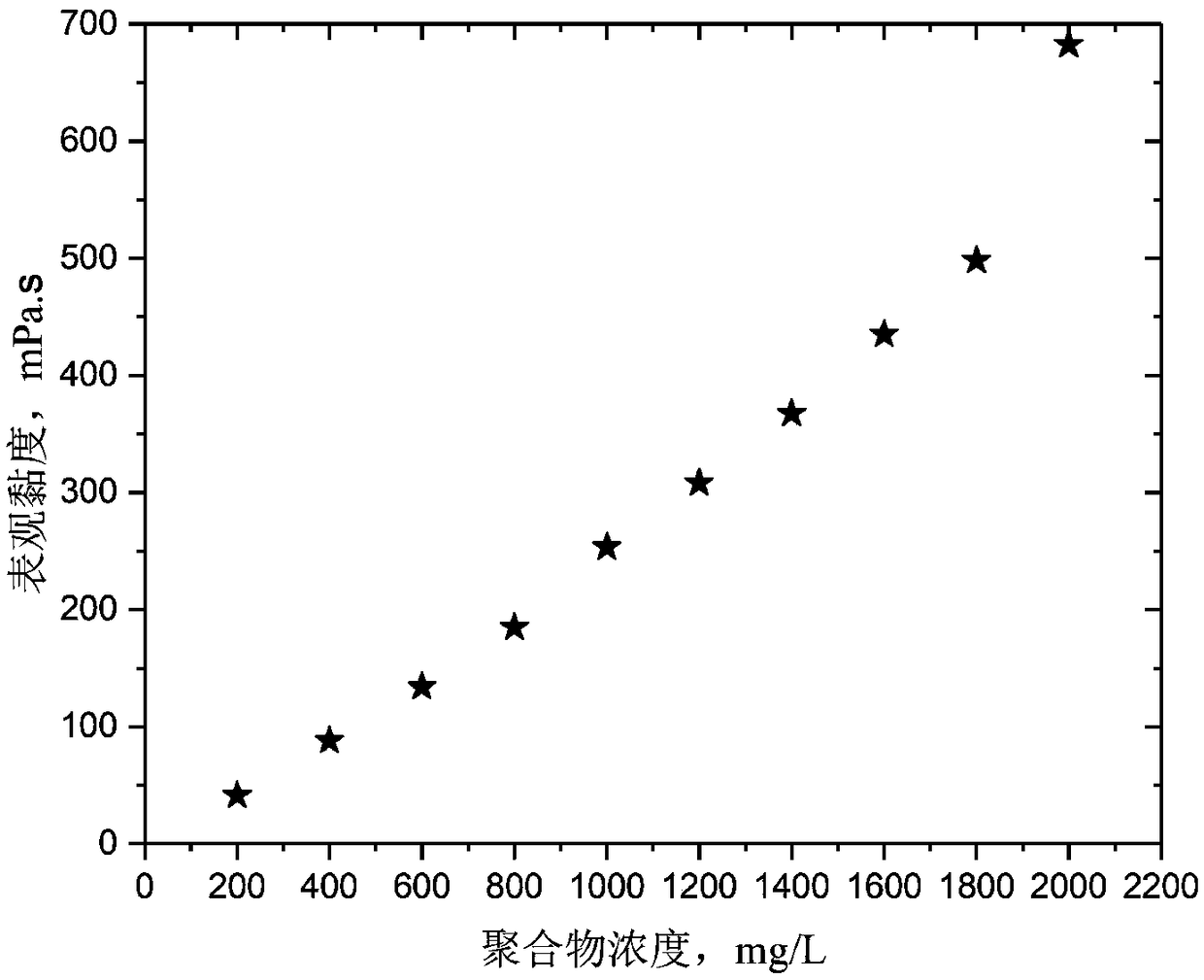

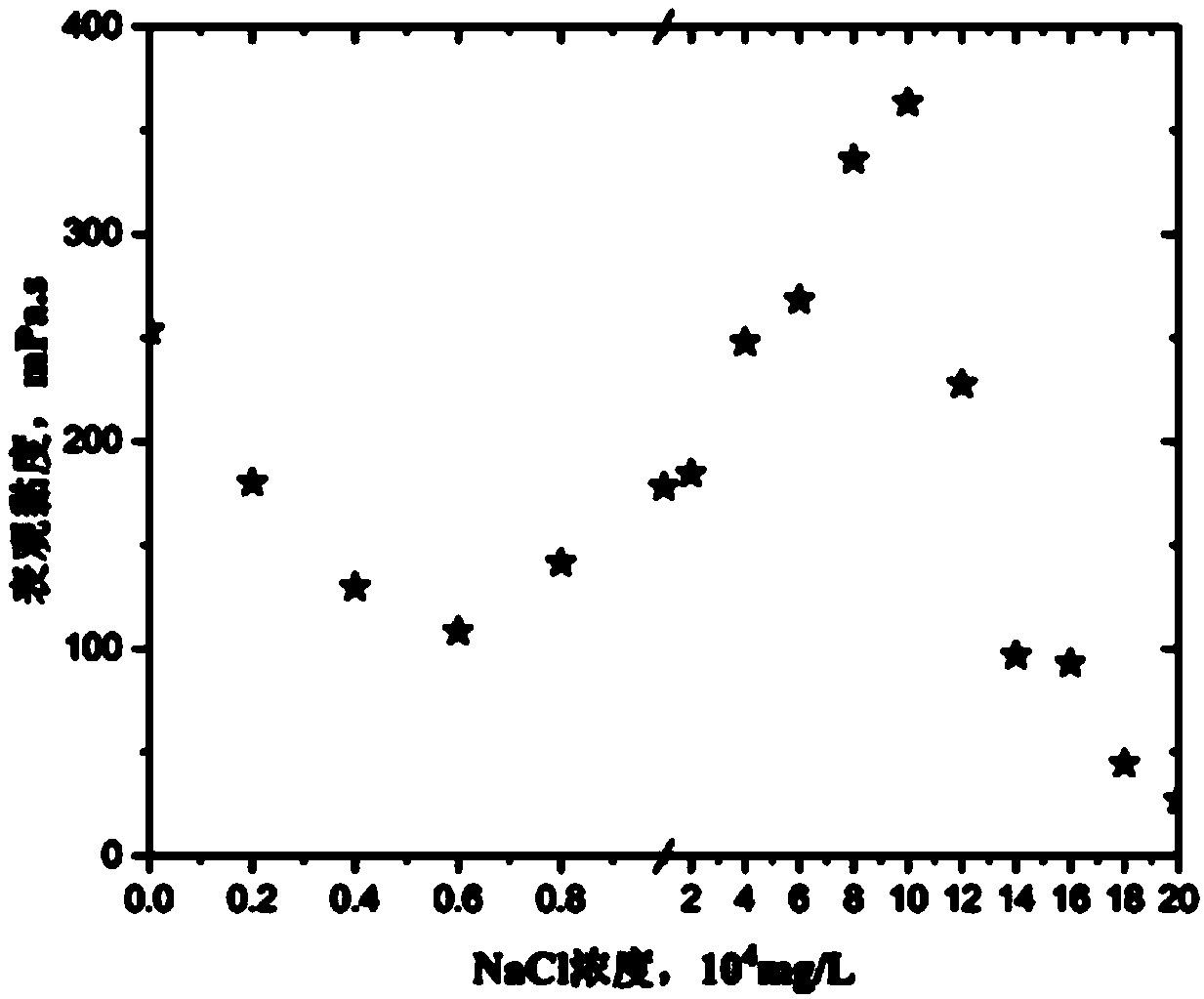

A hyperbranched polymer and hydrophobic modification technology, applied in the field of polymers, can solve the problem of difficulty in controlling the addition of divinyl or dipropylene monomers, low reactivity ratio of N-vinyl-2-pyrrolidone, polymer Viscosity increase and salt resistance are not ideal, to achieve the effect of true and reliable principle, excellent viscosity increase and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Such as figure 1 Shown, the preparation method of the hydrophobically modified hyperbranched polymer that the embodiment of the present invention provides comprises the following steps:

[0029] S101: Add acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and hyperbranched modified monomer in deionized water, stir evenly, adjust the pH value to 7 with sodium hydroxide, and then add hydrophobic monomer N-benzyl-N-alkyl (meth)acrylamide and surfactant sodium lauryl sulfate are magnetically stirred until the solution is clear and transparent;

[0030] S102: remove the dissolved oxygen in the water with inert gas for 15 minutes;

[0031] S103: Add the photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, place the reaction system under the photoinitiator to react for 3-5 hours, and the reaction temperature is 10-30 °C, a white colloid is obtained, which is a hydrophobically modified hyperbranched polymer.

[0032] In a preferred embodiment...

Embodiment 1

[0036] Weigh 10g of acrylamide, 2.5g of acrylic acid, 0.01g of hyperbranched modified monomer, add distilled water and stir evenly, and adjust the pH value to 7; add 0.2g of N-benzyl-N-dodecylmethacrylamide and 0.7g Sodium lauryl sulfate, add a certain amount of distilled water again, make solution quality reach 50g, stir until solution is clear and transparent; Logical nitrogen gas 15min, remove the dissolved oxygen in water; Add initiator Irgacure2959 (0.016wt% of total monomer mass), Placed under the photoinitiator, reacted for 4h.

Embodiment 2

[0038] Weigh 9.9g acrylamide, 1.6g acrylic acid, 1.0g 2-acrylamide-2-methylpropanesulfonic acid, 0.01g hyperbranched modified monomer, add distilled water and stir evenly, adjust the pH value to 7; add 0.2gN- Benzyl-N-dodecylmethacrylamide and 0.7g sodium lauryl sulfate, add a certain amount of distilled water to make the solution quality reach 50g, stir until the solution is clear and transparent; blow nitrogen gas for 15min to remove dissolved oxygen in the water ; Add the initiator Irgacure2959 (0.016wt% of the total mass of the monomer), place it under the photoinitiator, and react for 4h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com