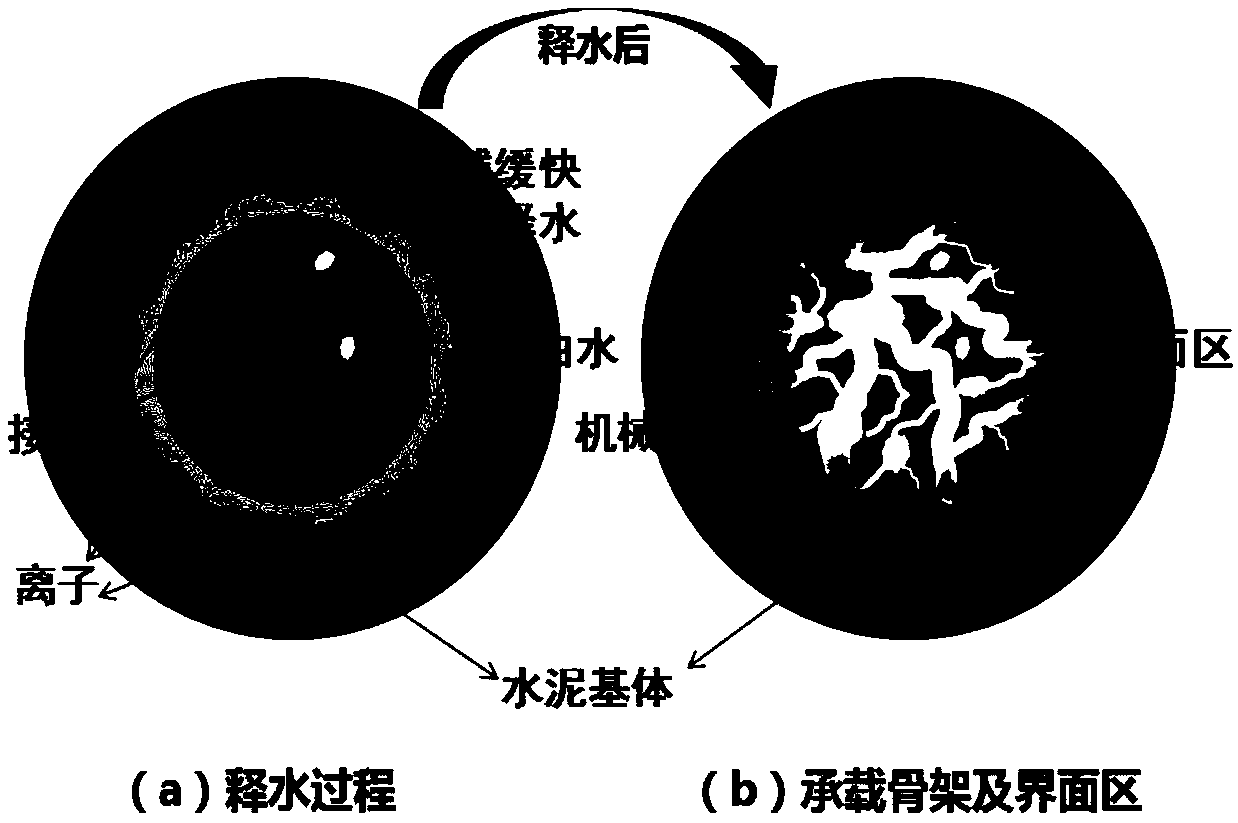

Preparation method of concrete having no strength negative effect and high internal curing efficiency

A concrete and negative technology, which is applied in the field of preparation of concrete with no negative impact on strength and high internal maintenance efficiency, can solve the problems of reduced concrete strength, low water absorption rate, and difficulty in ensuring internal maintenance efficiency, so as to achieve efficient utilization, eliminate negative impact, Avoid the effect of early free water release too quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Mix clay powder and pore regulator (carbon powder with an average particle size of 100 μm and polypropylene fiber with a diameter of 30 μm) with water to form a raw dough (both carbon powder and polypropylene fiber account for 15% of the mass of the raw dough, Water accounts for 20% of the mass of the raw dough), preheated and dried, calcined in the range of 800-1200 ° C for 1 h, and pulverized to obtain a porous rigid PM skeleton with high strength, high connectivity, and hierarchical pore structure (average particle size is 5μm-10mm);

[0033] 2) Soak the PM skeleton prepared in step 1) in a 2mol / L NaOH solution for 72h, wash it with fresh water, soak it in a silane coupling agent solution with a mass concentration of 1% for 24h, and dry it to obtain a surface modification. Sexually porous PM skeleton;

[0034] 3) Using the conventional sol-gel method, the monomer (acrylic acid), crosslinking agent (N,N'-methylenebisacrylamide, the dosage is 0.06% of the monomer m...

Embodiment 2

[0037] 1) Mix shale powder and pore regulator (EPS foam particles with an average particle size of 500 μm, waste paper plant fibers with a diameter of 50 μm) and water to form a raw material mass (carbon powder and polypropylene fiber account for the mass of the raw material mass respectively 10% and 40%, water accounts for 20% of the mass of the raw dough), preheated and dried, calcined in the range of 800-1200 ° C for 2 hours, and crushed to obtain porous rigidity with high strength, high connectivity and hierarchical pore structure PM skeleton (average particle size 4mm-20mm);

[0038] 2) Soak the PM skeleton prepared in step 1) in a 1mol / L NaOH solution for 72h, wash it with fresh water, soak it in a silane coupling agent solution with a mass concentration of 1.5% for 24h, and dry it to obtain a surface modification. Sexually porous PM skeleton;

[0039] 3) Using the conventional sol-gel method, the monomer (acrylic acid and acrylamide, the ratio of the two is 4:6), the c...

Embodiment 3

[0042] 1) Mix shale powder and pore regulator (carbon powder with an average particle size of 50nm and polypropylene fiber with a diameter of 15μm) with water to form a raw material mass (carbon powder and polypropylene fiber account for 20% of the mass of the raw material mass respectively and 10%, water accounts for 20% of the mass of the raw dough), preheated and dried, calcined in the range of 800-1200 ° C for 2 hours, and pulverized to obtain a porous rigid PM skeleton with high strength, high connectivity, and hierarchical pore structure ( The average particle size is 5μm-4mm);

[0043] 2) Soak the PM skeleton prepared in step 1) in a 4mol / L NaOH solution for 72h, wash it with fresh water, soak it in a silane coupling agent solution with a mass concentration of 0.5% for 24h, and dry it to obtain a surface modification. Sexually porous PM skeleton;

[0044] 3) Using the conventional sol-gel method, the monomer (acrylamide), crosslinking agent (N,N'-methylenebisacrylamide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com