Tin-doped nickel oxide-tin dioxide composite nanocrystalline film and preparation method thereof

A technology of tin dioxide and nickel oxide, applied in the coating and other directions, can solve the problems of affecting the visible light transmittance of the faded nickel oxide film, difficult to obtain transparent nickel oxide materials, and low electrochromic performance of the nickel oxide film, etc. Electrochromic properties, enhancing electronic conductivity, solving the effect of low optical modulation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a tin-doped nickel oxide-tin dioxide composite nanocrystalline film, which is characterized in that the specific steps are as follows:

[0032] Step 1, preparing composite sol C containing Sn-Ni elements

[0033] Step 1.1, preparing Ni-containing sol A: the preparation process is as follows: nickel acetate is added to anhydrous methanol, fully stirred at room temperature until clarified, then an appropriate amount of acrylic acid is added, and the stirring is continued for 2 hours to obtain dark green clear sol A;

[0034] Step 1.2, preparation of Sn-containing sol B: the preparation process is to mix tin tetrachloride and acetylacetone, and stir at 45°C to 60°C for 15 minutes, then add acetic anhydride to it, and stir at 45°C for 15 minutes Minutes, cooled to room temperature, finally added an appropriate amount of ethanol, continued to stir for 20 minutes to obtain a clear sol B;

[0035] In step 1.3, mix sol...

Embodiment 1

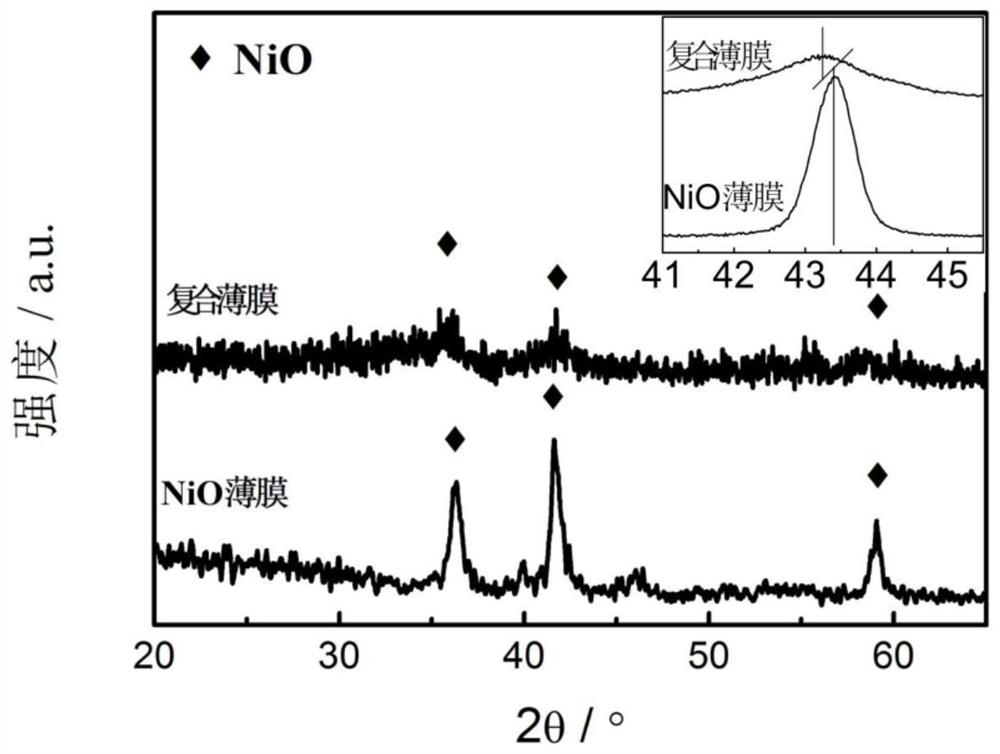

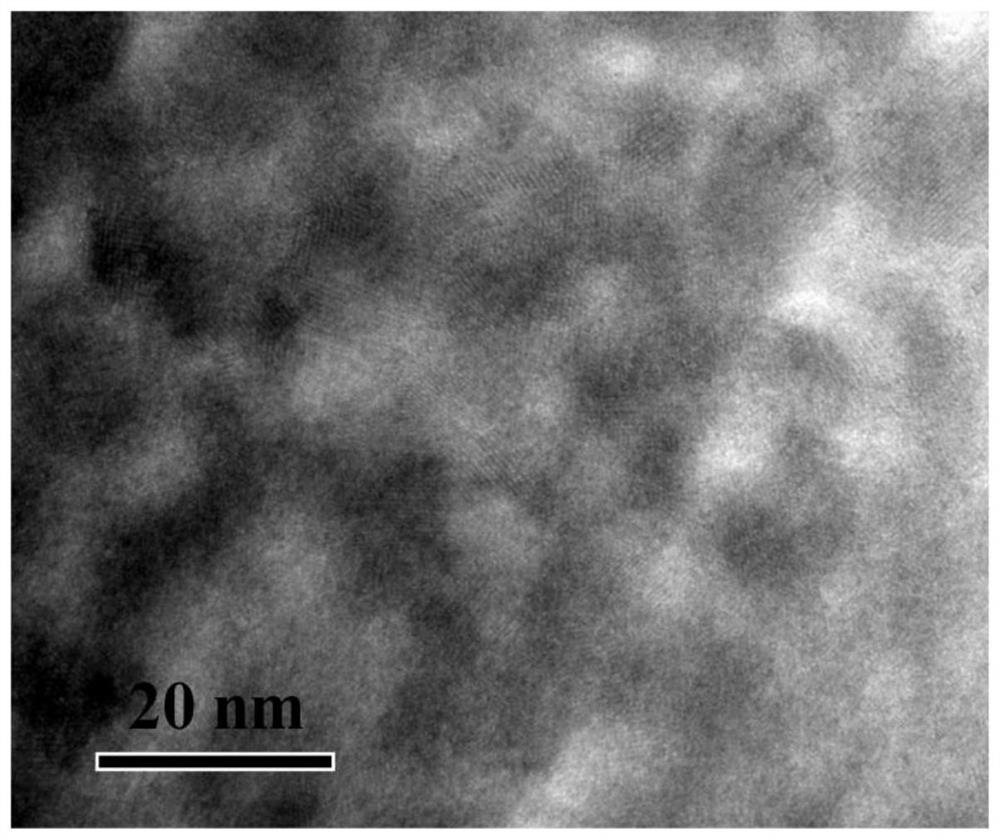

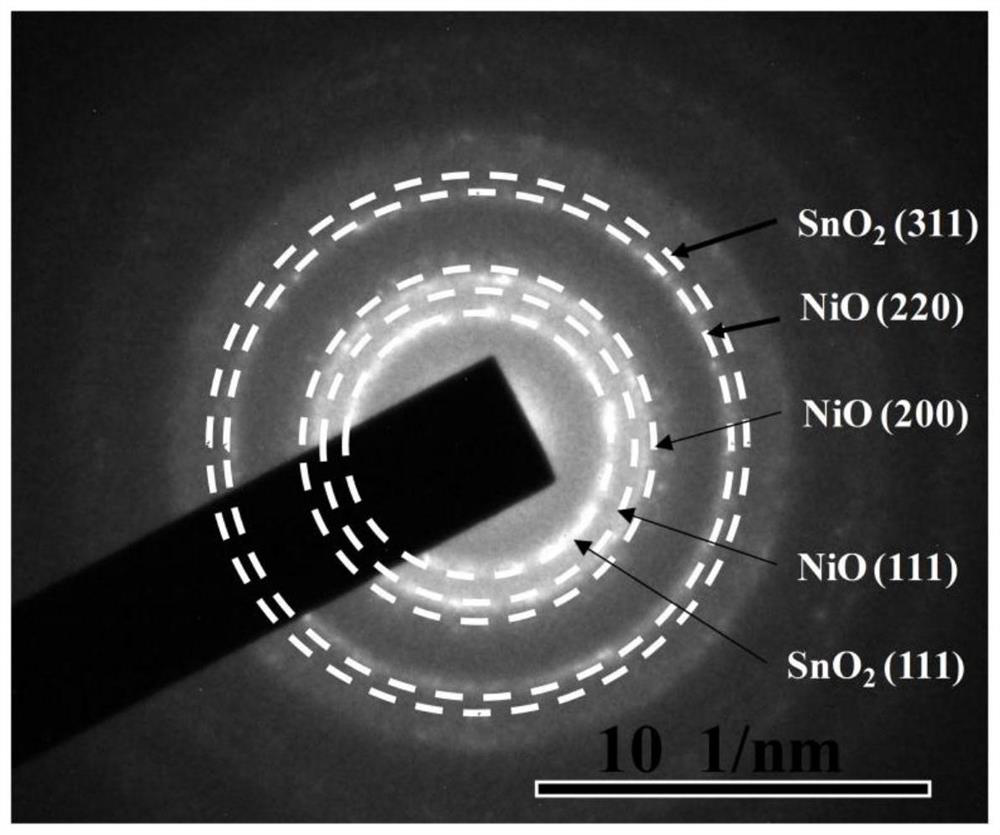

[0049] A tin-doped nickel oxide-tin dioxide composite nanocrystalline electrochromic film, which has the following structural features: the average grain size of tin-doped nickel oxide is 60 nanometers, the average grain size of tin dioxide is 5 nanometers, and the film thickness to 300 nm.

[0050] The preparation method of the composite film with the above structural characteristics, the concrete steps are as follows:

[0051] First, a composite sol containing Ni and Sn elements is prepared. The process is as follows:

[0052] Mix 4.604 g of nickel acetate with 30 ml of anhydrous methanol, stir well at room temperature until clear, then add 4 ml of acrylic acid, and continue stirring for 2 hours to obtain dark green clear sol A.

[0053] 1.622 grams of tin tetrachloride was mixed with 3.113 grams of acetylacetone, and stirred at 45°C for 15 minutes, then 0.698 grams of acetic anhydride was added thereto, and stirred at 45°C for 15 minutes, cooled to room temperature, and f...

Embodiment 2

[0061] A tin-doped nickel oxide-tin dioxide composite nanocrystalline electrochromic film, which has the following structural features: the average grain size of tin-doped nickel oxide is 50 nanometers, the average grain size of tin dioxide is 8 nanometers, and the film thickness for 350 nm.

[0062] The preparation method of the composite film with the above structural characteristics, the concrete steps are as follows:

[0063] First, a composite sol containing Ni and Sn elements is prepared. The process is as follows:

[0064] Mix 4.604 g of nickel acetate with 30 ml of anhydrous methanol, stir well at room temperature until clear, then add 4 ml of acrylic acid, and continue stirring for 2 hours to obtain dark green clear sol A.

[0065] 1.816 grams of tin tetrachloride was mixed with 3.487 grams of acetylacetone, and stirred at 48°C for 15 minutes, then 0.783 grams of acetic anhydride was added thereto, and stirred at 45°C for 15 minutes, cooled to room temperature, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com