Preparation method of glass ceramics based on modified wollastonite

A technology of glass-ceramics and wollastonite, which is applied in the field of preparation of glass-ceramics based on modified wollastonite, can solve problems such as poor material properties, achieve waste utilization, strong activity, and accelerate nucleation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method based on modified wollastonite glass-ceramics of the present embodiment, comprises the following steps:

[0027] Step 1: Weigh the following raw materials corresponding to the weight percentage for later use: 32% of flotation tailings of lead-zinc ore, 6% of oolitic chlorite, 3% of palm fiber, 26% of phillipsite, 14% of modified wollastonite, rare earth minerals 1%;

[0028] Step 2: Mix the raw materials in step 1 evenly and put them into a corundum crucible for smelting, then put them into a mold for casting, then anneal, and then cool to room temperature at 25°C / min to obtain the present invention. Modified wollastonite glass-ceramic.

[0029] The chemical composition weight percent content of the lead-zinc ore flotation tailings of the present embodiment is SiO 2 52%, Al 2 o 3 12%, MgO 1.2-2.2%, Fe 2 o 3 2%, CaO 0.5%, organic components 6%.

[0030] The palm fiber of the present embodiment is soaked in alkaline water with a mass ...

Embodiment 2

[0037] A kind of preparation method based on modified wollastonite glass-ceramics of the present embodiment, comprises the following steps:

[0038] Step 1. Weigh the following raw materials corresponding to the weight percentage for later use: 38% of flotation tailings of lead-zinc ore, 8% of oolitic chlorite, 5% of palm fiber, 30% of phillipsite, 20% of modified wollastonite, and rare earth minerals 3%;

[0039] Step 2: Mix the raw materials in step 1 evenly and put them into a corundum crucible for smelting, then put them into a mold for casting, then anneal, and then cool to room temperature at 35°C / min. Modified wollastonite glass-ceramic.

[0040] The chemical composition weight percent content of the lead-zinc ore flotation tailings of the present embodiment is SiO 2 58%, Al 2 o 3 18%, MgO 2.2%, Fe 2 o 3 6%, CaO 1.5%, organic components 10%.

[0041] The palm fiber in this embodiment is soaked in alkaline water with a mass concentration of 20% for 3 hours and t...

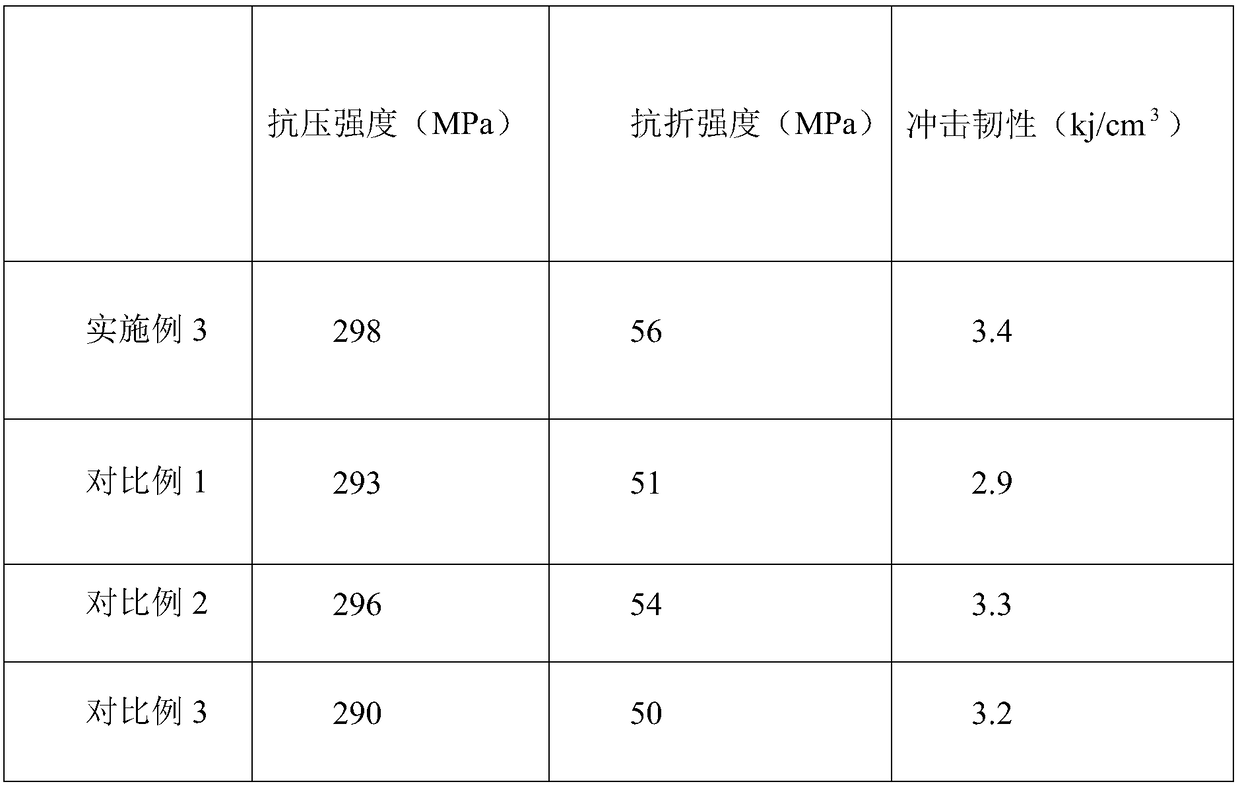

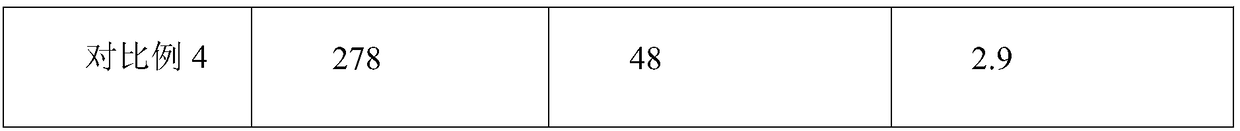

Embodiment 3

[0048] A kind of preparation method based on modified wollastonite glass-ceramics of the present embodiment, comprises the following steps:

[0049] Step 1. Weigh the following raw materials corresponding to the weight percentage for later use: 35% of flotation tailings of lead-zinc ore, 7% of oolitic chlorite, 4% of palm fiber, 27% of phillipsite, 17% of modified wollastonite, rare earth mineral 2%;

[0050] Step 2: Mix the raw materials in step 1 evenly and put them into a corundum crucible for smelting, then put them into a mold for casting, then anneal, and then cool to room temperature at 30°C / min to obtain the present invention. Modified wollastonite glass-ceramic.

[0051] The chemical composition weight percent content of the lead-zinc ore flotation tailings of the present embodiment is SiO 2 55%, Al 2 o 3 15%, MgO 1.7%, Fe 2 o 3 4%, CaO 1%, organic components 8%.

[0052] The palm fiber of this embodiment is that the mass concentration is 15% alkaline water so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com