A method for in situ nondestructive exfoliation of quantum dots

A quantum dot and in-situ technology, which is applied in the field of in-situ non-destructive peeling of quantum dots, can solve the problems of material damage, uneconomical, pollution, etc., and achieve the effects of low cost, wide applicability, and reducing the impact of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

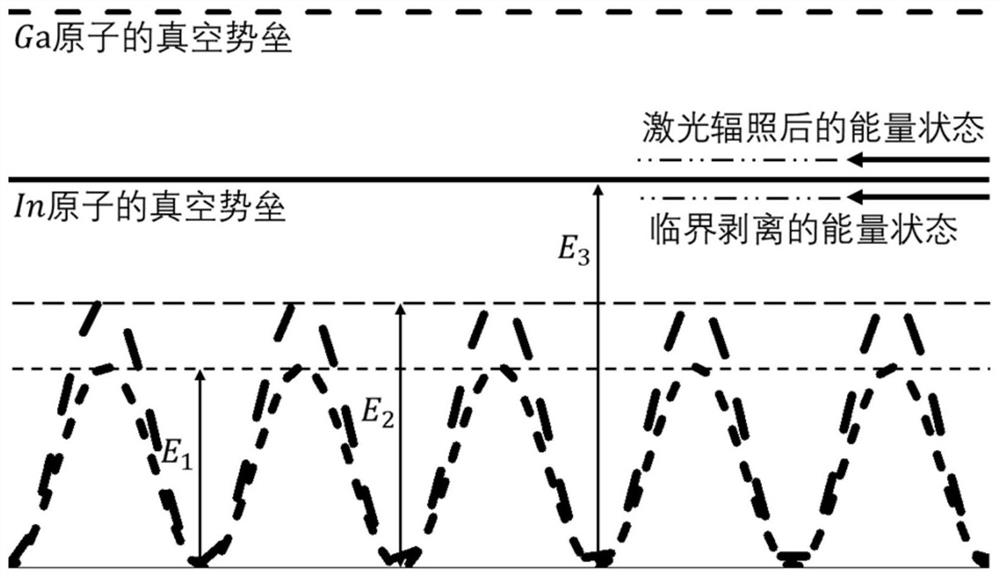

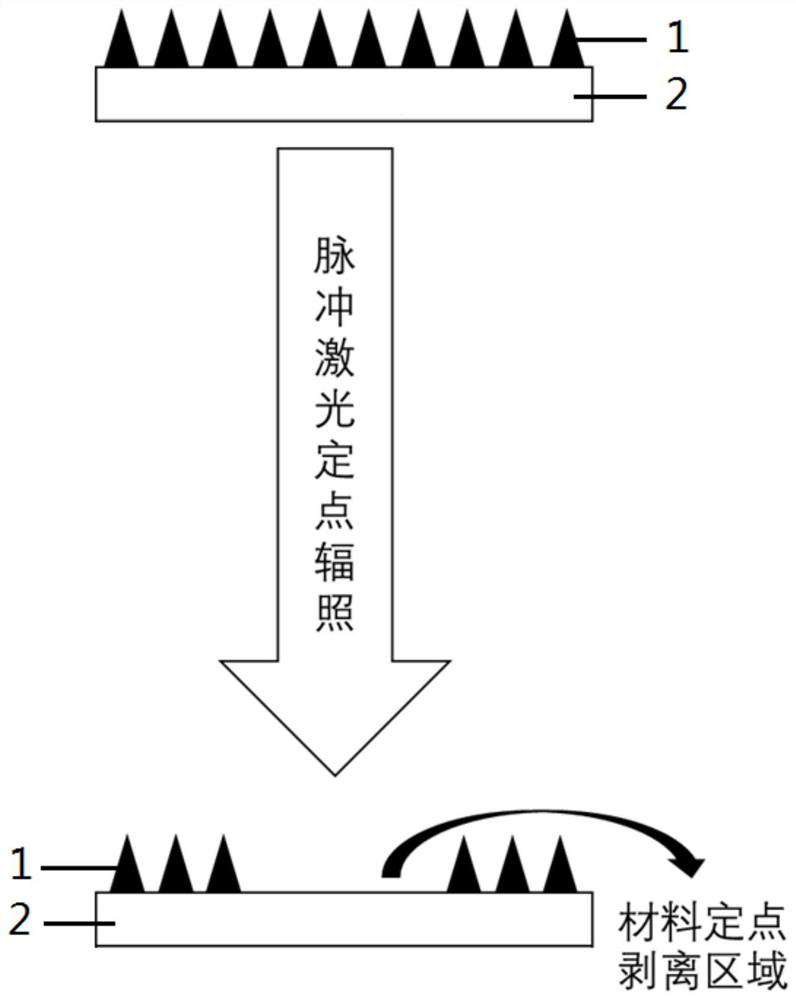

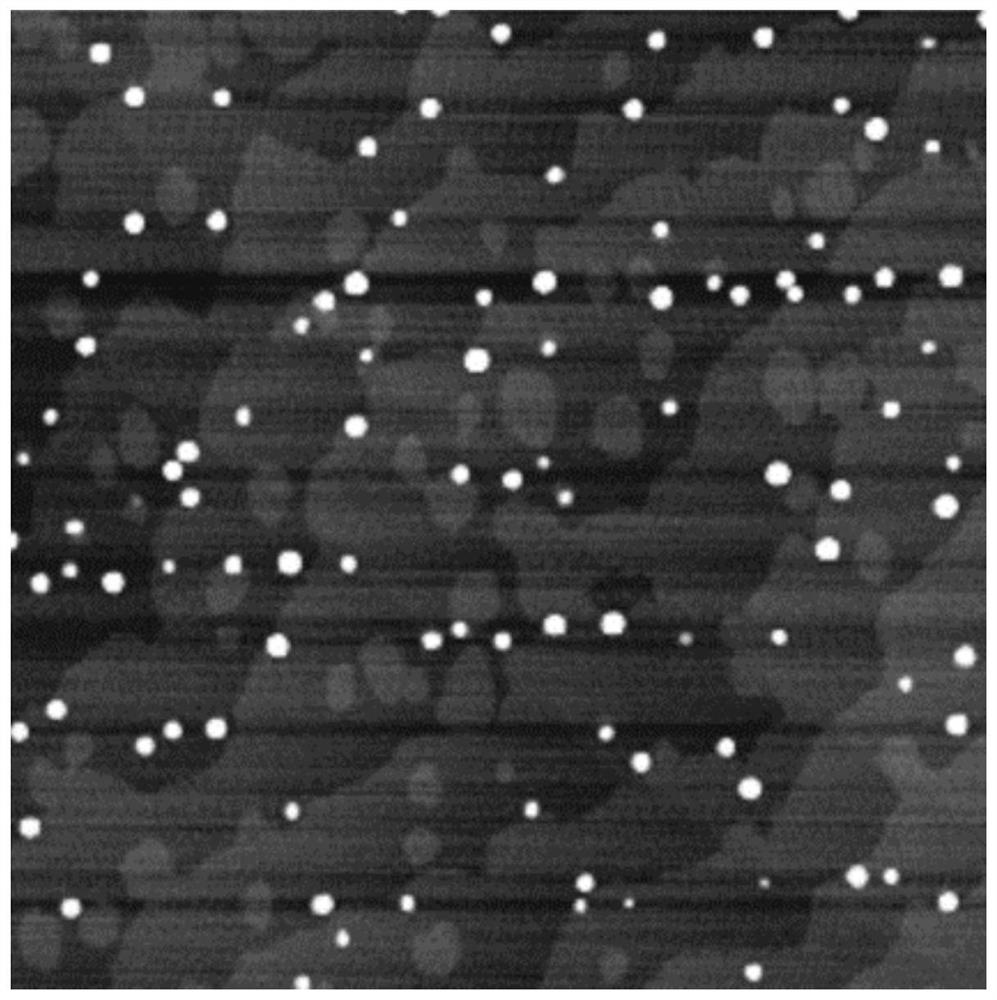

[0034] The sample of InAs / GaAs quantum dots to be stripped (that is, the InAs quantum dots are distributed on the surface of the substrate formed by the GaAs film) is heated to the critical desorption temperature of InAs under the premise of an As-rich atmosphere in the MBE growth chamber. In this embodiment, the arsenic pressure is set to 8.0×10 -7 Torr, the critical desorption temperature is 525°C. Such as image 3 As shown, the AFM test results of the quantum dot sample to be stripped indicate that a certain density of InAs quantum dots (white dots) have been successfully grown on the surface of the GaAs substrate.

[0035] Then a single pulse laser was introduced to irradiate the sample surface, where the laser wavelength was 355nm, the pulse width was 10ns, and the laser energy was 10mJ. The sample surface after laser irradiation is like Figure 4 As shown, I can see that the InAs quantum dots have been stripped clean (the white dots have disappeared), leaving only the flat...

Embodiment 2

[0039] The InAs quantum dots in the InAs / GaAs quantum dot samples were stripped according to the method of Example 1, the difference is that the arsenic pressure is set to 8.0×10 -6 Torr, the critical desorption temperature is 510℃, and the laser energy of the single pulse laser is 15mJ.

Embodiment 3

[0041] The InAs quantum dots in the InAs / GaAs quantum dot samples were stripped according to the method of Example 1, the difference is that the arsenic pressure is set to 8.0×10 -7 Torr, the critical desorption temperature is 530°C, and the laser energy of the single pulse laser is 20mJ.

[0042] In addition, according to the above method, you can also choose different quantum dot systems, such as InSb / AlSb quantum dots, InSb / GaSb quantum dots, InSb / AlAs quantum dots, InSb / GaAs quantum dots, InN / AlN quantum dots or InN / GaN quantum dots Dot system, the one before " / " is the quantum dot, and the one after " / " is the substrate material. In the quantum dot system, the quantum dots with lower vacuum energy barrier and lower bonding energy are stripped, and the specific critical desorption temperature is The settings and selection of pulse laser parameters are set according to the energy of the quantum dots to be stripped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com