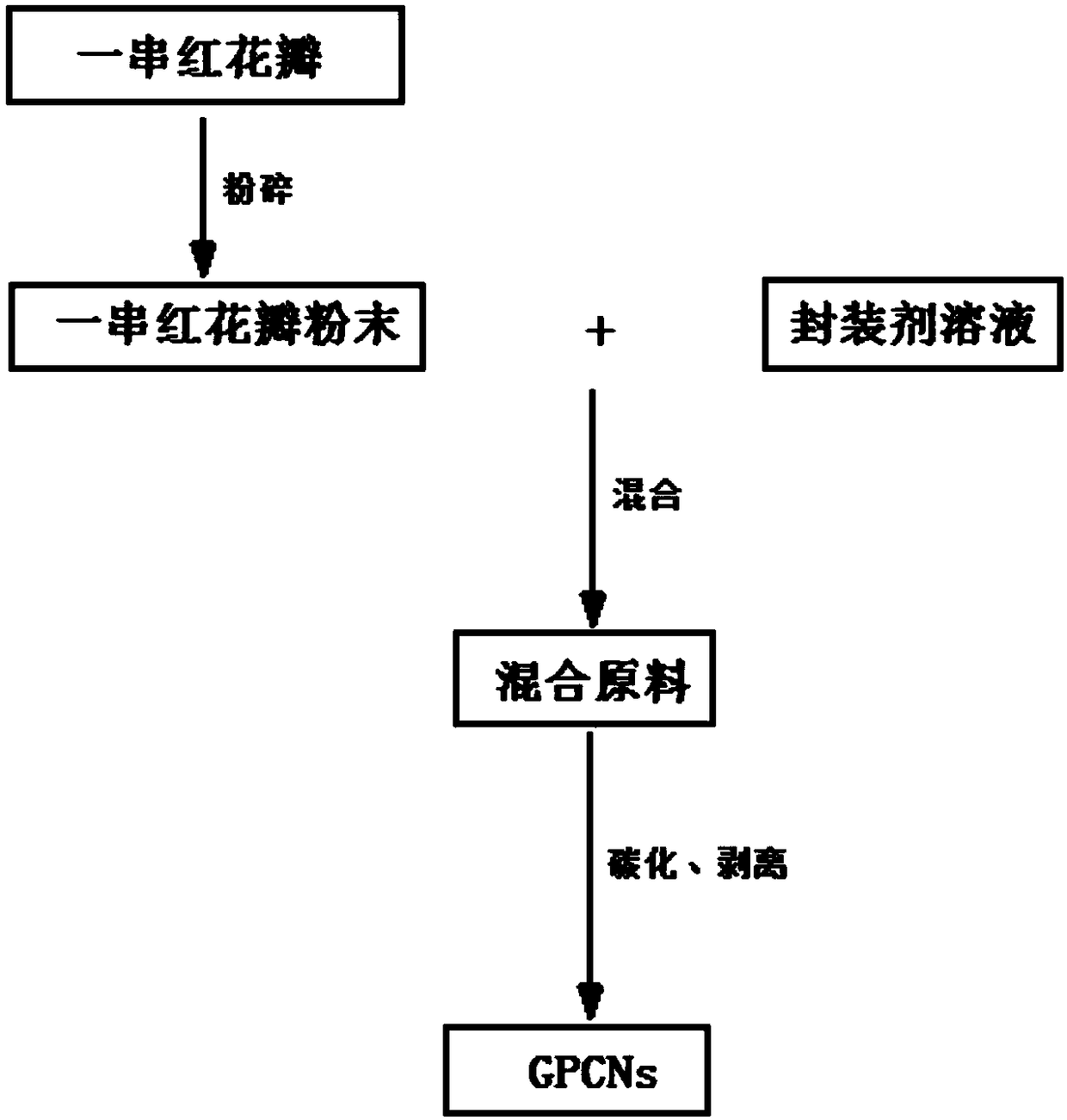

Salvia splendens petal-based porous graphene-like carbon nanosheets as well as preparation method and application thereof

A technology of graphene and porous carbon, applied in the direction of nano-carbon, hybrid capacitor electrodes, etc., can solve the problems of cumbersome preparation process, etc., and achieve the effect of simple operation, avoiding corrosion, and short ion transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Wash a string of red petals with clean water to remove impurities, and after drying, crush them to 80 mesh with a pulverizer. Take 5g of a string of red petals powder and 15g of NaCl solids, add them to 50ml of water and mix evenly, heat and evaporate the water to dryness to obtain a string of red petals encapsulated by NaCl. Next, after placing the encapsulated sample in a high-temperature tube furnace, the N 2 Under the protection of 5℃·min -1 Raise the temperature to 800°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with ultrapure water several times to NaCl. Finally, the product was dried to constant weight to obtain 1.01 g of a string of red petal-based graphene-like porous carbon nanosheets.

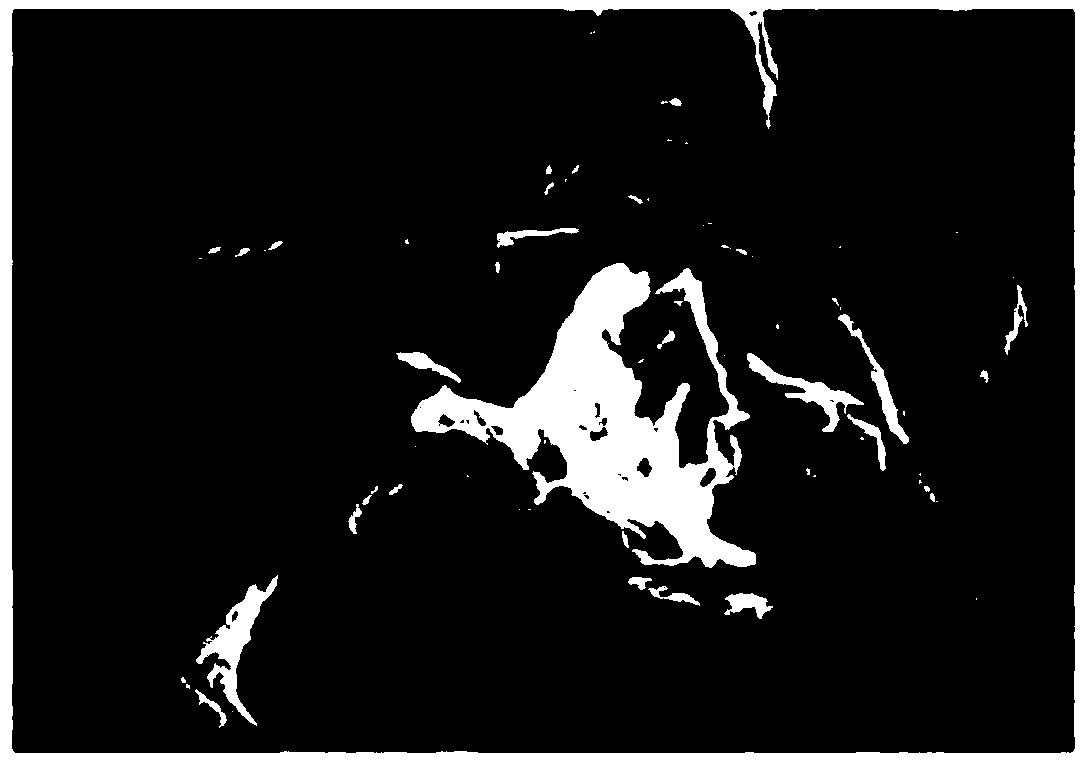

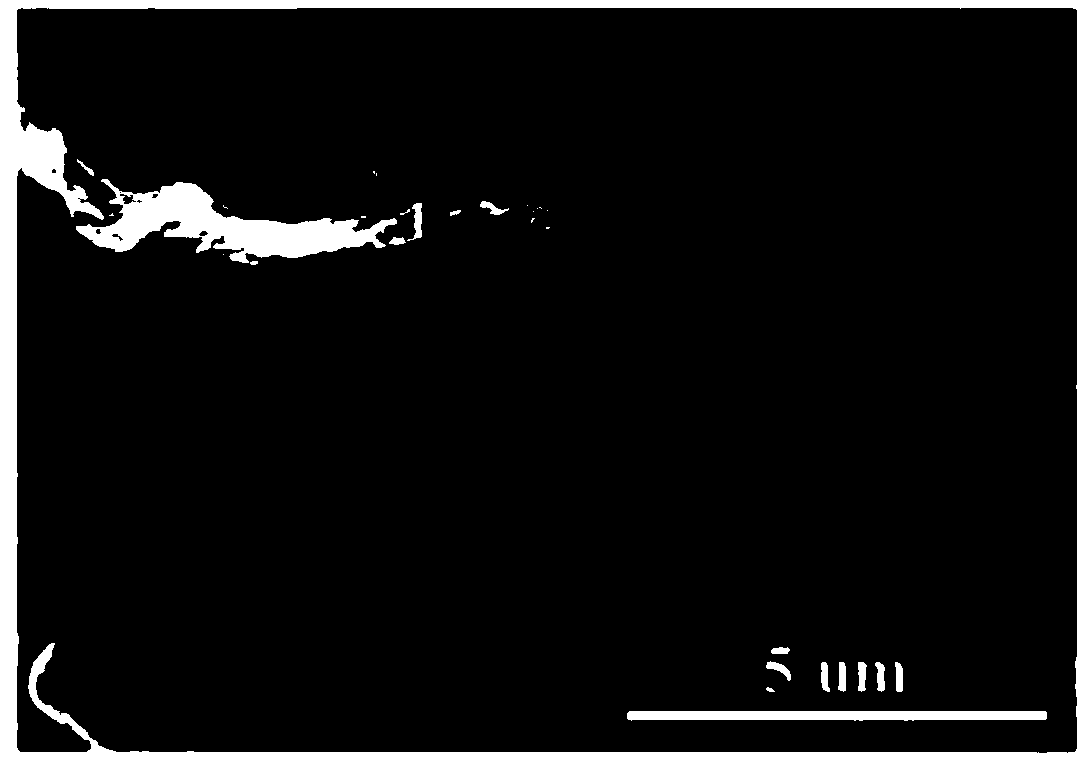

[0089] The prepared porous carbon nanosheets as figure 1 Shown has the graphene-like porous nanosheet structure, and the thickness of the prepared nanosheets is mostly concentrated in the range of 20-50nm; as f...

Embodiment 2

[0091] Wash a string of red petals with clean water to remove impurities, and after drying, crush them to 80 mesh with a pulverizer. Take 5g of a string of red petals powder and 15g of NaCl solids, add them to 50ml of water and mix evenly, heat and evaporate the water to dryness to obtain a string of red petals encapsulated by NaCl. Next, after placing the encapsulated sample in a high-temperature tube furnace, the N 2 Under the protection of 5℃·min -1 Raise the temperature to 700°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with ultrapure water several times to NaCl. Finally, the product was dried to constant weight to obtain 1.15 g of a string of red petal-based graphene-like porous carbon nanosheets.

[0092] When the prepared porous carbon nanosheets are used as electrode materials for supercapacitors, at 0.5A g -1 Under the current density of , the specific capacitance of graphene-like carbon nanosheets is 32...

Embodiment 3

[0094] Wash a string of red petals with clean water to remove impurities, and after drying, crush them to 80 mesh with a pulverizer. Take 5g of a string of red petals powder and 15g of NaCl solid and add them to 100ml of water to mix evenly, heat and evaporate the water to dryness to obtain a string of red petals encapsulated by NaCl. Next, after placing the encapsulated sample in a high-temperature tube furnace, the N 2 Under the protection of 5℃·min -1 Raise the temperature to 900°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with ultrapure water several times to NaCl. Finally, the product was dried to constant weight to obtain a string of red petal-based graphene-like porous carbon nanosheets of 0.83g

[0095] When the prepared porous carbon nanosheets are used as electrode materials for supercapacitors, at 0.5A g -1 The specific capacitance of graphene-like carbon nanosheets is 318F·g under the current density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com