Porcelain repair technology

A kind of porcelain and technical technology, applied in the field of porcelain restoration, can solve the problems of fragility, weak connection strength of mother embryo, brittle texture of repaired parts, etc., and achieve the effect of improving repair strength, wide applicability, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

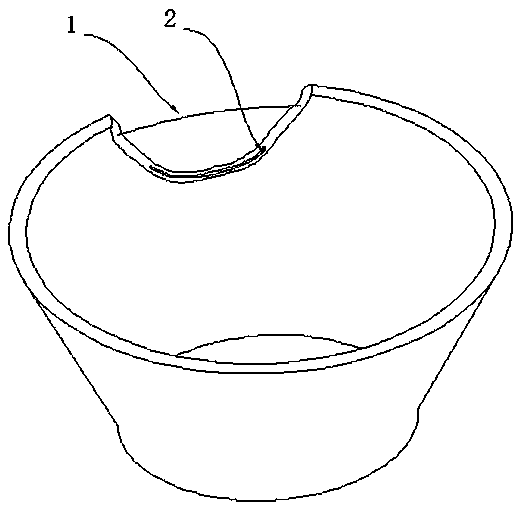

[0030] like figure 1 , shown in 2, a porcelain restoration technique, comprising the following steps:

[0031] (1) Clean the porcelain wound with clean water, and then dry it to avoid the impact of magazines on the connection between the tissue material and the mother embryo;

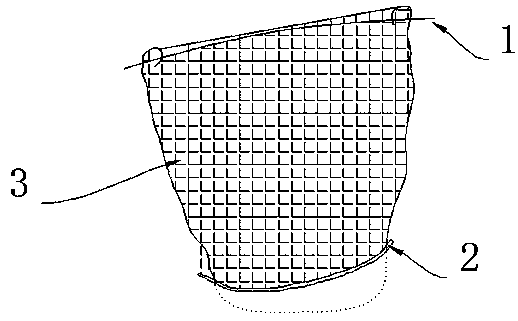

[0032] (2) Make a groove at the mother embryo of the porcelain wound. The groove is preferably a linear groove 2. The depth of the linear groove 2 is 1mm, whichever can fix the barbed wire 3, and drill a hole at a position as far away as possible and opposite to the groove. The fixing rod 1 is conducive to placing the barbed wire mesh 3 in a larger area in the wound. The fixing rod 1 does not exceed the edge of the porcelain wound, and there can be one or more rods, which can be horizontal or vertical, depending on the shape of the wound;

[0033] (3) Use scissors to cut out the barbed wire 3 in the shape of a porcelain wound. The hole diameter of the barbed wire 3 is 2mm. The size of the barbed wire 3...

Embodiment 2

[0038] (1) Clean the porcelain wound with clean water, and then dry it to avoid the impact of magazines on the connection between the tissue material and the mother embryo;

[0039] (2) Make a groove at the mother embryo of the porcelain wound. The groove is preferably a linear groove 2. The depth of the linear groove 2 is 0.8mm, whichever can fix the barbed wire 3, and drill holes at a position as far away as possible and opposite to the groove The fixing rod 1 is installed, which is beneficial to place the barbed wire mesh 3 in a larger area in the wound. The fixing rod 1 does not exceed the edge of the porcelain wound, and there can be one or more rods, which can be horizontal or vertical, depending on the shape of the wound;

[0040] (3) Use scissors to cut out the barbed wire 3 in the shape of a porcelain wound. The hole diameter of the barbed wire 3 is 5 mm. The size of the barbed wire 3 is basically such that it can cover most of the wound. The fixed rod 1 is wrapped ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com