Cap screwing-down assembly for bottle cap assembling machine

A cap assembly and assembly machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed processing quality, great impact on enterprise benefits, and high processing costs, achieving fast production speed and preventing lost steps. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

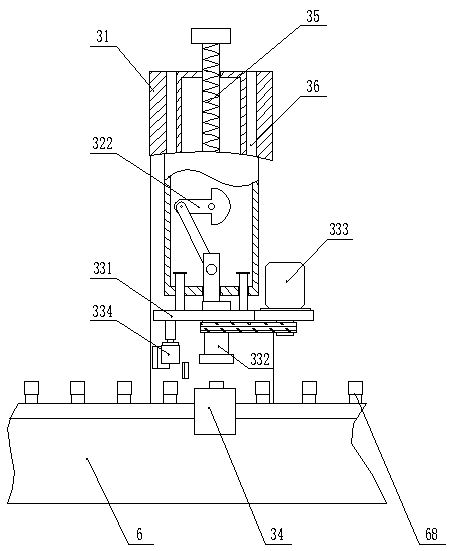

[0042] In order to make the purpose, technical solution and advantages of the present invention clearer, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

[0043] Of course, corresponding electrical hardware and corresponding control programs should also be matched before using the present invention. The cap screwing motor 321 , rotating motor 333 , base motor 63 and fixing motor 341 are respectively electrically connected to the main control chip, and the motors are controlled by corresponding programs.

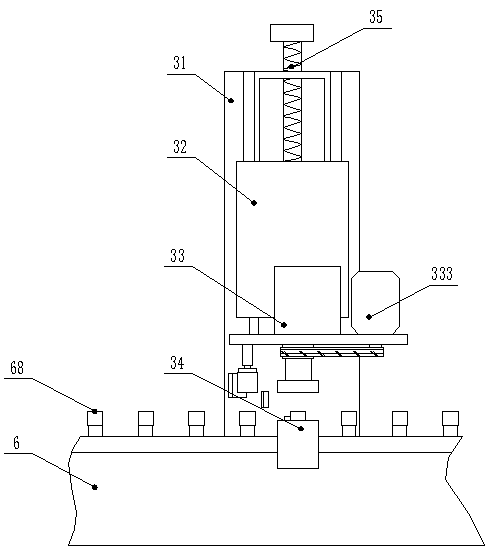

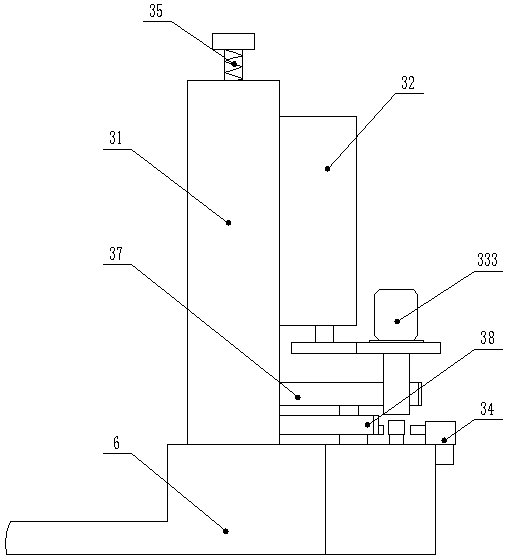

[0044]A cap screwing assembly of a bottle cap assembly machine, comprising: a cap screwing bracket 31, a cap screwing power box 32, a cap screwing head 33 and a fixing device 34; the screw cap screwing bracket 31 is vertically fixed on the base 6 of the bottle cap assembly machine , the capping power box 32 is installed on the capping bracket 31, the capping head 33 is installed under the capping power box 32, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com