Resistance projection-welding hybrid connecting method and system

A composite connection and resistance technology, used in resistance welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increasing the complexity of the manufacturing process, high cost, and increased quality, and achieve easy promotion and use, easy operation, and reduced surface area. The effect of indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

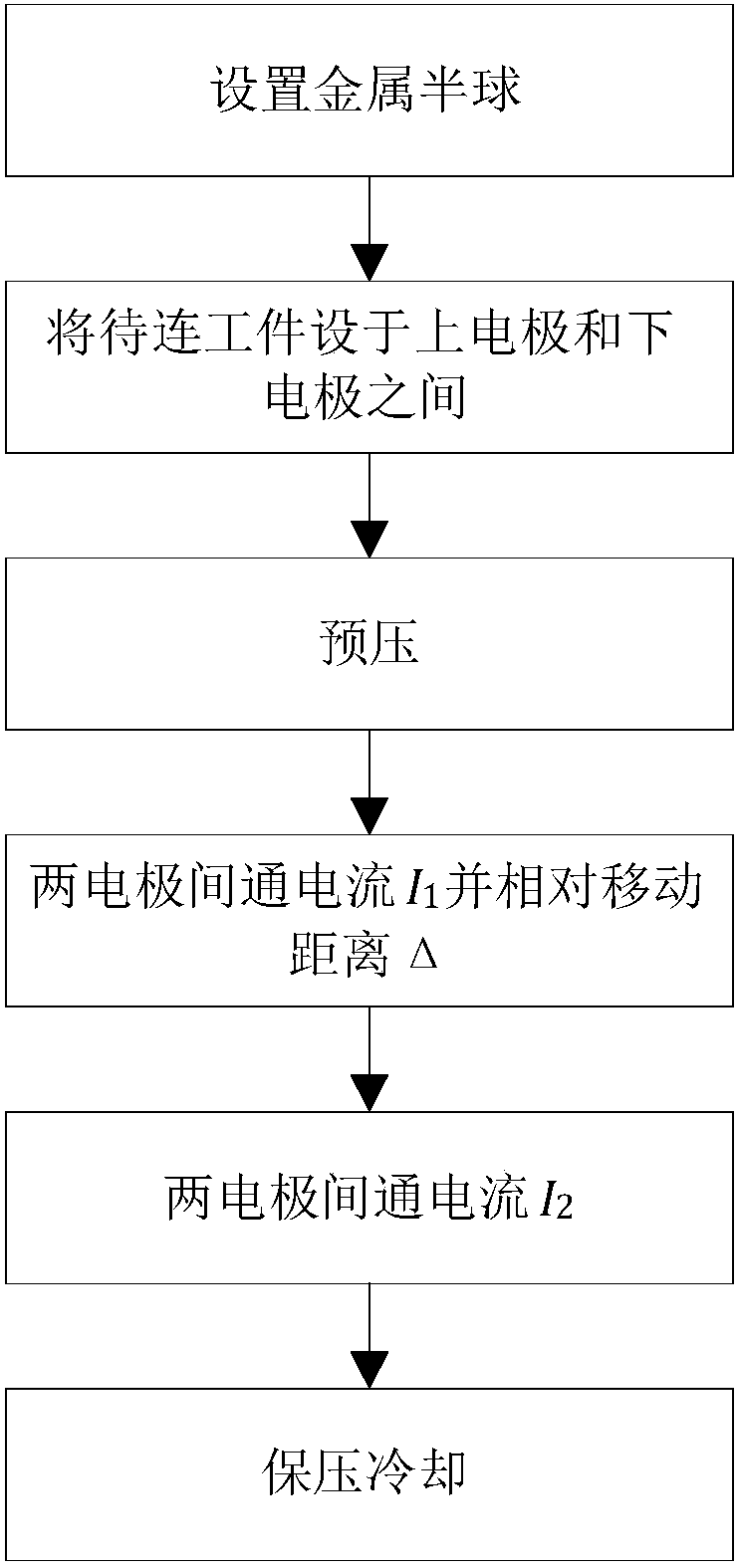

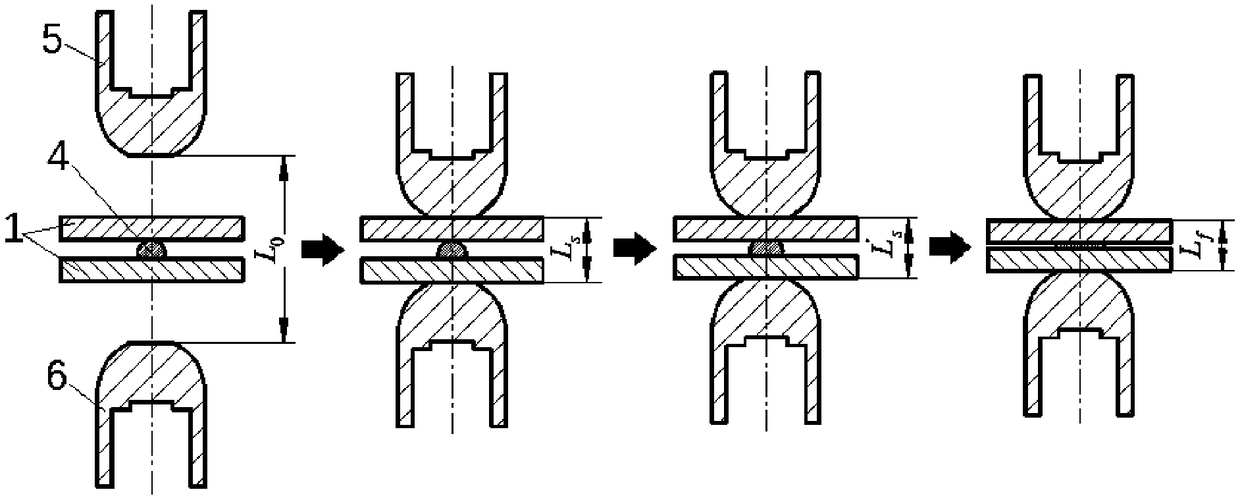

[0027] Such as figure 1 As shown, two workpieces 1 to be connected are connected, and the steps include:

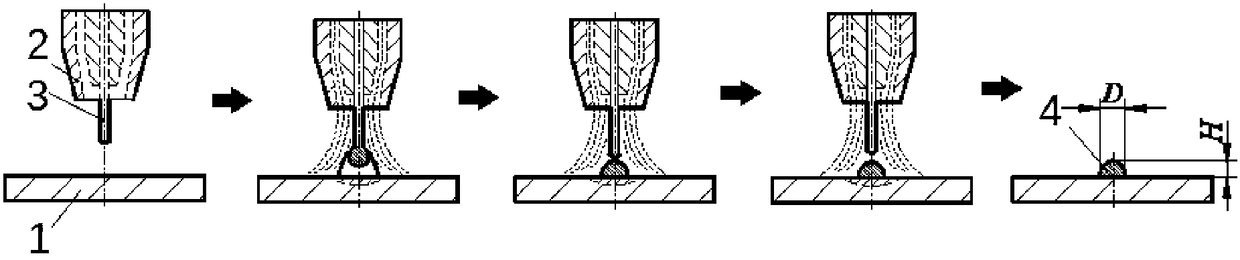

[0028] 1) Arranging a metal hemisphere 4 on the surface of one of the workpieces 1 to be joined by arc welding. Such as figure 2 shown, including the following specific steps:

[0029] 1.1) Move the arc welding torch 2 to a designated position on the upper part of the workpiece 1 to be connected, so that the welding wire 3 in the arc welding torch 2 is perpendicular to the surface of the workpiece 1 to be connected.

[0030] 1.2) Release the shielding gas, the shielding gas in the gas cylinder is released, forming a shielding gas atmosphere under the arc welding torch 2 .

[0031] 1.3) The arc welding torch 2 melts the welding wire 3 to form a metal hemisphere 4 on the surface of the workpiece 1 to be connected.

[0032] 1.4) Continue to release the protective gas to prevent the metal hemisphere 4 from oxidizing. The formed metal hemisphere 4 has a diameter D of 0.5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com