Preparation method and metal material for manufacturing metal mold through 3D printing

A metal mold and 3D printing technology, applied in the field of mold manufacturing, can solve the problems of unfavorable market competitiveness, long working time, low production efficiency, etc., and achieve the effect of low cost, high work efficiency, and small heat treatment deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present inventor is a kind of preparation method utilizing 3D printing to make metal mould, and it comprises the following operation steps:

[0022] The first step: first use the computer to draw the 3D model drawings of the products to be processed;

[0023] Step 2: Input the drawn 3D model drawings into the SLA 3D printer, and the SLA 3D printer will directly print out the resin mold, and then manually repair the mold to confirm the final shape of the mold, and perform mold clamping to confirm the accuracy of the mold ;

[0024] The third step: use the silicone mold turning technology to carry out the mold turning process on the resin mold to obtain a complete and accurate silicone mold;

[0025] The fourth step: Fill the metal material on the silicone mold, and then obtain the metal mold by heating and curing; among them, heating and curing means: put it in an oven at 100-150 degrees Celsius for 30-60 minutes to cure and shape, and take out the metal mold , and...

Embodiment 1

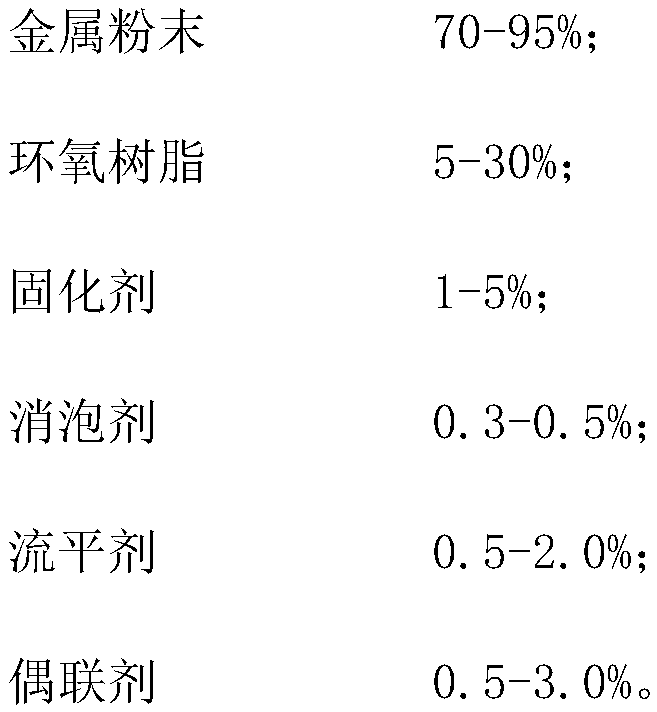

[0034] The mass percent of each component of described metal slurry is:

[0035]

[0036] Weigh each component, and then pre-disperse with a high-speed disperser at a speed of 500r / min for half an hour. Then use a three-roll machine to disperse, coarsely disperse 1-2 times, and finely disperse 3-5 times. After the end, you can get a usable metal slurry. The performance of the metal mold after the metal paste is completely cured meets the requirements of the EVA mold.

[0037] Temperature resistance 300 degrees Celsius, pressure resistance 90kg / cm2, plus good thermal conductivity.

[0038] Embodiment one:

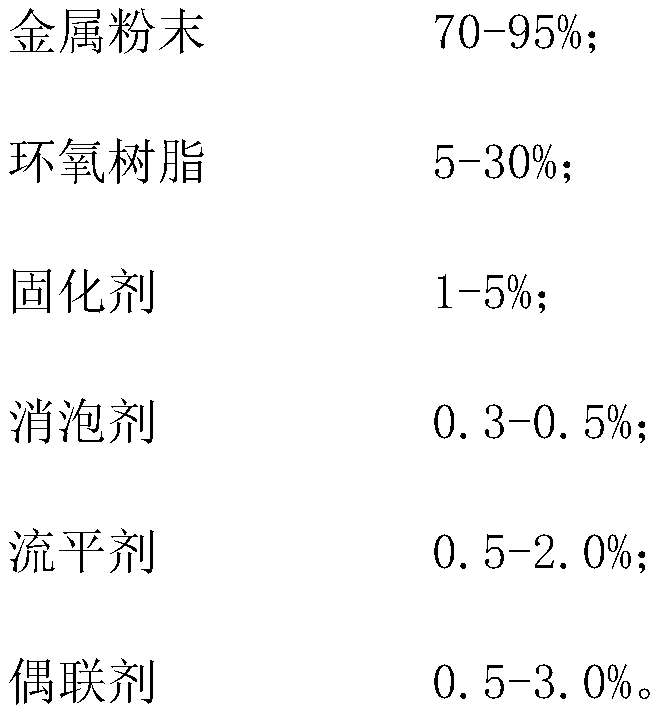

[0039] The mass percent of each component of described metal slurry is:

[0040]

[0041] Weigh each component, and then pre-disperse with a high-speed disperser at a speed of 500r / min for half an hour. Then use a three-roll machine to disperse, coarsely disperse 1-2 times, and finely disperse 3-5 times. After the end, you can get a usable metal slurry. The perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com