Nano gelatin/polymer composite fiber belt preparation method based on seawater uranium extraction

A composite fiber and polymer technology, applied in the direction of animal fiber, fiber treatment, alkali metal compounds, etc., to achieve the effect of low cost, good hydraulic performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

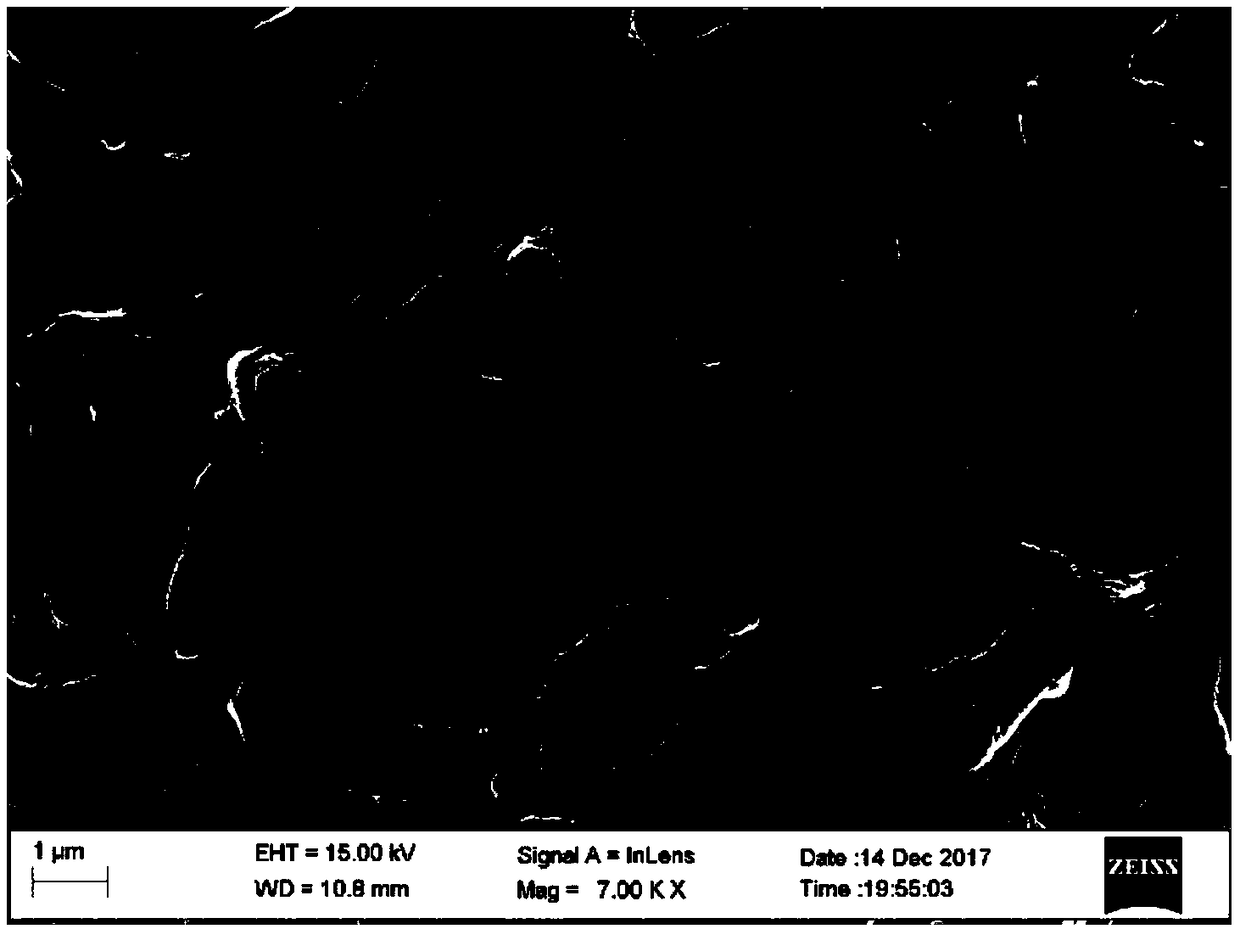

Image

Examples

Embodiment 1

[0036] A preparation method of nano-gelatin / polymer composite fiber tape based on the extraction of uranium from seawater, comprising the following steps:

[0037] Step 1, preparation of nano-gelatin / polymer fiber tape: take 4g of gelatin and dissolve it in 90wt% glacial acetic acid, stir magnetically at 60°C for 2h to obtain a gelatin solution with a mass fraction of 8%; weigh 5g of polyvinyl alcohol and dissolve it in Dissolve in distilled water to obtain a polyvinyl alcohol solution with a mass fraction of 5%, and then mix the two solutions evenly at a ratio of 1:9 by weight to obtain a spinning solution; extract the prepared electrospinning solution with a syringe, Fix the syringe on the electrospinning device, control the high-voltage power supply voltage to 10kv, the flow rate of the electrospinning solution to 0.3mL / h, the distance between the nozzle of the syringe needle and the collection screen to 6cm, and the spinning ambient temperature to 25 ℃, the inner diameter ...

Embodiment 2

[0040] A preparation method of nano gelatin / polymer composite fiber tape based on seawater extracting uranium, comprising the following steps:

[0041] Step 1, preparation of nano-gelatin / polymer fiber tape: take 6g of gelatin and dissolve it in 90wt% glacial acetic acid, stir magnetically at 60°C for 2h to obtain a gelatin solution with a mass fraction of 12%; weigh 8g of polyacrylamide and dissolve it in Dissolve in distilled water to obtain a polyacrylamide solution with a mass fraction of 8%, and then mix the two solutions evenly at a ratio of 2:8 by weight to obtain a spinning solution; extract the prepared electrospinning solution with a syringe, Fix the syringe on the electrospinning device, control the high-voltage power supply voltage to 15kv, the flow rate of the electrospinning solution to 0.6mL / h, the distance between the nozzle of the syringe needle and the collection screen to 8cm, and the spinning ambient temperature to 30 ℃, the inner diameter of the spinneret ...

Embodiment 3

[0044] A preparation method of nano gelatin / polymer composite fiber tape based on seawater extracting uranium, comprising the following steps:

[0045] Step 1, preparation of nano-gelatin / polymer fiber tape: take 8g of gelatin and dissolve it in 90wt% glacial acetic acid, stir magnetically at 60°C for 2h to obtain a gelatin solution with a mass fraction of 16%; weigh 10g of polyvinylpyrrolidone and dissolve it in Dissolve in distilled water to obtain a polyvinylpyrrolidone solution with a mass fraction of 10%, and then mix the two solutions uniformly in a ratio of 3:7 by weight to obtain a spinning solution; extract the prepared electrospinning solution with a syringe, Fix the syringe on the electrospinning device, control the high-voltage power supply voltage to 20kv, the flow rate of the electrospinning solution to 0.9mL / h, the distance between the nozzle of the syringe needle and the collection screen to 10cm, and the spinning ambient temperature to 35 ℃, the inner diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com