Air filtering device for furniture processing

An air filter device and furniture technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of debris, powder and gaseous VOC that are not easy to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

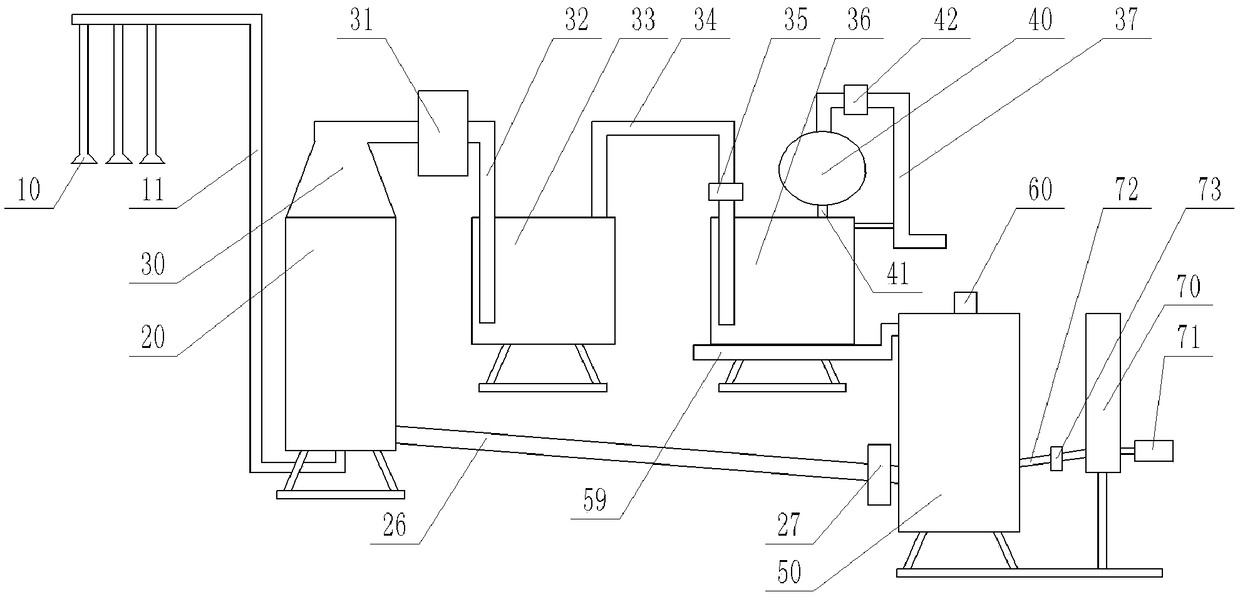

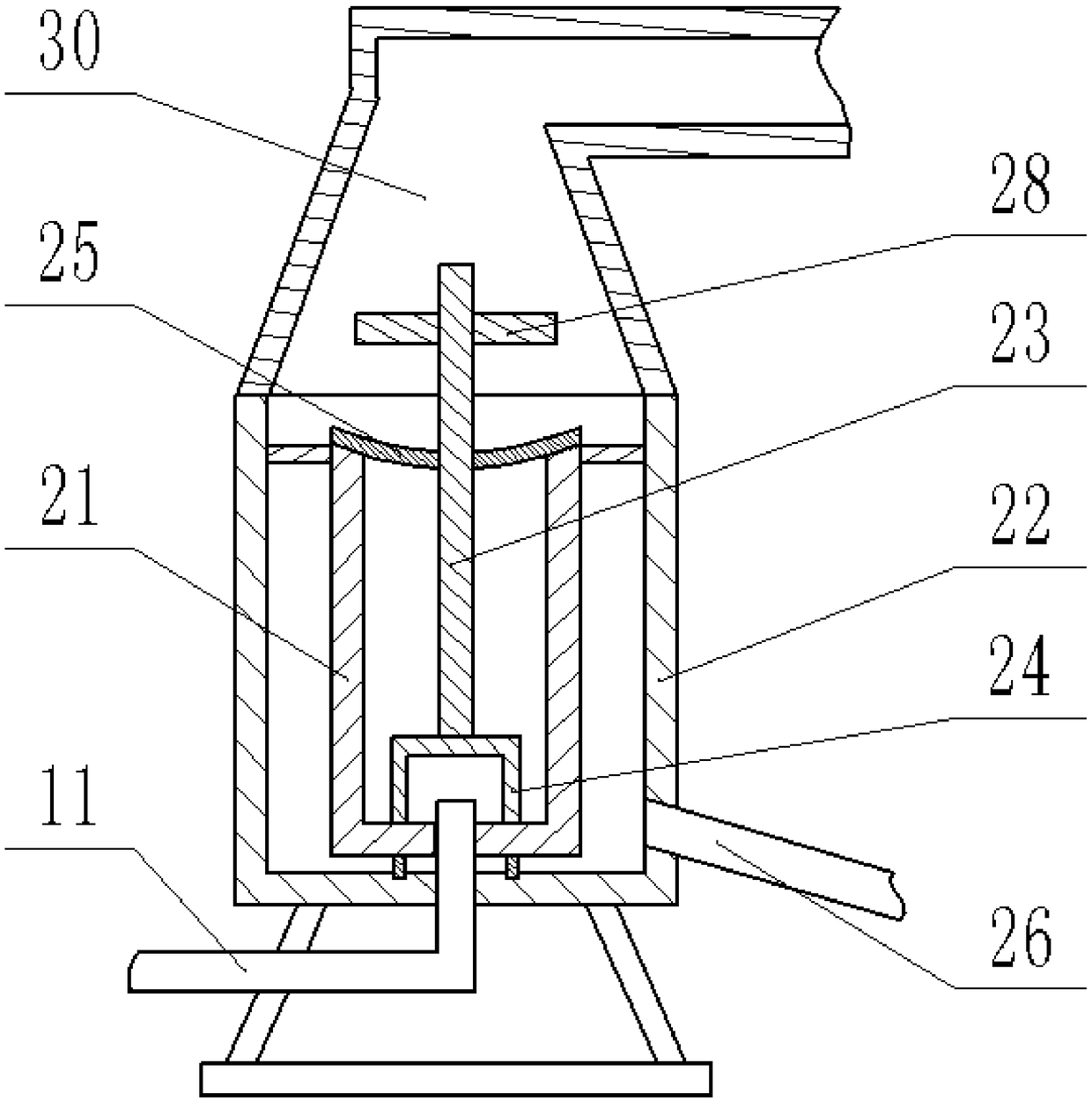

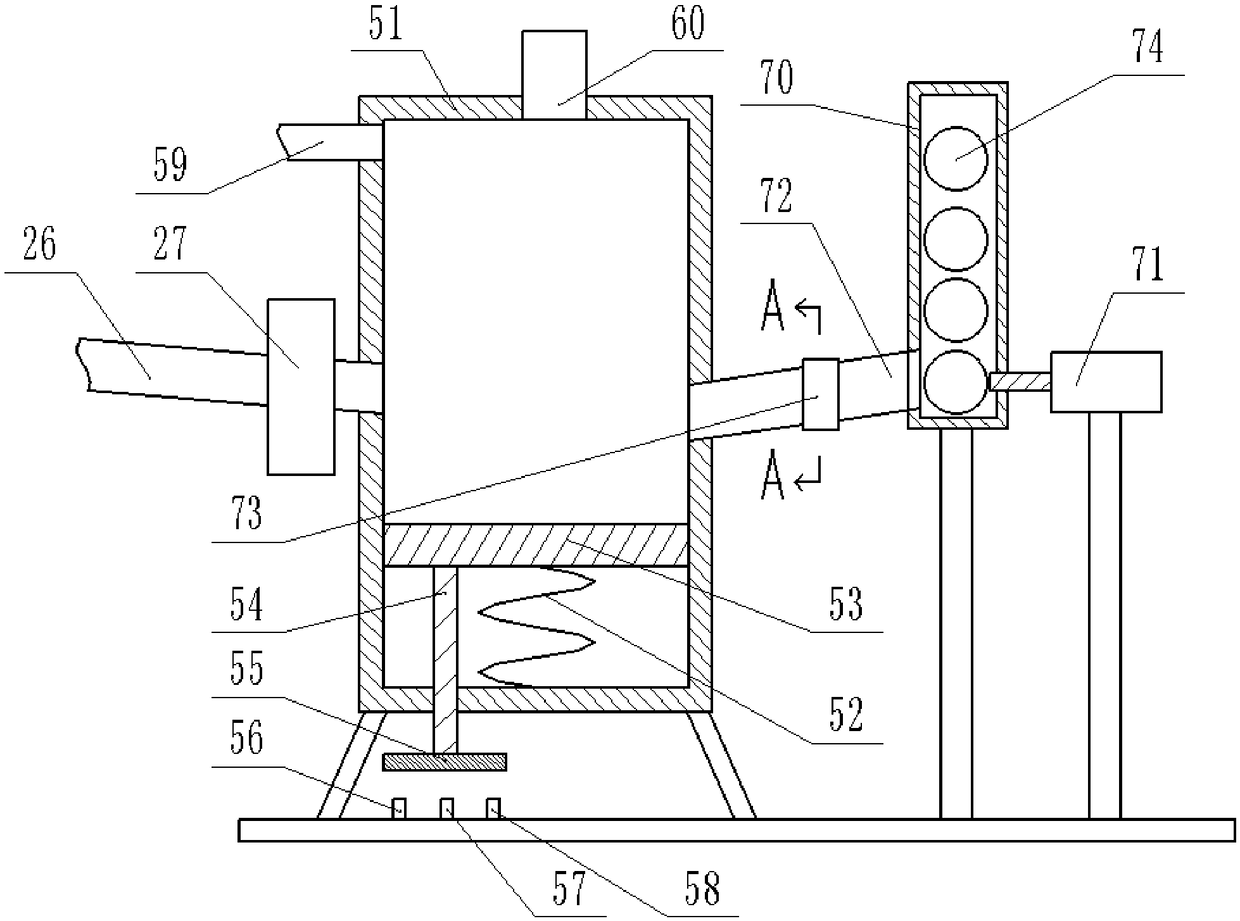

[0023] The reference signs in the drawings of the description include: gas collecting hood 10, gas collecting pipe 11, centrifugal barrel 20, inner barrel 21, outer barrel 22, rotating shaft 23, connecting rod 24, screen 25, inlet channel 26, first valve 27 , wind blade 28, air inlet pipe 30, exhaust fan 31, air outlet pipe 32, first filter box 33, first air guide pipe 34, one-way valve 35, second filter box 36, second air guide pipe 37, air bag 40, Branch pipe 41, pressure valve 42, incinerator 50, furnace body 51, spring 52, sliding plate 53, ejector rod 54, top plate 55, first switch 56, second switch 57, third switch 58, flue 59, fire outlet 60. Storage chamber 70, cylinder 71, delivery pipe 72, second valve 73, combustion ball 74, valve body 80, square groove 81, baffle plate 82, electromagnet 83.

[0024] Such as figure 1 As shown, the present embodiment is an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com