Transthoracic bicuspid valve balloon dilatation catheter assembly and technology thereof

A technology for dilating catheters and balloon catheters, applied in balloon catheters, catheters, dilators, etc., can solve the problems of complex operation, high medical risk, troublesome remedial measures, etc., and achieves simple manufacturing process, simple clinical operation, and avoidance of damage. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

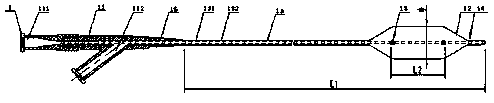

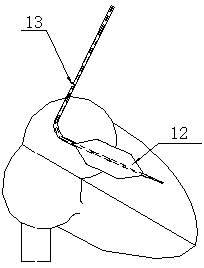

[0035] Such as figure 1 and figure 2 As shown, a transthoracic mitral valve balloon dilatation catheter assembly includes a balloon catheter 1 and a guide bougie 2. One end of the balloon catheter 1 is a handle 11, and the other end is a balloon 12. The handle 11 and the The balloon 12 is connected through a catheter part 13, and the inner catheter 131 of the catheter part 13 is sleeved inside the outer catheter 132; the handle 11 is Y-shaped, and the handle 11 includes a guide wire cavity 111 and a filling cavity 112, and the guide wire cavity 111 communicates with the inner catheter 131 of the catheter part 13, and is used to pass through the guide bougie 2. The filling cavity 112 is a cavity formed by the outer wall of the inner catheter 131 and the inner wall of the outer catheter 132, and is used for filling the narrowed area of the balloon 12. Mitral valve; the distal end of the outer catheter 132 is connected to the proximal end of the balloon 12, the inner catheter...

Embodiment 2

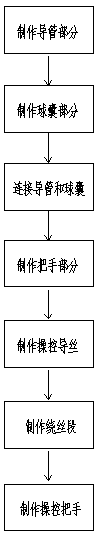

[0046] Such as Figure 5 Shown, a kind of technique of transthoracic mitral valve dilatation catheter assembly comprises the following steps:

[0047] a. Make the catheter part: put the Pebax pellets in the drying cylinder of the precision extruder, set the drying temperature to 75°C, and the drying time to 4h-6h, then set the extrusion temperature to 230°C, and the extrusion pressure to 50MPa, and then extrude Out of molding, to obtain the inner catheter and outer catheter;

[0048] b. Make the balloon part: put the nylon catheter into the forming mold and heat it to 230°C, then take it out and cool it for 3 minutes to make balloons of various specifications according to clinical needs;

[0049] c. Connecting the catheter and the balloon: melt the connecting part of the catheter and the balloon through a hot-melt machine;

[0050] d. Make the handle part: inject polycarbonate material into a Y-shaped handle, and glue it to the catheter;

[0051] e. Manipulating the guide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com