Method for preparing vanadium dioxide film through inorganic sol-gel method

A technology of vanadium dioxide and inorganic sol, which is applied in the field of vanadium dioxide film materials prepared by inorganic sol-gel method, can solve the problems of high price and unsuitability for practical application, achieve low cost, facilitate large-area preparation, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

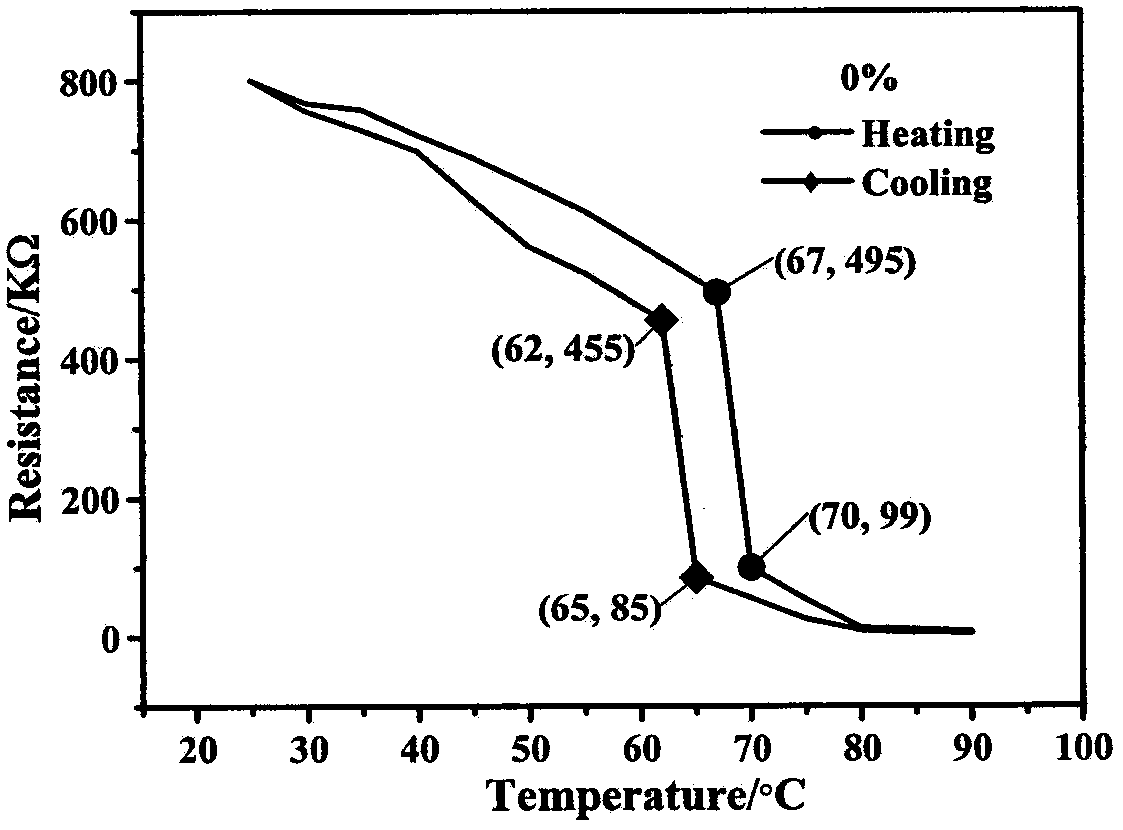

Embodiment 1

[0030] (1) Preparation of precursor: Weigh 5g of V 2 o 5 Powder, first pour it into an agate mortar for full grinding to make the particles more refined. Then pour it into a small crucible, put it into a muffle furnace and heat it up to 820°C to melt it, keep it warm for 30 minutes, quickly take it out and pour it into 200ml deionized water and stir it quickly, wait until it is completely dissolved and dispersed, and wrap it with a plastic wrap Seal it and let it age.

[0031] (2) Cleaning of the substrate: Put the quartz glass sheet in acetone and absolute ethanol for 30 minutes, then put it in dilute hydrochloric acid solution for ultrasonic cleaning for 1 hour, rinse it with deionized water after taking it out, and dry it with nitrogen spare.

[0032] (3) Coating by pulling method: select the sol obtained in the above step (1), and coat with a pulling machine. Set the pulling speed to 2000 μm / s, the dipping time to 100s, and the residence time to 100s. After pulling on...

Embodiment 2

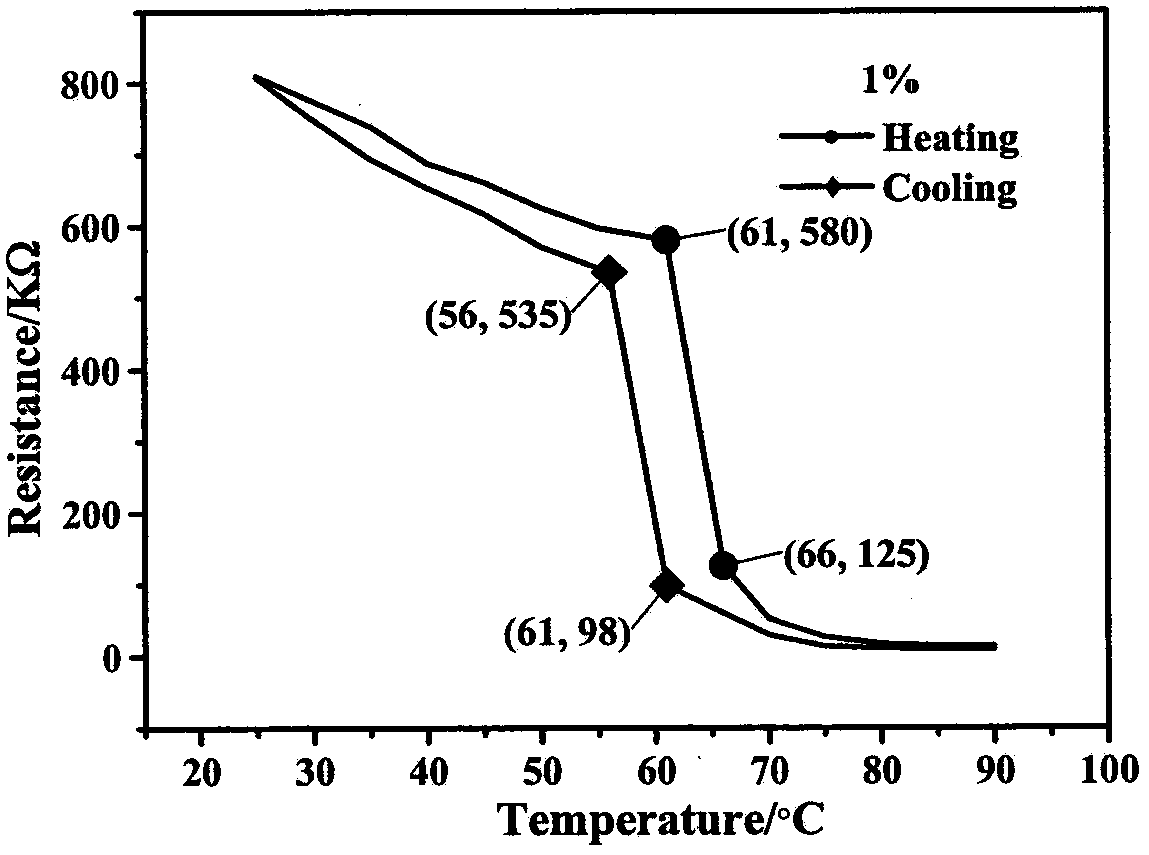

[0036] Precursor preparation: Weigh 5 g of V 2 o 5 , 1.4394 g of MoO 3 (mixed with 1 at.% molybdenum) powder, first pour it into an agate mortar for full grinding, so that the particles are finer and mixed evenly. Then pour it into a small crucible, put it into a muffle furnace and heat it up to 820°C to melt it, keep it warm for 30 minutes, quickly take it out and pour it into 200ml deionized water and stir it quickly, wait until it is completely dissolved and dispersed, and wrap it with a plastic wrap Seal it and let it age.

[0037] Subsequent cleaning of the substrate, pull method coating, and annealing treatment are the same as those in Embodiment 1, and will not be repeated here.

[0038] image 3 It is the relationship diagram of the resistance of the molybdenum-doped vanadium dioxide thin film obtained in Example 2 as a function of temperature. It can be seen from the figure that the resistance at room temperature is about 810KΩ, and then, as the temperature increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com