Thermosetting vinyl organic silicon resin composition and application thereof in high-frequency circuit board

A technology of vinyl silicone and resin composition, which is applied in the direction of circuit substrate materials, printed circuits, printed circuit manufacturing, etc., and can solve the problem of not meeting the requirements of the adhesion of copper-clad laminates, the dielectric loss of the substrate is not low enough, and the substrate layer In order to achieve the effects of excellent thermal and oxidative aging resistance, low dielectric loss and low water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

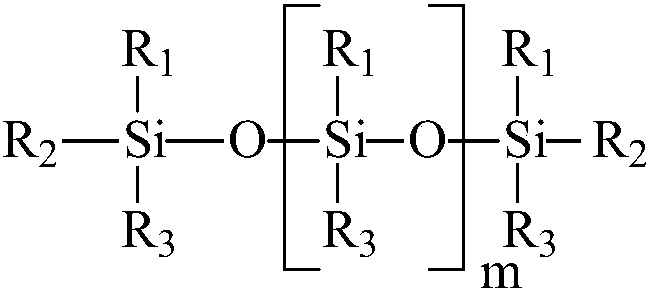

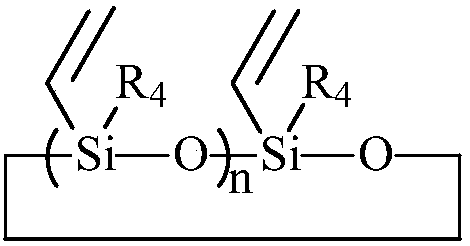

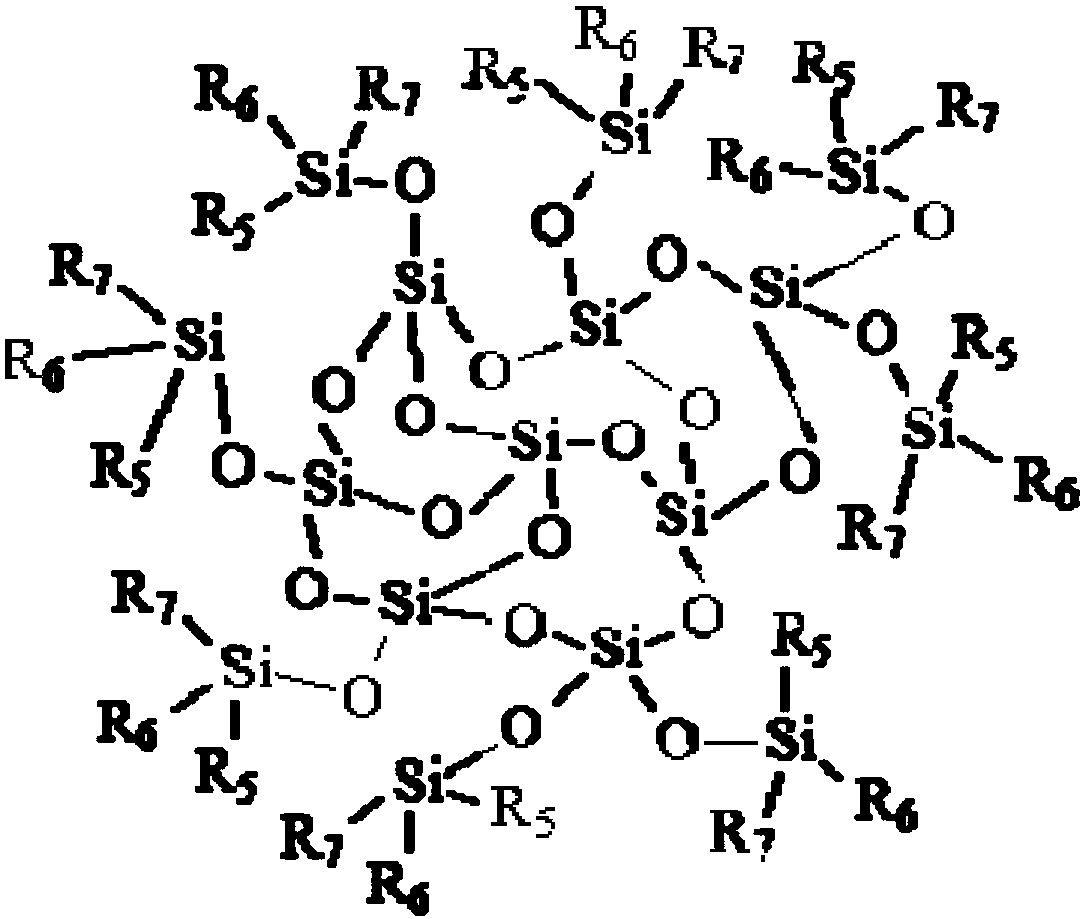

Method used

Image

Examples

Embodiment 1

[0088] 80.0 parts by weight of three-dimensional random network structure MQ vinyl silicone resin DY-VMQ102, 20.0 parts by weight of vinyl modified polyphenylene ether resin SA9000, 3.0 parts by weight of free radical initiator DCP, 233.0 parts by weight of silicon Micropowder 525, dissolved in toluene solvent, and adjusted to a suitable viscosity. Use 2116 glass fiber cloth to impregnate the resin glue solution, pass the nip shaft to control the suitable single weight, and dry it in an oven to remove the toluene solvent to obtain 2116 prepreg. Overlap 4 sheets of 2116 prepreg, with copper foil of 1OZ thickness on the upper and lower sides, vacuum lamination and curing in a press for 90min, and the curing pressure is 50kg / cm 2 , the curing temperature is 200°C, and a high-frequency circuit substrate is obtained. The comprehensive performance of the substrate is shown in Table 2.

Embodiment 2

[0090] 80.0 parts by weight of linear vinyl silicone resin DMS-V05, 20.0 parts by weight of vinyl modified polyphenylene ether resin SA9000, 3.0 parts by weight of free radical initiator DCP, 233.0 parts by weight of silicon micropowder 525, dissolved in toluene solvent and adjust to a suitable viscosity. Use 2116 glass fiber cloth to impregnate the resin glue solution, pass the nip shaft to control the suitable single weight, and dry it in an oven to remove the toluene solvent to obtain 2116 prepreg. Overlap 4 sheets of 2116 prepreg, with copper foil of 1OZ thickness on the upper and lower sides, vacuum lamination and curing in a press for 90min, and the curing pressure is 50kg / cm 2 , the curing temperature is 200°C, and a high-frequency circuit substrate is obtained. The comprehensive performance of the substrate is shown in Table 2.

Embodiment 3

[0092] The cyclic vinyl silicone resin WD-V4 of 80.0 parts by weight, the vinyl modified polyphenylene ether resin SA9000 of 20.0 parts by weight, the free radical initiator DCP of 3.0 parts by weight, the microsilica powder 525 of 233.0 parts by weight, are dissolved in toluene solvent and adjust to a suitable viscosity. Use 2116 glass fiber cloth to impregnate the resin glue solution, pass the nip shaft to control the suitable single weight, and dry it in an oven to remove the toluene solvent to obtain 2116 prepreg. Overlap 4 sheets of 2116 prepreg, with copper foil of 1OZ thickness on the upper and lower sides, vacuum lamination and curing in a press for 90min, and the curing pressure is 50kg / cm 2 , the curing temperature is 200°C, and a high-frequency circuit substrate is obtained. The comprehensive performance of the substrate is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com