A kind of preparation method of rare earth sulfide and/or rare earth sulfur oxide coloring agent

A technology of rare earth sulfur oxides and rare earth sulfides, which is applied in the preparation/treatment of rare earth metal compounds, rare earth metal sulfides, fibrous fillers, etc., and can solve the problem of many impurities, unstable cerium sulfide color, and uneven particle size and other problems, to achieve the effect of high brightness, easy automatic filling, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

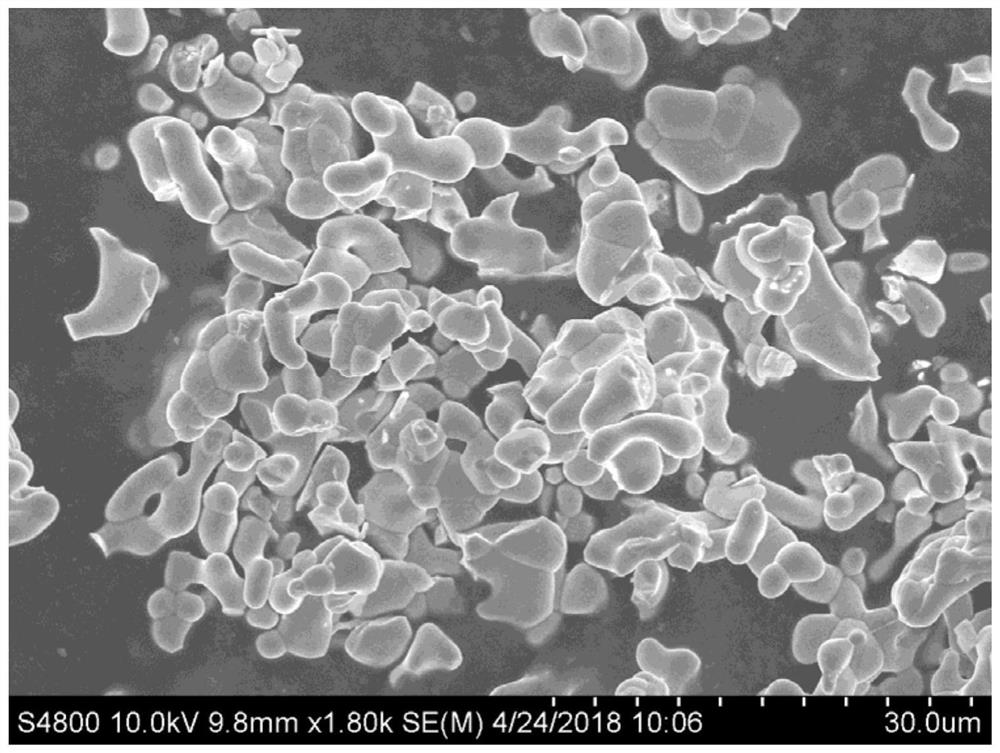

Embodiment 1

[0037] The present embodiment provides a kind of method of producing cerium sulfide coloring agent, comprises the steps:

[0038] (1) Take 0.05mol of cerium carbonate, 0.25mol of sulfur, 0.003mol of lithium carbonate, 0.5mol of polyethylene glycol 500 and 0.1mol of ammonium fluoroborate, respectively, and dry them at 115°C for 130min to obtain the raw materials after drying;

[0039] (2) Carry out dry grinding and stirring of each raw material after drying under the condition of 35r / min for 270min, so as to fully mix and evenly obtain the mixed material;

[0040] Put the mixed material into a mold of a certain size and press it into a mold, set the pressure value of the press to 10Mpa, the automatic pressure supplement value is 0.3Mpa lower than the set value, and the pressurization speed before contacting the powder is 0.5mm / s , after contacting the powder, the speed of pressurization is 0.2mm / s, and the holding time is 10min. After the pressing work is completed, the pressur...

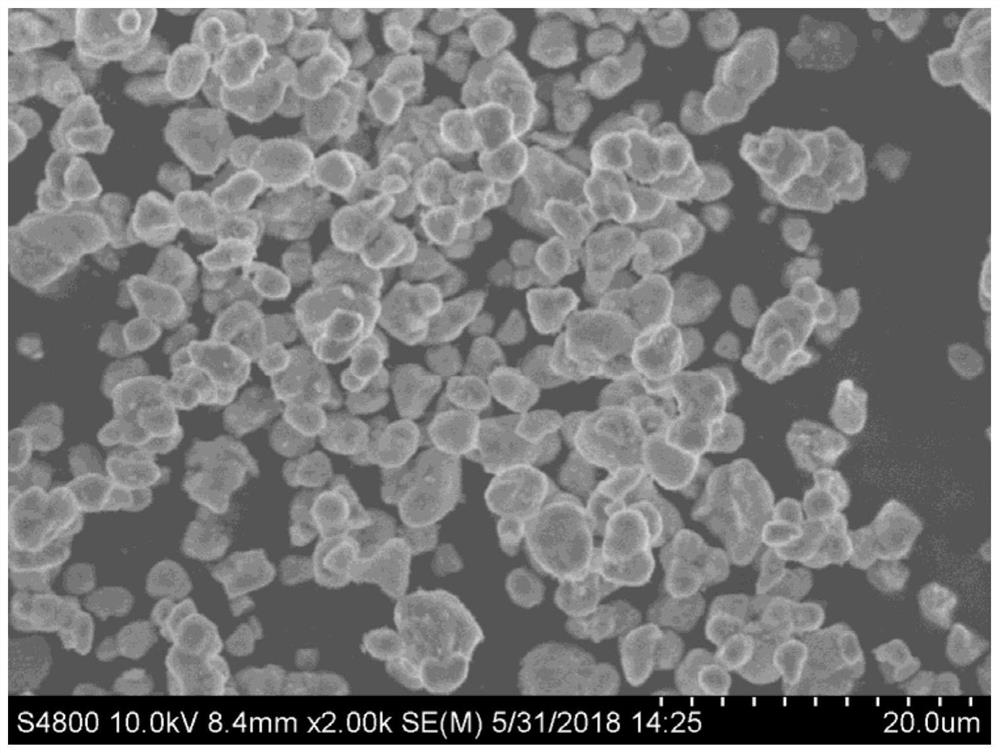

Embodiment 2

[0043] The present embodiment provides a kind of method of producing samarium oxysulfide and samarium sulfide mixed coloring agent, comprises the steps:

[0044] (1) Take 0.05mol samarium carbonate, 0.2mol sulfur, 0.015mol sodium carbonate, 0.0005mol methyl cellulose and 0.005mol potassium fluoroborate, respectively, and dry them at 125°C for 110 minutes to obtain the raw materials after drying;

[0045] (2) Add water to each raw material after drying and carry out wet grinding for 240 min under the condition of 45 r / min, so as to fully mix and evenly, and spray dry at 220 ° C to obtain a mixed material;

[0046] Put the mixed material into a mold and press it into a mold, set the pressure value of the press to 20Mpa, the automatic pressure supplement value is 0.3Mpa lower than the set value, and the pressurization speed before contacting the powder is 0.3mm / s. The post-pressurization speed is 0.1mm / s, and the pressure holding time is 0.5min. After the pressing work is complet...

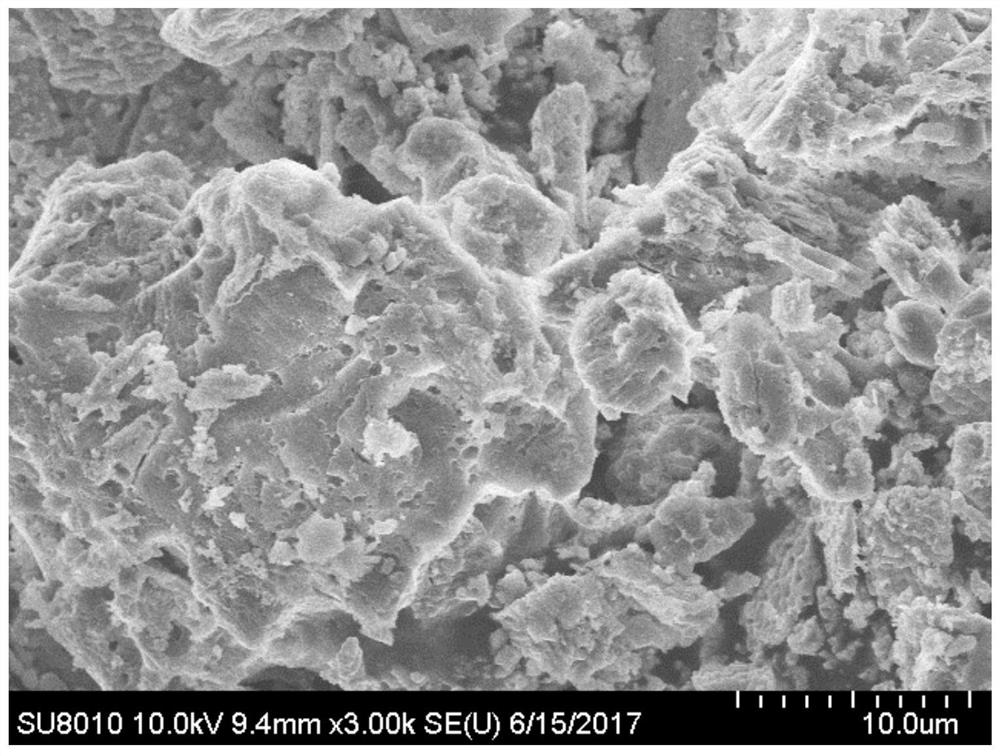

Embodiment 3

[0049] The present embodiment provides a kind of method of producing cerium sulfide coloring agent, comprises the steps:

[0050] (1) Take 0.05mol cerium oxide, 0.2mol sulfur, 0.015mol sodium silicate, 0.02mol hydroxypropyl methylcellulose and 0.01mol sodium fluoroborate, respectively, and dry them at 120°C for 120min to obtain raw materials after drying;

[0051] (2) Add water to each raw material after drying, and carry out wet grinding for 60 minutes under the condition of 40r / min, so that it is fully mixed and uniform, and spray-dried at 210°C to obtain a mixed material; the mixed material is put into a mold and pressed into shape, Set the pressure value of the press to 17Mpa, the automatic pressure supplement value is 0.3Mpa lower than the set value, the pressurization speed before contact with the powder is 0.5mm / s, and the pressurization speed after contact with the powder is 0.2mm / s, The pressure holding time is 4 minutes. After the pressing work is completed, the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com