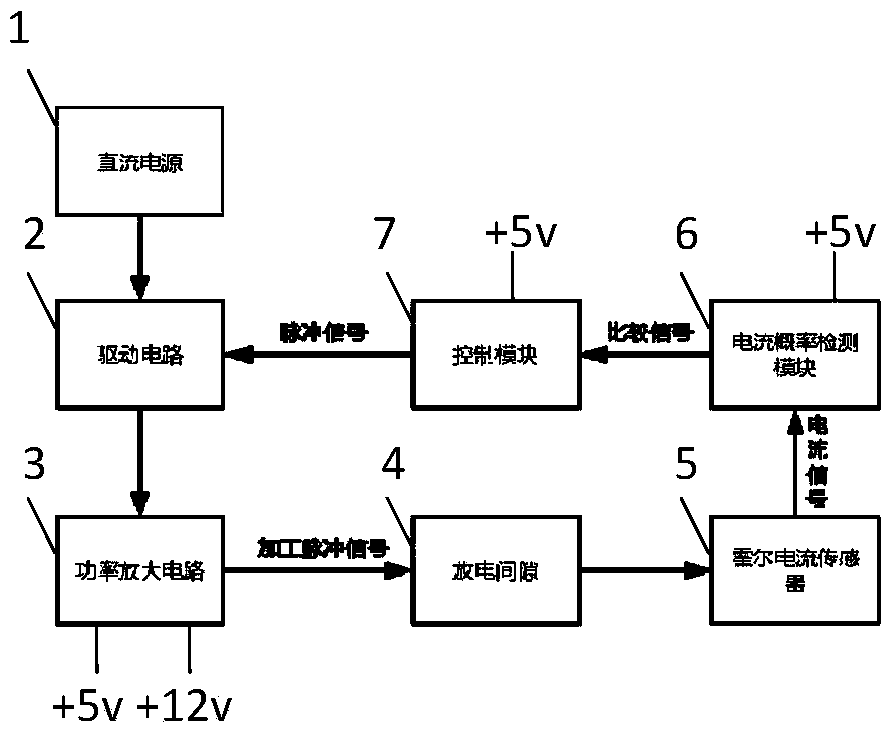

Wire electrical discharge interpulse or pulse-width PID control constant current probability pulse power supply

A technology of electric discharge wire and pulse power supply, which is applied in the direction of circuits, manufacturing tools, electric processing equipment, etc., can solve the problems that general wire cutting machine tools cannot realize automatic and stable semiconductor processing, and achieve stable automatic cutting, stable output waveform, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

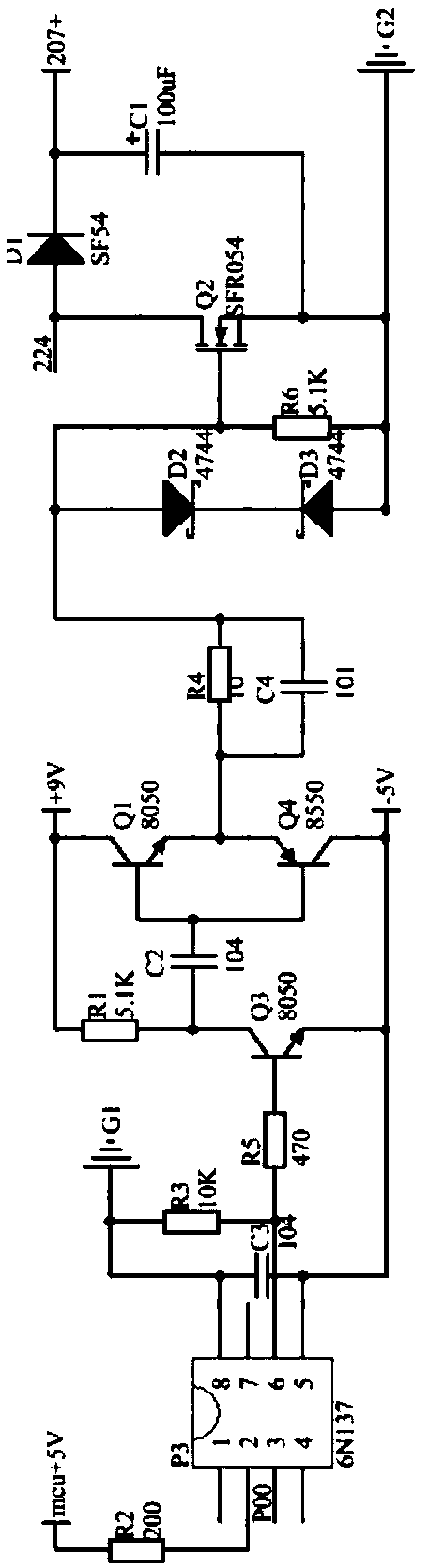

Method used

Image

Examples

example

[0049] Using traditional WEDM machine tools and power sources to cut monocrystalline silicon materials, the servo system fails during the processing, so only constant speed cutting can be performed. The processing parameters shown in Table 1 below are used, and the cutting speed is set to 60 μm / s. Due to semiconductor The volume resistance and processing barrier are still high, and the feed is still at a constant speed during short circuit, so the workpiece is seriously bent, and the processing quality and shape accuracy are very poor.

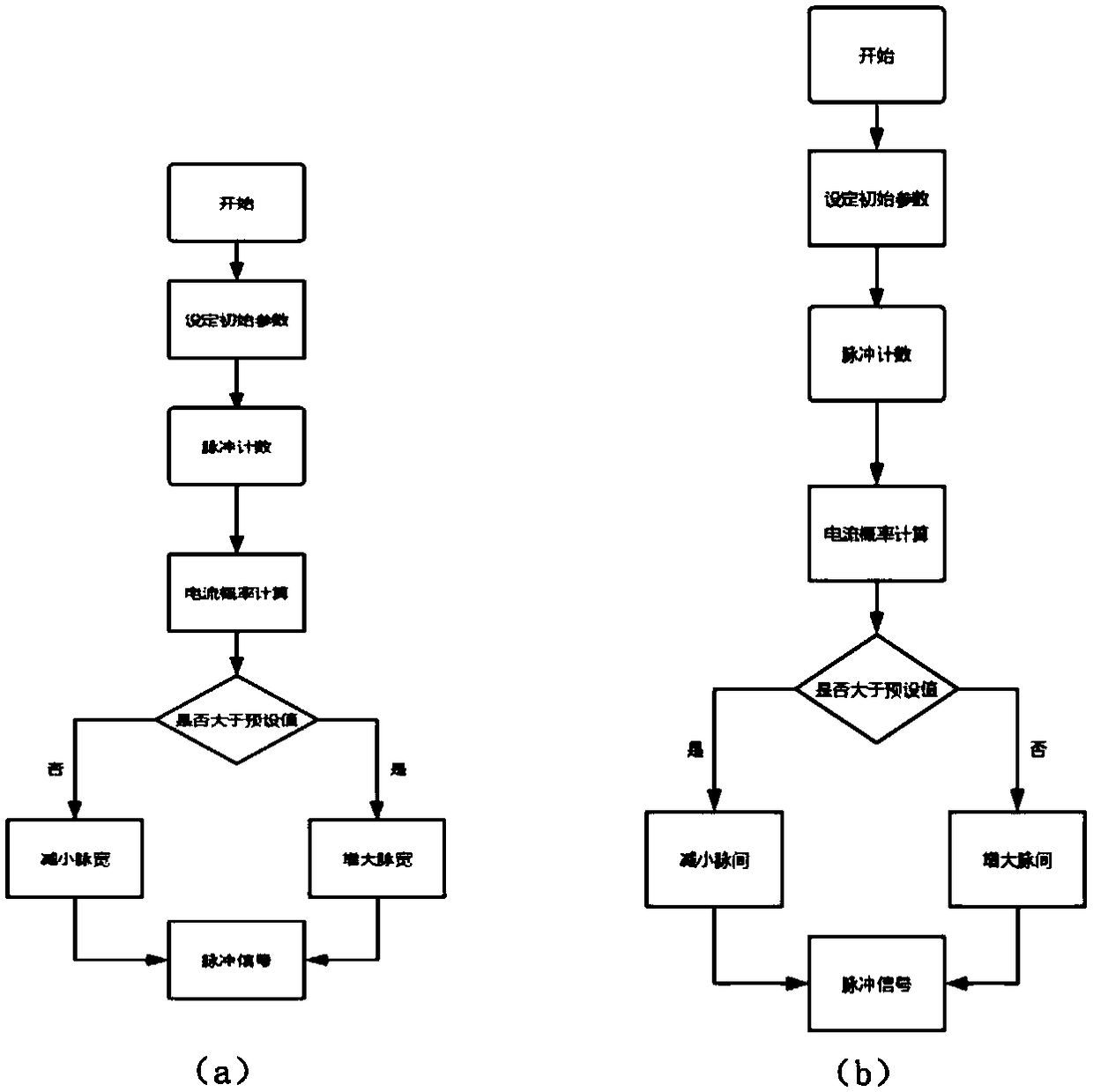

[0050] Change the power supply of the machine tool to the constant current probability pulse power supply designed by the present invention, and also use the processing parameters in the following table 1 for cutting, and set the target discharge probability to 75%. During the processing, the feed rate is still 60μm / s and feed at a constant speed. At this time, the power supply can adjust the pulse interval / pulse width by calculating the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com