A step-feed mill prototype for automatic wet cleaning and drying of abrasive tools

A technology of a sample grinding machine and a feeding mechanism, which is applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of easy cross-contamination of samples, time-consuming and laborious, and manual cleaning, etc., to improve the grinding work. Efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

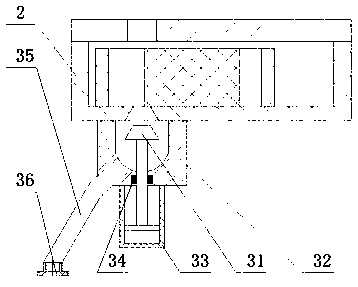

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

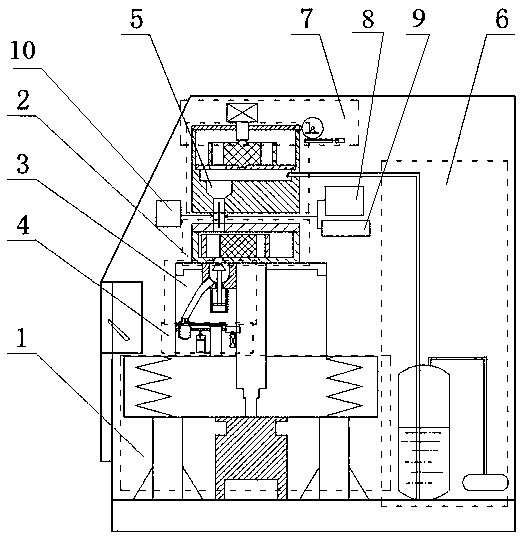

[0032] Such as figure 1 As shown, a step-feed grinding prototype machine for automatic wet cleaning and drying of abrasive tools, including: grinding mechanism 1, unloading mechanism 3, conversion mechanism 4, feeding mechanism 5, high-pressure water supply mechanism 6, and pressing mechanism 7. Humidity sensing module 8 , control module 9 and drying module 10 .

[0033] The grinding mechanism 1 is driven by a motor. When the motor rotates at high speed, the strong centrifugal force and vibration force generated by the eccentric block installed on the shaft make the vibrating steel body generate an exciting force, and the grinding bowl pressed on the vibrating steel body forms vibration and vibration. Grinding function.

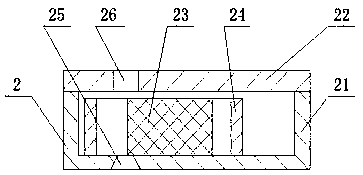

[0034] figure 2 It is a schematic diagram of the structure of the material bowl, and a sealed material bowl 2 is arranged above the grinding mechanism 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com